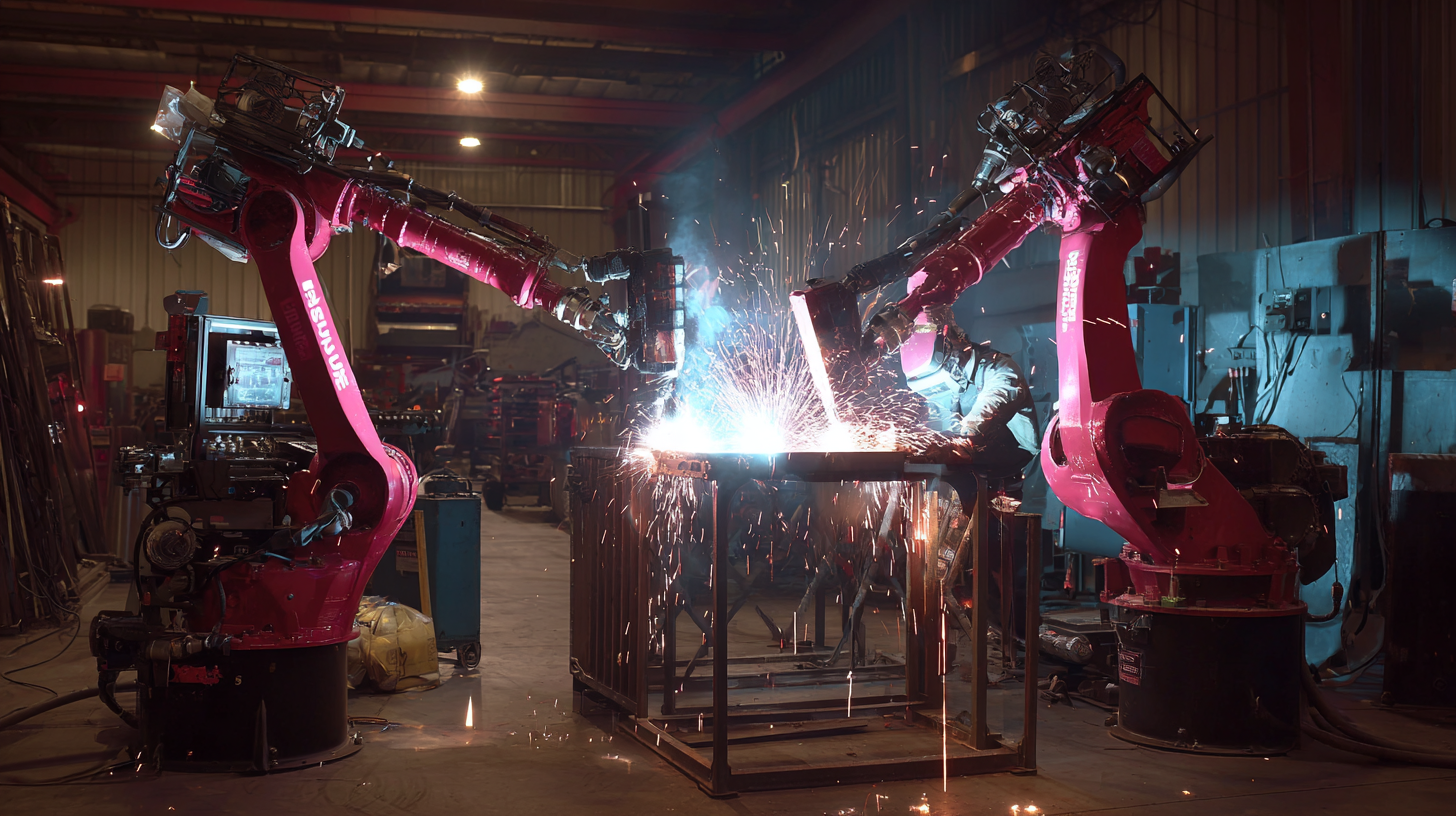

In the ever-evolving landscape of manufacturing, efficiency and precision have become paramount, prompting industries to seek innovative solutions that can keep pace with increasing demands. One significant advancement in this realm is the use of Lincoln Electric robotic welding technology, which is transforming traditional welding processes into highly automated, synchronized operations.

This article delves into the revolutionary benefits provided by Lincoln Electric robotic welding systems, highlighting their capabilities to enhance production output, improve quality, and reduce labor costs. By integrating cutting-edge robotics with digital tools, manufacturers can achieve unprecedented levels of precision and repeatability, ultimately driving competitiveness in the global market.

Whether you're looking to optimize existing workflows or embark on new projects, adopting Lincoln Electric robotic welding solutions can serve as a pivotal strategy in revolutionizing your manufacturing efficiency.

Robotic welding solutions, such as those offered by Lincoln Electric, are transforming the landscape of modern manufacturing by significantly enhancing operational efficiency. One of the primary benefits of robotic welding is its ability to deliver consistent quality and precision in welds, which is essential for maintaining high standards in production. Unlike manual welding, robots can operate continuously with minimal deviations, reducing the risk of human error and ensuring that each weld meets rigorous quality specifications.

In addition to quality enhancement, robotic welding also improves productivity. These systems can function at higher speeds and for extended periods without fatigue, which allows manufacturers to increase throughput and reduce cycle times. Furthermore, the integration of advanced technology, such as artificial intelligence and machine learning, enables robotic systems to adapt and optimize welding processes in real time. This adaptability not only streamlines operations but also leads to cost savings in materials and labor. As industries increasingly adopt robotic welding, the potential for innovation and growth in manufacturing is boundless.

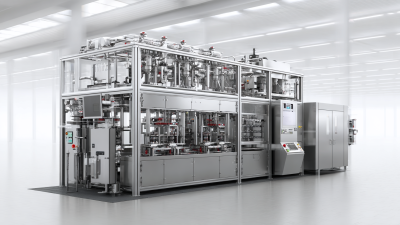

Lincoln Electric's robotic welding solutions are transforming the landscape of manufacturing efficiency by integrating advanced technology with user-friendly features. One of the standout elements of these solutions is their precision and adaptability. According to a report by the International Federation of Robotics (IFR), robotic welding systems can enhance production speeds by up to 30%, significantly reducing operational costs while maintaining superior weld quality. This is crucial in industries where precision and time-to-market are vital.

Another key feature is the intuitive programming interface of Lincoln Electric's robotic systems, which enables operators to set up and modify welding parameters swiftly. This ease of use not only minimizes training time but also allows manufacturers to pivot quickly in response to changing production needs. Statistics from the Robotic Industries Association indicate that companies adopting robotic welding technologies experience a 50% reduction in labor costs, further highlighting the economic advantages of these solutions.

**Tip:** To maximize the efficiency of robotic welding systems, ensure that regular maintenance and software updates are conducted. This will help in maintaining optimal performance and extending the lifespan of the equipment. Additionally, investing in staff training on the latest features can elevate overall production efficacy.

| Feature | Description | Benefits |

|---|---|---|

| High Precision | Advanced sensors and control systems ensure accurate welds. | Reduces material waste and improves overall weld quality. |

| Flexible Programming | User-friendly software allows for quick adjustments and programming. | Enables quick adaptation to different projects and designs. |

| Enhanced Safety | Robotic systems are designed to minimize workplace hazards. | Increases worker safety and reduces incidents on the shop floor. |

| Scalability | Systems can be easily scaled up or integrated with existing setups. | Allows for business growth without significant re-investment. |

| 24/7 Operation | Designed for continuous operation, maximizing productivity. | Increases output and reduces lead times significantly. |

Implementing robotic welding technology can significantly enhance manufacturing efficiency, and a systematic approach is essential for a successful transition. The first step involves thorough planning and assessment of current welding processes. Companies need to analyze production requirements and identify tasks that could benefit from automation. This may involve evaluating the skill set of existing welders and recognizing areas where robotic systems can deliver consistent quality and enhanced productivity.

Once the planning phase is complete, the next stage involves selecting the appropriate robotic welding solutions from Lincoln Electric. It’s crucial to choose the right equipment that matches the specific needs of the manufacturing process, considering factors such as the type of materials, welding techniques, and desired production volume. Following equipment selection, staff training should be prioritized to ensure that operators are proficient in using the new technology. By focusing on these foundational steps, manufacturers can effectively integrate robotic welding technology, leading to improvements in operational efficiency and product quality.

Maximizing production efficiency in manufacturing has become a top priority as industries move towards automation. The robotic welding market is witnessing significant growth, with a projected size expected to rise dramatically in the coming years. By 2035, the laser welding market alone is anticipated to reach USD 4.2 billion, growing at a CAGR of 3.7% from 2025. This surge is fueled by the adoption of advanced welding automation solutions, which streamline processes and enhance productivity.

Implementing robotic welding systems can drastically reduce cycle times and labor costs. For instance, the adoption of automated welding solutions has enabled companies like Stadler to achieve remarkable efficiency gains. By integrating sophisticated robotics, manufacturers can not only improve the quality of their welds but also significantly increase throughput.

Tips for optimizing robotic welding implementation include conducting a thorough analysis of current processes to identify areas where automation can have the most significant impact. Investing in training for staff on new technologies is also crucial, as it empowers teams to manage and maintain systems effectively. Prioritizing scalability in robotic solutions ensures that businesses can adapt to changing production demands and technologies as they evolve.

The integration of robotic welding solutions has proven transformative for manufacturers, as shown in various case studies highlighting efficiency gains and cost reductions. According to a report by the International Federation of Robotics, companies adopting robotic automation in their manufacturing processes reported productivity increases of up to 30%. For instance, a leading automotive manufacturer integrated Lincoln Electric's robotic welding systems into their assembly line, leading to a remarkable 25% reduction in cycle time while maintaining consistent weld quality.

Another compelling case involves a structural steel company that faced challenges with labor shortages and inconsistent welding results. By implementing Lincoln Electric's advanced robotic welding technology, they not only improved their operational efficiency by 40% but also enhanced weld precision, achieving a defect rate decrease of approximately 15%. Industry experts suggest that the demand for skilled welders is on the rise, projected to grow 6% through 2029 according to the Bureau of Labor Statistics. This makes the transition to robotic solutions not only a strategic move for immediate efficiency gains but also a long-term investment in addressing workforce challenges in manufacturing.