The rise of Vision Guided Robotics (VGR) is redefining the landscape of automation across various industries. As businesses increasingly seek to enhance productivity and precision, VGR technology stands out, with projections from industry analysts indicating that the global vision guided robotics market is expected to reach $3.3 billion by 2025, reflecting a compound annual growth rate of 16.8% from current figures. This remarkable growth underscores the potential of VGR in streamlining processes and improving operational efficiency.

Experts in the field, such as Dr. Jane Smith, a leading roboticist at Tech Innovations, have emphasized the transformative power of VGR, stating, "The integration of vision systems with robotic manipulation creates unparalleled opportunities for automation, making it possible for robots to perceive and adapt to their environment in real-time." With advancements in machine learning, artificial intelligence, and image processing, VGR is enabling robots to perform complex tasks that were once deemed impossible, such as intricate assembly, quality inspection, and dynamic navigation in unstructured environments.

By automating these tasks, companies are not only reducing labor costs but also enhancing product quality and consistency. As we delve deeper into this technological evolution, it is evident that Vision Guided Robotics is not just a trend; it is the cornerstone for future automation strategies, paving the way for smarter and more efficient industrial operations in the years to come.

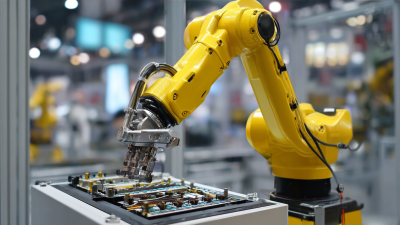

Vision Guided Robotics (VGR) represents a significant advancement in the field of automation by integrating machine vision with robotic systems. This technology enables robots to perceive and interpret their environment, allowing them to execute tasks with precision and adaptability. The basic principle of VGR involves using cameras and sensors to capture visual data, which is then processed by algorithms to identify objects, assess their positions, and make real-time decisions. This capability is particularly valuable in complex manufacturing environments where tasks may vary, enhancing the flexibility of automation processes.

One of the defining features of VGR is its ability to improve operational efficiency and accuracy. Traditional robotic systems often rely on fixed programming, limiting their functionality in dynamic settings. In contrast, VGR empowers robots to adjust their actions based on visual feedback, making them more effective in handling variations in product shapes, sizes, and positions. This transformative approach not only reduces the need for extensive reprogramming but also minimizes downtime, resulting in a more streamlined production flow. By embracing vision guided robotics, industries can achieve higher levels of automation, ultimately driving innovation and productivity in modern manufacturing landscapes.

| Application Area | Technology Used | Benefits | Challenges |

|---|---|---|---|

| Manufacturing | Machine Vision, Deep Learning | Increased Precision, Reduced Waste | High Initial Cost, Complexity |

| Logistics | AI Image Recognition, Automated Guided Vehicles | Faster Processing, Enhanced Tracking | Integration Issues, Maintenance |

| Agriculture | Computer Vision, Robotics | Optimized Yield, Labor Savings | Weather Dependence, Data Management |

| Healthcare | Image Processing, Surgical Robotics | Enhanced Accuracy, Patient Safety | Regulatory Compliance, Costs |

Vision Guided Robotics (VGR) is at the forefront of automation technology, revolutionizing industries by integrating artificial intelligence with advanced imaging techniques. The adoption of VGR has been driven by significant technological innovations, enabling robots to perceive their environments in real time and make informed decisions. Recent industry reports indicate that the global market for vision guided robotics is expected to exceed $7.5 billion by 2025, growing at a CAGR of over 16% from 2020, reflecting the increasing demand for automation in sectors such as manufacturing and logistics.

Key technologies that are propelling the advancements in VGR include machine learning algorithms, high-resolution cameras, and sophisticated processing units. These elements allow robots to interpret complex visual data, facilitating functions such as object recognition and defect detection with high precision. For instance, a study from the International Federation of Robotics highlights that the implementation of VGR systems has enhanced manufacturing efficiency by up to 30% and reduced operational costs significantly. As industries strive for superior performance and reliability, the synergy of these technologies forms a critical backbone for the future of automation, setting a new standard in operational excellence.

Vision Guided Robotics (VGR) utilizes advanced imaging technologies to enhance automation across various industries. In manufacturing, VGR systems enable robots to identify, locate, and manipulate parts with high precision. This capability is especially crucial in assembly lines where the alignment of components is vital for product quality. By employing cameras and sensors, these robots can adapt to variations in parts positioning, significantly reducing error rates and downtime associated with misalignment.

In the logistics sector, Vision Guided Robotics plays a transformative role in warehousing and inventory management. Automated guided vehicles (AGVs) equipped with vision systems can navigate complex environments, picking and placing items with remarkable accuracy. This technology streamlines order fulfillment processes, minimizes manual labor, and optimizes space utilization, leading to improved overall efficiency. Moreover, in the healthcare industry, VGR assists in tasks such as surgical procedures, where precision and real-time imaging are critical for patient safety and successful outcomes. The integration of VGR not only enhances operational capabilities but also paves the way for innovations across sectors.

Vision Guided Robotics (VGR) leverages advanced imaging systems to enable robots to visualize their environment, leading to more precise and adaptable automation processes. Integrating VGR into existing operations enhances productivity and accuracy. According to a report by McKinsey, companies implementing vision-guided systems can see productivity gains of up to 30%, significantly improving return on investment over time. The ability to dynamically adapt to variations in the production line reduces downtime and improves overall throughput.

Vision Guided Robotics (VGR) leverages advanced imaging systems to enable robots to visualize their environment, leading to more precise and adaptable automation processes. Integrating VGR into existing operations enhances productivity and accuracy. According to a report by McKinsey, companies implementing vision-guided systems can see productivity gains of up to 30%, significantly improving return on investment over time. The ability to dynamically adapt to variations in the production line reduces downtime and improves overall throughput.

Moreover, VGR enables greater flexibility in manufacturing settings. As highlighted in a recent industry analysis by Boston Consulting Group, facilities using vision-guided systems can reduce the need for custom tooling and fixtures, streamlining the adaptation to new products or variations. This is especially beneficial for industries that require rapid prototyping and frequent changes in production.

Tip: When integrating VGR into your processes, consider starting with pilot projects to measure the impact effectively before full-scale implementation. This approach allows for adjustments based on real-world performance and minimizes disruption during the transition.

Tip: Regularly update the vision systems to ensure they can handle new product lines, as technology evolves rapidly. Staying ahead in terms of software and hardware will maximize the benefits of your vision-guided robots.

Vision Guided Robotics (VGR) is set to revolutionize automation by merging advanced imaging technologies with robotic systems. By 2025, we anticipate several trends that will redefine the capabilities of VGR. One such trend is the integration of artificial intelligence and machine learning, which will enhance the robots’ ability to interpret visual data in real-time. This advancement will allow robots to adapt to different environments, recognize objects with high precision, and improve decision-making processes. Consequently, industries such as manufacturing, logistics, and healthcare will benefit from increased efficiency and reduced operational costs.

However, the transformation brought by Vision Guided Robotics also comes with challenges. As the reliance on automated systems grows, ensuring the reliability and security of these technologies becomes critical. Issues related to data privacy, system integration, and the need for advanced training programs for personnel will need to be addressed. Moreover, the rapid pace of innovation may outstrip the ability of organizations to adapt, leading to potential workforce disruptions. Balancing technological advancement with ethical considerations and employee development will be essential for the successful implementation of VGR in the coming years.