In today's competitive manufacturing landscape, efficiency is paramount for success, and one innovative solution that can significantly enhance production workflows is the used vertical form fill seal machine. This remarkable piece of machinery not only offers a cost-effective alternative to new models but also ensures a streamlined packaging process that can elevate output rates by as much as 30%. By automating the packaging of various products, businesses can reduce labor costs, minimize waste, and optimize their operational procedures. The versatility of a used vertical form fill seal machine makes it suitable for a wide range of products, from food items to pharmaceuticals, allowing companies to scale their production without compromising on quality. As we delve deeper into the advantages and functionalities of this equipment, it becomes clear why investing in a used vertical form fill seal machine can be a game-changer for manufacturers looking to maximize efficiency and drive growth.

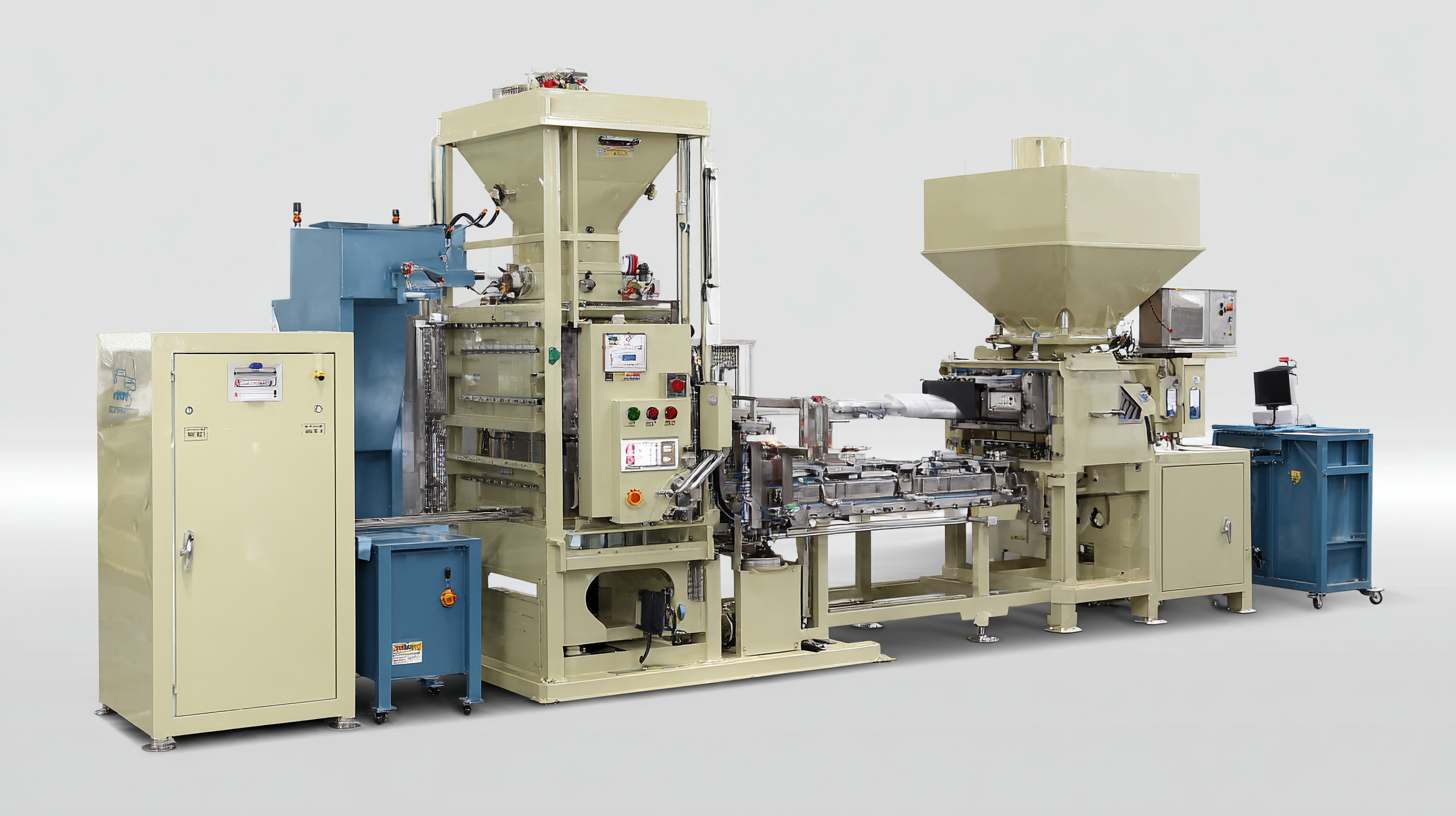

Vertical Form Fill Seal (VFFS) machines are essential in the packaging industry, known for their ability to streamline the packing process efficiently. These machines create bags from a roll of flat film, fill them with product, and seal them—all in one continuous operation. This integrated process not only minimizes labor costs but also enhances the speed at which products are packaged, contributing to a smoother workflow.

Vertical Form Fill Seal (VFFS) machines are essential in the packaging industry, known for their ability to streamline the packing process efficiently. These machines create bags from a roll of flat film, fill them with product, and seal them—all in one continuous operation. This integrated process not only minimizes labor costs but also enhances the speed at which products are packaged, contributing to a smoother workflow.

One of the key features of VFFS machines is their versatility; they can accommodate various bag sizes and styles, including stand-up pouches and pillow bags. They also allow for different types of product filling—from solids and powders to liquids, which makes them suitable for various applications across different industries.

Adding to this is the availability of used VFFS machines, which can deliver significant cost savings while still providing the efficiency and performance needed to improve production rates by up to 30%. By leveraging these machines, manufacturers can achieve more efficient packaging solutions that meet the demands of a fast-paced market.

The impact of used machinery, such as vertical form fill seal machines, on production efficiency is significant and can lead to substantial performance gains. Industry statistics and various case studies highlight that integrating used machinery into existing production lines can improve overall efficiency by up to 30%. This is particularly relevant in sectors where cost management and optimized output are paramount. Companies that have adopted used equipment have reported not only lower capital expenditures but also increased productivity due to the advanced technology used in these machines, which enhances operational speed and accuracy.

Furthermore, the integration of artificial intelligence in manufacturing processes complements the efficiency unlocked by used machinery. AI applications in predictive maintenance, for example, allow manufacturers to proactively address equipment issues before they lead to downtime, further optimizing production capabilities. By leveraging AI alongside upgraded used machinery, organizations can create a more adaptive and responsive production environment. This synergy not only boosts operational efficiency but also positions companies to respond swiftly to market demands, thereby driving competitiveness in the manufacturing landscape.

When evaluating the cost savings between new and used vertical form fill seal machines, manufacturers often find that opting for a used model can significantly enhance their bottom line. New machines come with an appealing warranty and the latest technology, but the initial investment can be prohibitive for many businesses. In contrast, used machines typically cost a fraction of their new counterparts, allowing companies to allocate resources to other vital areas of production.

Moreover, used vertical form fill seal machines are often available in good condition, having undergone rigorous maintenance and inspection. Purchasing these machines not only reduces initial expenditure but also allows for quick integration into existing production lines, minimizing downtime. This efficient transition can help businesses meet demand without incurring the significant costs associated with new equipment while still achieving high productivity gains. Ultimately, the decision to invest in a used vertical form fill seal machine can lead to a substantial increase in operational efficiency and significant cost savings for manufacturers.

| Machine Type | Initial Cost ($) | Average Lifespan (Years) | Production Rate (Units/Hour) | Estimated Annual Savings (%) | Total Cost of Ownership (5 Years) ($) |

|---|---|---|---|---|---|

| New Vertical Form Fill Seal Machine | 50,000 | 10 | 150 | 0 | 75,000 |

| Used Vertical Form Fill Seal Machine | 30,000 | 7 | 130 | 30 | 50,000 |

The demand for used machinery in food and beverage production is on the rise as companies seek cost-effective solutions to enhance their operations. This trend reflects a broader industry shift towards maximizing efficiency while minimizing capital expenditure. The versatility of used vertical form-fill-seal (VFFS) machines plays a significant role in this trend, enabling manufacturers to improve packaging processes and boost production speeds. By integrating these machines, businesses can potentially increase their productivity by 30%, thus meeting the growing need for quick and efficient packaging solutions within the competitive food and beverage sector.

As the food processing market continues to expand at a CAGR of 7.6%, the focus on sustainability and cost-savvy practices drives interest in both new and used machinery. With the global food and beverage processing equipment market projected to reach $111.11 billion by 2032, companies are increasingly recognizing the benefits of investing in used equipment to remain competitive. This shift not only supports economic recovery but also aligns with the industry's commitment to innovation and efficiency, catering to an evolving consumer base that demands higher quality products delivered more swiftly. The landscape of food and beverage production is thus evolving, with used machinery at the forefront of this transformation.

Upgrading to used vertical form fill seal (VFFS) machines offers an excellent opportunity for businesses seeking to maximize their return on investment (ROI). These machines are designed to enhance packaging efficiency while reducing overhead costs. By adopting a high-quality used VFFS machine, companies can streamline their production processes, allowing for more significant output with a smaller investment. This upgrade not only leads to better productivity but also improves product quality and reduces waste, ultimately driving growth in competitive markets.

**Tips for Choosing the Right Used VFFS Machine:**

When selecting a used VFFS machine, consider the specific needs of your production line. Ensure that the machine can accommodate your product size and packaging requirements. Additionally, evaluate the machine's compatibility with existing equipment and processes to minimize disruptions. Don’t forget to check for comprehensive service history and warranties, as this will affect your long-term ROI.

Another vital tip is to assess energy efficiency. Modern VFFS machines are designed to consume less power while maintaining high productivity levels. Investing in energy-efficient models can lead to significant savings on utility bills, contributing positively to your bottom line. By following these guidelines, you can effectively upgrade your packaging operations and capitalize on the advantages that used VFFS machines offer.