In the fast-paced world of packaging technology, the VFFS machine stands out as a revolutionary solution for businesses seeking efficiency and precision. Standing for Vertical Form Fill Seal, this machine automates the process of packaging goods, allowing for rapid production speeds while maintaining high-quality standards. Understanding the intricate workings of a VFFS machine is crucial for manufacturers looking to optimize their operations, reduce labor costs, and enhance product shelf life through advanced sealing techniques.

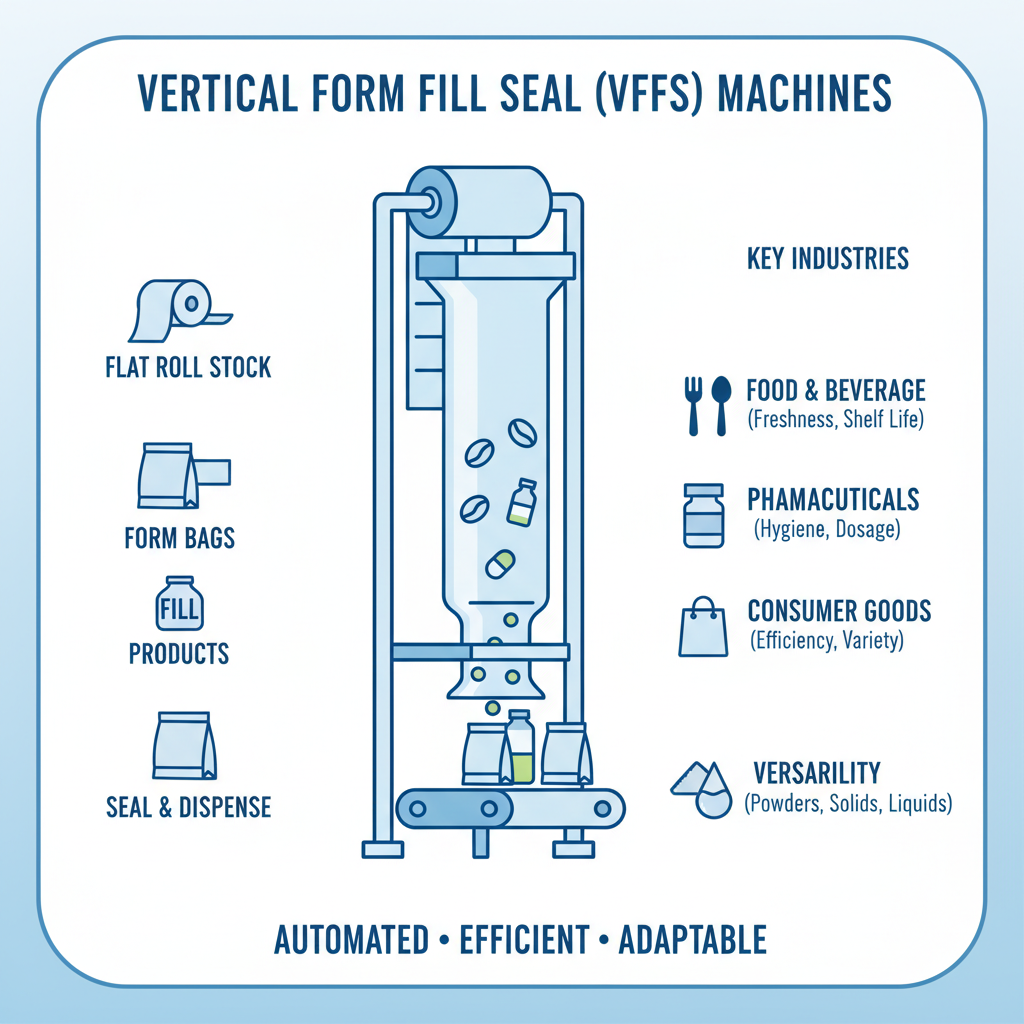

The VFFS machine operates by creating bags from a flat roll of film, filling them with products, and sealing them—all in a continuous vertical motion. This innovative approach not only minimizes material waste but also maximizes space utilization, making it an ideal choice for various industries, from food and beverage to pharmaceuticals. As businesses strive to meet consumer demands for quicker delivery and efficient packaging, comprehending the technology behind VFFS machines becomes increasingly important.

In this overview, we will delve deeper into the functionality, benefits, and applications of VFFS machines, highlighting why they have become a cornerstone of modern packaging solutions. From small-scale operations to large industrial setups, understanding VFFS technology is essential for anyone involved in the packaging process.

A Vertical Form Fill Seal (VFFS) machine is a sophisticated piece of equipment used in packaging processes that create bags from a roll of film. This technology operates on the principle of forming a tube vertically, filling it with products, and sealing it in one seamless motion. VFFS machines are predominantly utilized in the food, pharmaceutical, and consumer goods industries, where speed and efficiency are critical. The ability to adjust the machine to produce various bag sizes and styles makes VFFS a versatile solution for manufacturers looking to optimize their packaging operations.

**Tips:** When selecting a VFFS machine, consider the type of product you are packaging. Certain machines are better suited for powders, granules, or liquids. Additionally, ensure that the machine can accommodate a range of film types, as this will enhance its adaptability for different products.

The efficiency of a VFFS machine not only comes from its design but also from the automation it offers. The integration of sensors and electronic controls allows for real-time adjustments and monitoring, ensuring that the packaging process remains consistent and high-quality. Manufacturers looking to invest in VFFS technology should prioritize models that offer advanced features for better production control.

**Tips:** Regular maintenance is essential to ensure the longevity and optimal performance of your VFFS machine. Create a maintenance schedule that includes routine checks and cleaning of key components to prevent breakdowns and maintain high efficiency in your packaging line.

A Vertical Form Fill Seal (VFFS) machine is essential in modern packaging, primarily used for creating pouches and bags from a roll of film. Understanding its key components can help businesses optimize their packaging processes. The main parts of a VFFS machine include the film supply, forming station, filling system, sealing mechanisms, and the output section. Each of these elements plays a crucial role in ensuring efficiency and product integrity throughout the packaging process.

Tips: When selecting a VFFS machine, consider the film material compatibility, as this can impact the quality of seals and the shelf life of the product. Regular maintenance of the sealing components can prevent costly downtimes and ensure consistent seal integrity.

The forming station is the heart of the VFFS machine, where the flat film is transformed into a three-dimensional pouch. The filling system, which varies among machines, ensures that the right amount of product is accurately dispensed into the pouch. By understanding these components and their functions, manufacturers can tailor their equipment to meet specific packaging needs, enhancing productivity and product presentation.

| Component | Description | Function |

|---|---|---|

| Film Roll | Material used to form the package | Provides the packaging material |

| Forming Collar | Device that shapes the film into a tube | Creates the structure of the pouch |

| Filling System | Mechanism for dispensing product into the pouch | Fills the package with contents |

| Sealing Unit | Applies heat and pressure to seal the pouch | Ensures the package is airtight |

| Cutting Mechanism | Cuts the sealed pouch from the film | Separates individual packages |

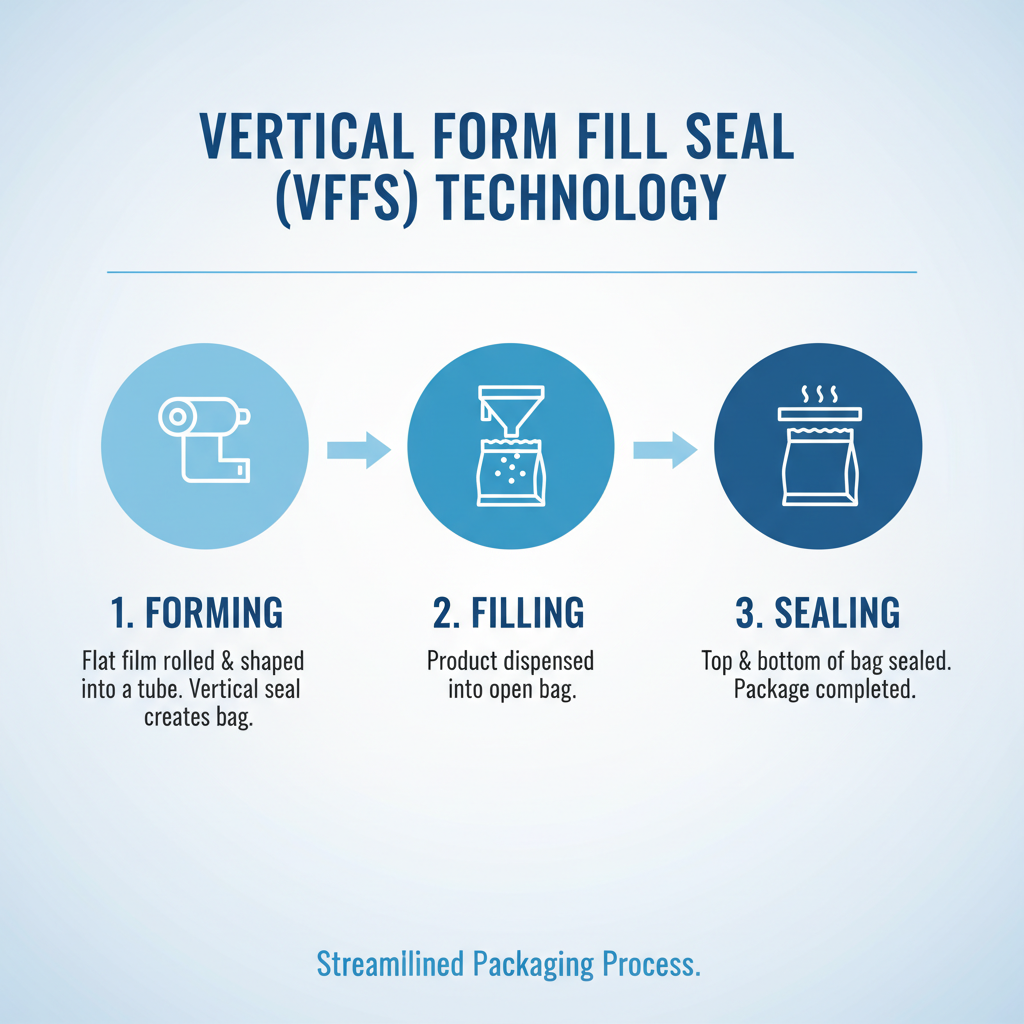

Vertical Form Fill Seal (VFFS) technology is a widely used packaging method that streamlines the process of creating packages from a roll of flexible film. The working principle of VFFS involves three key steps: forming, filling, and sealing. Initially, the flat roll of film is fed into the machine, where it is shaped into a tube. Using a set of vertical sealing jaws, the machine seals the edges of the tube to create a bag.

Once the bag is formed, the next step is filling it with the desired product. This can include a range of items, from food products to non-food items like pharmaceuticals. The filling mechanism can vary, utilizing either volumetric or weight-based methods to ensure that the correct amount of product is dispensed into each package. After filling, the bag is sealed at the top using heat sealing or cold sealing methods, depending on the requirements of the materials being used.

VFFS technology offers significant advantages in terms of speed and efficiency, allowing manufacturers to produce packages at a remarkable rate while maintaining high levels of accuracy and consistency. This technology is essential for modern packaging operations, providing optimal solutions for businesses looking to enhance their production capabilities.

Vertical Form Fill Seal (VFFS) machines play a crucial role in various industries by automating the packaging process. Their ability to produce bags from flat roll stock and fill them with products swiftly makes them indispensable in sectors like food and beverage, pharmaceuticals, and consumer goods. In food packaging, for example, VFFS machines ensure that products are sealed tightly, maintaining freshness and extending shelf life. They are also highly adaptable, capable of handling a wide range of product types, from powders to solids, making them a versatile choice for many manufacturers.

In addition to the food industry, VFFS machines are increasingly being integrated into the pharmaceutical sector, where precision and hygiene are paramount. These machines ensure that medications are packaged securely and labeled accurately, thereby adhering to strict regulatory standards. Furthermore, advancements in technology, such as machine vision and IoT integration, are enhancing the functionality of VFFS machines. This not only increases operational efficiency but also provides real-time monitoring and data analysis capabilities, ultimately leading to improved product quality and reduced waste across multiple industries.

Vertical Form Fill Seal (VFFS) machines have revolutionized the packaging industry by offering efficient, cost-effective solutions for various products. One of the significant advantages of VFFS machines is their ability to streamline the packaging process, reducing labor costs and improving productivity. According to a report by MarketsandMarkets, the global packaging machinery market, which includes VFFS technology, is projected to reach $50 billion by 2025, highlighting the increasing demand for automated packaging solutions.

Another key benefit of VFFS machines is their versatility. These systems can handle a wide range of materials, including films and foils, making them suitable for packaging food, beverages, pharmaceuticals, and other products. In a study by Research and Markets, it was noted that the food and beverage sector accounts for over 60% of the VFFS machinery market, driven by consumer demand for convenient and hygienic packaging options. This adaptability not only meets various industry requirements but also supports the trend towards sustainability, as many modern VFFS machines are designed to use eco-friendly materials.

In terms of operational efficiency, VFFS machines significantly reduce packaging time. They can produce up to 200 packs per minute, which translates to a 40% increase in throughput compared to traditional packaging methods. This efficiency aligns with the rising need for faster turnaround times in the supply chain, as highlighted in the 2021 Smithers Pira report, emphasizing that companies increasingly seek machinery that enhances speed without compromising quality.