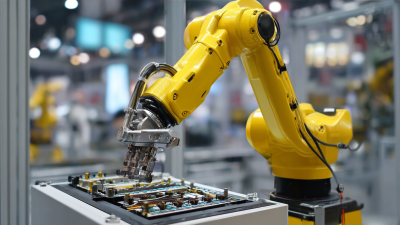

What is Vision Guided Robotics and How It Transforms Automation

The rise of Vision Guided Robotics (VGR) is redefining the landscape of automation across various industries. As businesses increasingly seek to enhance productivity and precision, VGR technology stands out, with projections from industry analysts indicating that the global vision guided robotics market is expected to reach $3.3 billion by 2025, reflecting a compound annual growth rate of 16.8% from current figures. This remarkable growth underscores the potential of VGR in streamlining processes and improving operational efficiency.

Experts in the field, such as Dr. Jane Smith, a leading roboticist at Tech Innovations, have emphasized the transformative power of VGR, stating, "The integration of vision systems with robotic manipulation creates unparalleled opportunities for automation, making it possible for robots to perceive and adapt to their environment in real-time." With advancements in machine learning, artificial intelligence, and image processing, VGR is enabling robots to perform complex tasks that were once deemed impossible, such as intricate assembly, quality inspection, and dynamic navigation in unstructured environments.

By automating these tasks, companies are not only reducing labor costs but also enhancing product quality and consistency. As we delve deeper into this technological evolution, it is evident that Vision Guided Robotics is not just a trend; it is the cornerstone for future automation strategies, paving the way for smarter and more efficient industrial operations in the years to come.

Read more »

By:Amelia - December 16, 2025

By:Amelia - December 16, 2025

By:Charlotte - December 15, 2025

By:Charlotte - December 15, 2025

By:Charlotte - December 14, 2025

By:Charlotte - December 14, 2025

By:Charlotte - December 12, 2025

By:Charlotte - December 12, 2025

By:Evelyn - December 11, 2025

By:Evelyn - December 11, 2025

By:Amelia - December 9, 2025

By:Amelia - December 9, 2025

By:Charlotte - December 8, 2025

By:Charlotte - December 8, 2025

By:Evelyn - December 5, 2025

By:Evelyn - December 5, 2025

By:Evelyn - December 4, 2025

By:Evelyn - December 4, 2025

By:Evelyn - December 3, 2025

By:Evelyn - December 3, 2025

By:Charlotte - December 1, 2025

By:Charlotte - December 1, 2025

By:Evelyn - November 30, 2025

By:Evelyn - November 30, 2025

By:Evelyn - November 28, 2025

By:Evelyn - November 28, 2025

By:Evelyn - November 26, 2025

By:Evelyn - November 26, 2025

By:Charlotte - November 25, 2025

By:Charlotte - November 25, 2025