In the fast-paced food industry, efficiency is paramount to staying competitive and meeting consumer demands. Recent reports indicate that companies leveraging advanced automation technologies, such as the vertical pouch filling machine, can increase their production rates by as much as 30%. This remarkable enhancement not only streamlines the packaging process but also minimizes labor costs and reduces material waste, contributing to a more sustainable manufacturing approach.

Market research projects the global vertical pouch filling machine market will experience significant growth, driven by the increasing preference for flexible packaging solutions and the rising demand for convenience foods. With the ability to precisely fill, seal, and package various food items, these machines are transforming food production lines. In fact, a study conducted by the Packaging Machinery Manufacturers Institute (PMMI) revealed that businesses employing vertical pouch filling systems reported a dramatic improvement in their overall operational efficiency and product quality, solidifying the role of automation as a key player in the modern food processing landscape.

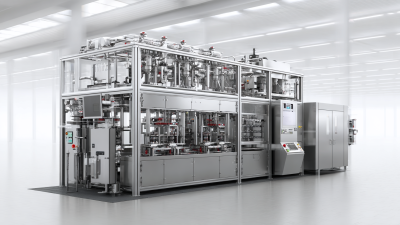

Vertical pouch filling machines have revolutionized the food production sector by offering several significant advantages that enhance efficiency and productivity. These machines are designed to streamline the packaging process, allowing manufacturers to fill and seal pouches rapidly while maintaining high levels of accuracy. With their ability to handle a variety of pouch sizes and materials, vertical pouch filling machines accommodate diverse food products, ensuring that businesses can adapt to changing consumer demands without the need for extensive reconfiguration.

Another key benefit of vertical pouch filling machines is their compact footprint. Unlike traditional packaging systems, these machines require less floor space, making them ideal for facilities with limited room. This space-saving design not only increases the overall production capacity but also reduces operational costs associated with facility management. Additionally, their automated features minimize the risk of human error, leading to consistent product quality and less waste. As a result, food manufacturers can improve their operational workflow and achieve higher output levels while maintaining stringent quality control standards.

The chart above illustrates the significant increase in production efficiency achieved through the adoption of vertical pouch filling machines in the food industry. The data shows an increase from 150 units per hour to 195 units per hour, reflecting a 30% boost in productivity.

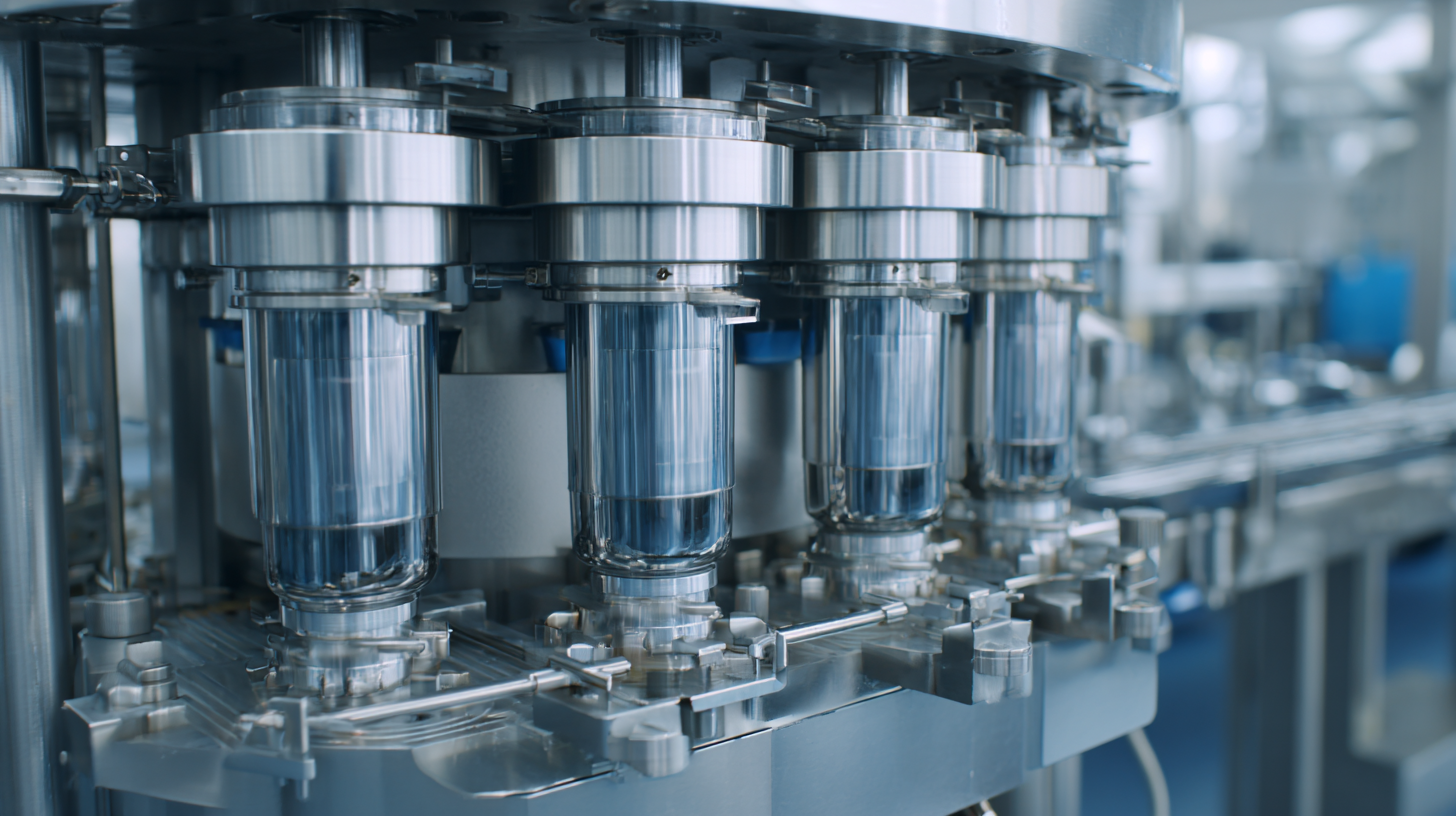

Vertical pouch filling machines have become essential in the food industry, significantly enhancing productivity. One key feature that boosts efficiency is the high-speed filling capability. These machines are designed to fill pouches rapidly, often exceeding traditional methods by utilizing advanced automation and precise control systems. This speed not only increases output but also reduces labor costs and minimizes the risk of human error during the packing process.

Another important feature is the versatility of vertical pouch filling machines. They can handle a wide variety of pouch sizes and types, accommodating various food products, from liquids to powders. This flexibility allows manufacturers to quickly switch between different products, reducing downtime and enabling greater responsiveness to market demands. Additionally, integrated quality control systems ensure that every pouch meets strict safety and quality standards, further streamlining the production process. These innovations collectively contribute to a remarkable 30% increase in production efficiency within the food sector.

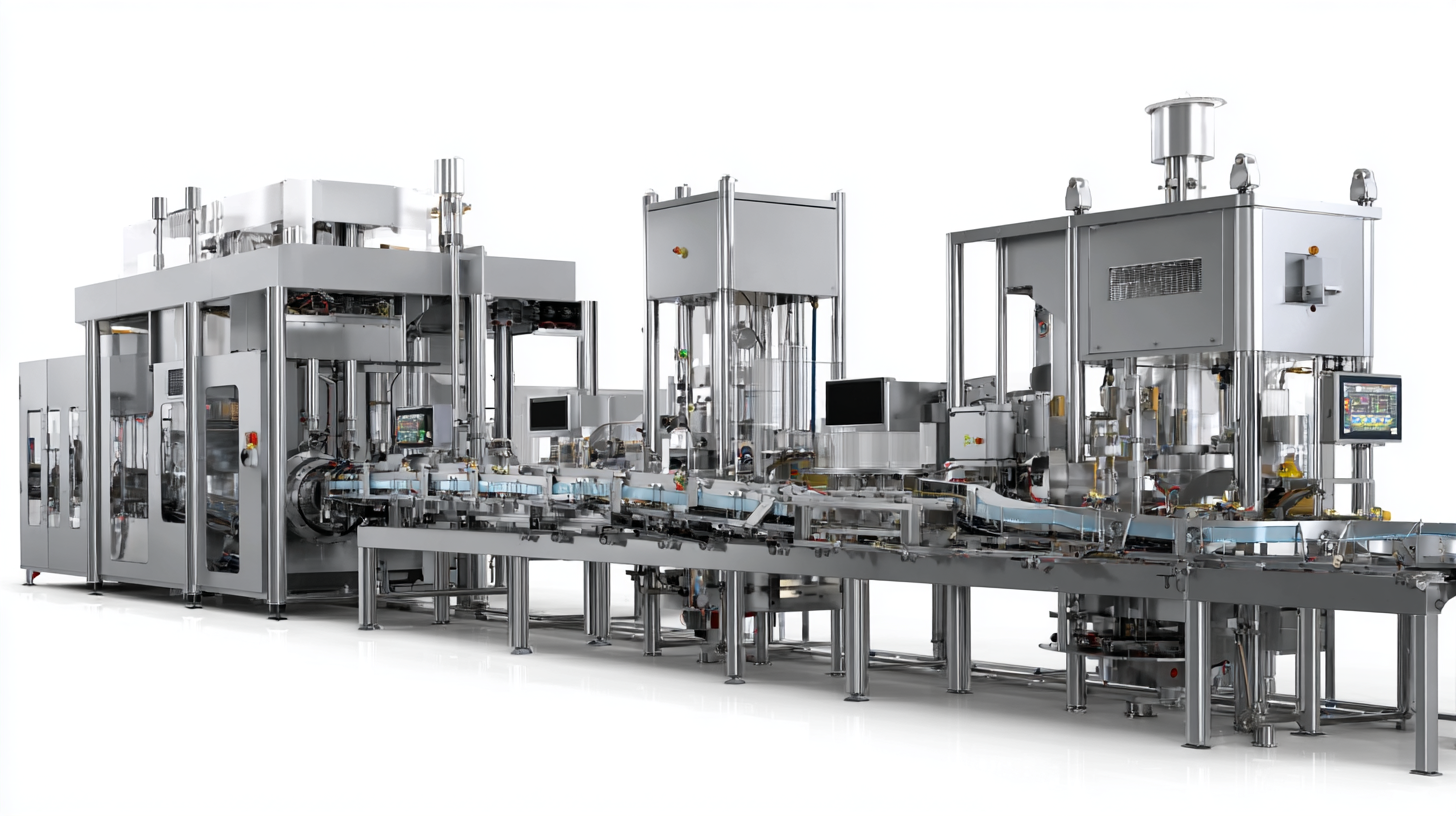

When it comes to pouch filling machines in the food industry, the choice between vertical and horizontal systems can significantly impact operational efficiency. According to a report by Market Research Future, vertical pouch filling machines can increase production efficiency by up to 30% compared to their horizontal counterparts. This is largely due to their ability to handle various pouch sizes and types without extensive changeover times, allowing for quicker production runs and reduced downtime.

**Tips:** When considering pouch filling options, be sure to evaluate the layout of your production line. Vertical machines generally require less floor space due to their design, making them ideal for facilities with limited room. Additionally, look for machines that offer quick-change capabilities for different pouch types, as this can further enhance your production flexibility.

Moreover, vertical machines allow for efficient handling of liquid and semi-liquid products due to their gravity-assisted filling process. This minimizes spills and ensures accuracy, with many models boasting filling accuracies of over 99%. In contrast, horizontal machines may struggle with these materials and often require additional features to maintain efficiency.

**Tips:** Analyze the filling precision performance of different machines when selecting your equipment. Investing in a machine with higher accuracy can significantly reduce product wastage and ensure quality control in your production line.

| Dimension | Vertical Pouch Filling Machine | Horizontal Pouch Filling Machine |

|---|---|---|

| Production Speed (pouches/min) | 120 | 90 |

| Efficiency (%) | 95 | 75 |

| Changeover Time (minutes) | 10 | 15 |

| Space Requirement (sq ft) | 100 | 150 |

| Initial Cost ($) | 75,000 | 70,000 |

| Maintenance Frequency (per year) | 2 | 3 |

In the competitive landscape of the food industry, maximizing production efficiency is critical for success. Recent case studies have shown that implementing vertical pouch filling machines can result in a significant 30% boost in production. For instance, a mid-sized snack manufacturer reported that after switching to a vertical pouch filling setup, they could increase their output while also reducing wastage and labor costs. This positive change led to faster turnaround times, allowing the company to respond more quickly to market demands.

To achieve similar results, companies can consider a few practical tips. First, assess the specific packaging needs of your products and choose a machine that optimally fits these requirements, ensuring flexibility for different sizes and designs. Additionally, regular maintenance of machinery can prevent downtime and keep production running smoothly. Training staff on efficient machine operation also plays a pivotal role in leveraging technology to its fullest potential.

Another case highlighted the experience of a beverage company that integrated vertical pouch filling machines into their workflow, resulting in a marked increase in production speed. They found that the automation capabilities allowed for parallel processing, further enhancing efficiency. Companies aiming to replicate these success stories should not underestimate the importance of investing in cutting-edge technology and processes that align with their growth strategies.

As the food industry continues to evolve, vertical pouch filling technology is at the forefront of innovation, driving efficiency and adapting to changing consumer demands. Emerging trends indicate a shift towards automation and advanced analytics, with machines becoming more sophisticated in handling a variety of pouch sizes and materials. Innovations such as artificial intelligence and machine learning are enhancing the capabilities of these machines, allowing for real-time adjustments that increase accuracy and reduce waste.

Furthermore, sustainability is becoming a key focus in vertical pouch filling technology. Manufacturers are increasingly adopting eco-friendly materials and energy-efficient processes as consumers show a growing preference for sustainable packaging. This trend encourages the development of machines capable of using recyclable and biodegradable materials without compromising on quality or speed. As the food sector embraces these advancements, vertical pouch filling machines are set to not only enhance production efficiency but also align with the industry's sustainability goals, ensuring a more responsible approach to food packaging in the future.