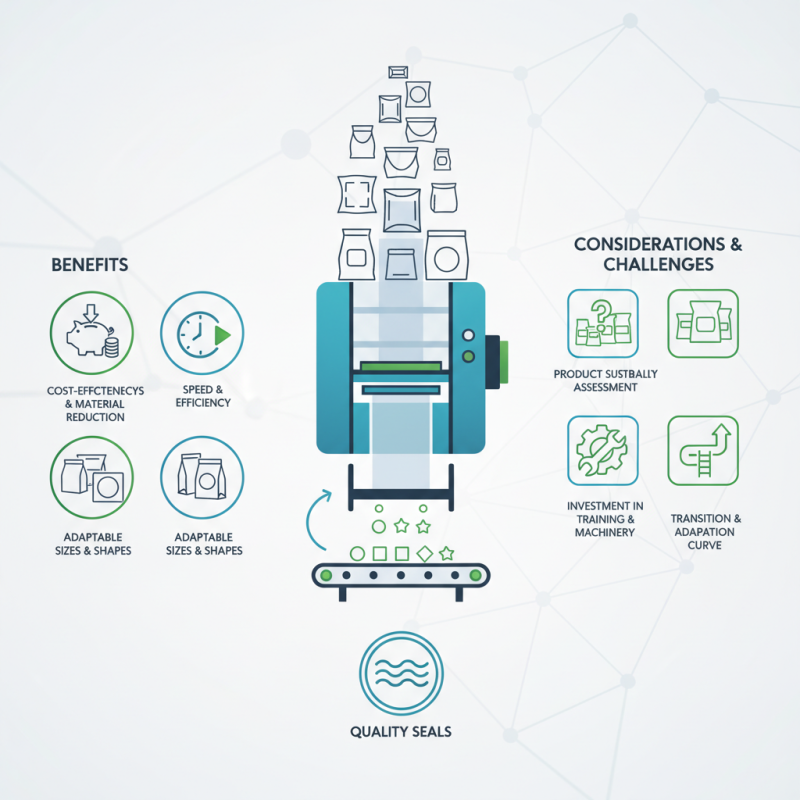

VFFS packaging, or Vertical Form Fill Seal packaging, is revolutionizing the way businesses package their products. This method allows for efficient and adaptable packaging solutions. With VFFS technology, companies can quickly produce bags, creating custom sizes and shapes to meet diverse needs. It’s not just about speed; the quality of the seals is important too.

A notable advantage of VFFS packaging is its cost-effectiveness. By using less material, businesses can save on production costs while still delivering high-quality packages. However, not all products are suited for this type of packaging. Companies must assess their specific requirements before committing to this method.

Adapting to VFFS packaging may present challenges. Some businesses may find it hard to manage the transition from traditional methods. It’s crucial to invest in training and proper machinery. Observing various aspects of operations can lead to better implementation. Recognition of shortcomings during this adaptation phase can help refine processes.

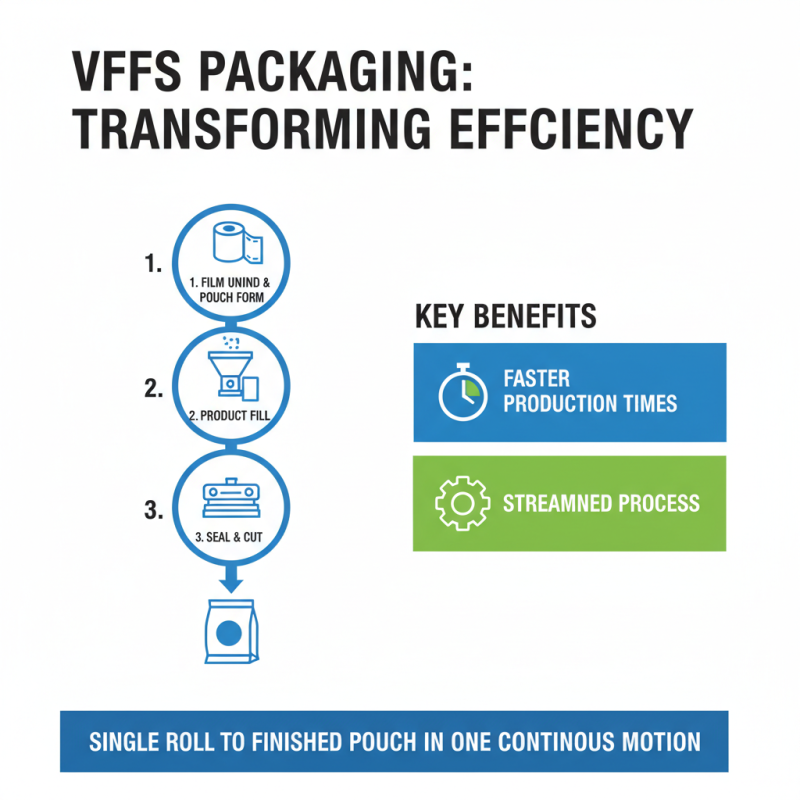

VFFS stands for vertical form-fill-seal packaging. This method converts flat films into bags by filling them with products. It is commonly used in the food, pharmaceutical, and cosmetic industries. The process begins with a roll of flat film, which is formed into a tube. Then, it is filled with the desired product before being sealed. This technique is efficient and highly adaptable.

Tips: Always consider the type of product you are working with. Some items may require special considerations, like moisture barriers or airtight seals. It’s essential to choose the right film material for optimal shelf life.

VFFS packaging allows for high-speed production. Machines can produce thousands of bags per hour. However, it can sometimes lead to product damage due to improper settings. Frequent checks are needed to avoid issues. Regular maintenance ensures that the machinery runs smoothly and efficiently.

Additionally, customizing bag size and shape can cater to specific market needs. Measuring the exact requirements prevents excess waste. Balancing cost-effectiveness and quality is key. Experimenting with various designs may result in unexpected advantages for your products.

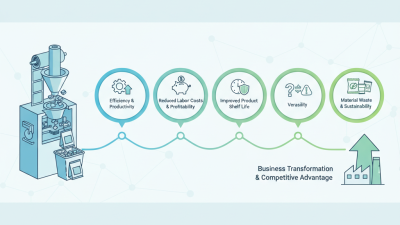

VFFS packaging, or vertical form-fill-seal packaging, offers a range of features that can transform your business's operational efficiency. This technology allows products to be packaged from a single roll of film. It forms a pouch, fills it, and seals it—all in one continuous process. This results in faster production times, which can be a game changer for many businesses.

Efficiency isn’t the only benefit of VFFS. It can handle a variety of products, from grains to snacks. The flexibility of packaging size is a notable feature, allowing companies to adapt quickly to market changes. Yet, it's not without challenges. Sometimes, the machine settings require fine-tuning to ensure optimal sealing. If not properly calibrated, it may lead to waste or spoilage.

Moreover, VFFS systems can require significant upfront investment. While they may save costs in the long run, businesses must assess their specific needs. Investing in the right machinery can be daunting. Understanding your product's requirements is crucial, as this directly influences the effectiveness of the packaging solution.

VFFS packaging, or vertical form-fill-seal packaging, is widely adopted in various industries. This method offers unique advantages, particularly in food processing and pharmaceuticals. According to a recent market report, the global VFFS packaging market is expected to reach $8 billion by 2026. This growth reflects its increasing importance across sectors.

One major benefit is speed. VFFS machines produce packages quickly, enhancing production lines. They can produce up to 300 bags per minute. This efficiency can lead to significant cost savings. However, not all businesses can optimize this quick turnaround effectively. Some companies might struggle with equipment maintenance, impacting overall productivity.

Another advantage lies in versatility. VFFS can package liquids, powders, and solids. This flexibility is crucial for meeting diverse consumer demands. Data indicates that 70% of food manufacturers prefer VFFS due to its adaptability. Yet, switching to VFFS requires training. Some teams may face a learning curve, which can slow initial implementation. The balance between speed, cost, and adaptability drives many businesses to reconsider their packaging strategies.

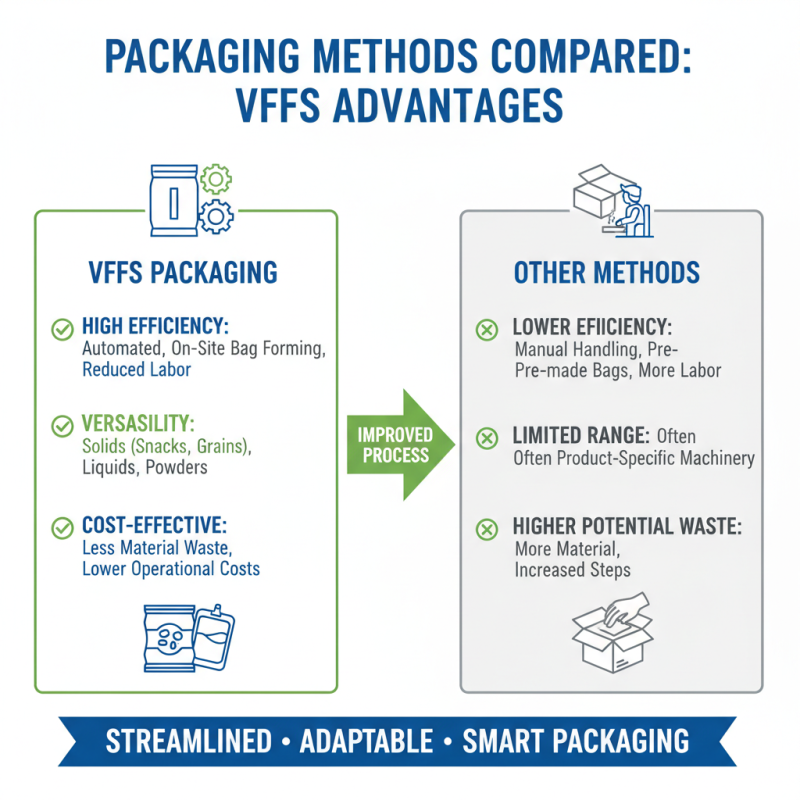

When comparing VFFS (Vertical Form Fill Seal) packaging with other methods, several factors come into play. VFFS is known for its efficiency. It streamlines the packaging process by forming bags on-site. This can reduce labor costs. The machinery automatically fills and seals the packaging. It can handle a variety of products, from snacks to liquids.

In contrast, traditional methods often require more manual labor. This can lead to inconsistencies in quality. It may also slow down production speed. Other methods, like horizontal packaging, take up more floor space. VFFS conserves valuable area in manufacturing.

However, not every business may benefit equally from VFFS. Initial machine costs can be high. Maintenance and technical knowledge are essential. Additionally, the system might not suit all product shapes or sizes. Businesses should weigh these factors carefully. Sometimes, sticking to simpler methods might be more practical. A thorough analysis is crucial for making informed decisions in packaging strategies.

When implementing VFFS (Vertical Form Fill Seal) packaging, several key considerations arise. Your team should evaluate the machinery's compatibility with your product range. Not every machine suits all types of food or non-food items. Accurate specifications can help minimize waste. A mismatch can lead to production downtime and financial loss.

Training is another crucial aspect. Employees must understand the equipment's operations. Familiarity can reduce errors and improve efficiency. Provide hands-on training sessions. Monitor staff performance and encourage feedback. This can reveal hidden issues and areas for improvement. It’s essential to create an open environment for discussion.

Consider the materials used in packaging. Choosing the right film is vital. It should offer durability and barrier properties. This decision impacts shelf life and product integrity. Experimenting with different materials can lead to cost savings. However, it requires time and testing to find the perfect combination. Balancing quality and cost is an ongoing challenge for many businesses. Document your findings for future reference and adaptation.