In today’s competitive packaging landscape, businesses are increasingly looking for

innovative solutions to enhance

productivity and reduce costs. According to a report by Smithers Pira,

the global packaging market is expected to reach $1 trillion

by 2024, with a significant focus on efficiency and automation.

Used vertical form fill seal machines have emerged as a vital asset in this quest for

improved packaging outcomes, boasting the potential to increase productivity by up to

30%.

These machines not only streamline the packaging process but also enable companies to adapt

to changing consumer demands rapidly.

With advancements in technology, integrating used vertical form fill seal machines into

existing operations can greatly optimize workflow, minimize labor costs, and significantly

enhance overall operational effectiveness. As organizations strive for higher efficiency

in their production lines, the adoption of these used machines represents a strategic move

to stay ahead of the competition in the dynamic packaging sector.

Used vertical form fill seal machines have emerged as a vital asset in this quest for

improved packaging outcomes, boasting the potential to increase productivity by up to

30%.

These machines not only streamline the packaging process but also enable companies to adapt

to changing consumer demands rapidly.

With advancements in technology, integrating used vertical form fill seal machines into

existing operations can greatly optimize workflow, minimize labor costs, and significantly

enhance overall operational effectiveness. As organizations strive for higher efficiency

in their production lines, the adoption of these used machines represents a strategic move

to stay ahead of the competition in the dynamic packaging sector.

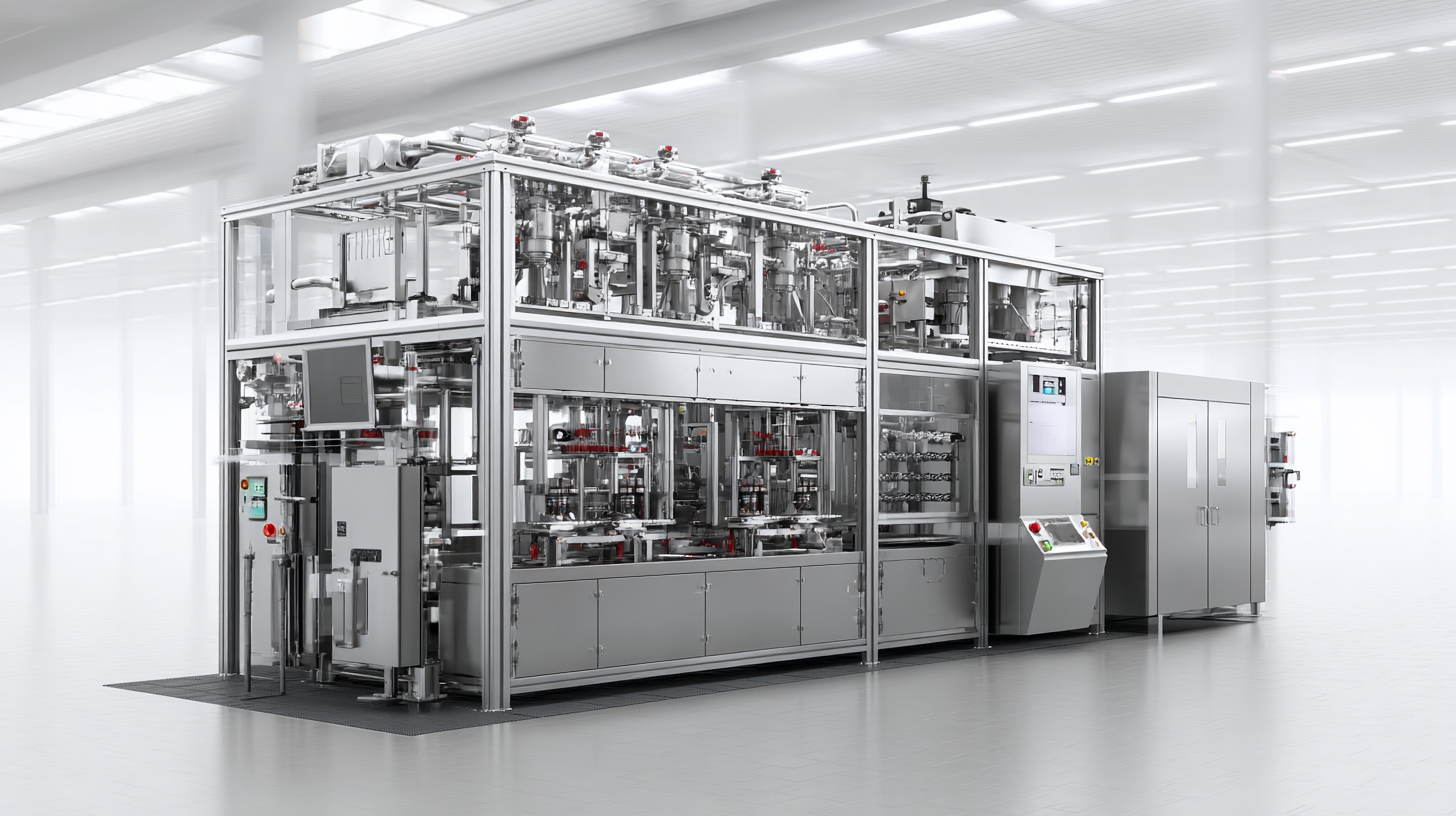

Vertical Form Fill Seal (VFFS) machines have revolutionized the packaging industry,

offering unparalleled advantages that significantly enhance productivity. These machines efficiently combine the processes of

forming, filling, and sealing in a single operation, reducing the time and labor involved in packaging products. With their

streamlined design, VFFS machines can accommodate a variety of package sizes and shapes, making them versatile solutions for different industries, from food to pharmaceuticals.

One of the standout benefits of using VFFS machines is their ability to maintain high-speed production rates while ensuring

consistent quality. By automating the packaging process, manufacturers can achieve a remarkable increase in output, often improving

productivity by as much as 30%. This efficiency is crucial in today’s fast-paced market,

where meeting consumer demand quickly can give companies a significant competitive edge. Additionally, VFFS machines reduce

material waste through precise filling, helping businesses optimize their resources and contribute to sustainability efforts in packaging.

Vertical Form Fill Seal (VFFS) machines have revolutionized the packaging industry by enhancing productivity through innovative mechanisms. These machines operate with a closed-loop system that efficiently manages material flow, ensuring minimal downtime. The continuous film feed utilized in VFFS allows for rapid formation of pouches, drastically reducing the time required for the packaging process. This speed is complemented by precise sealing technology, which minimizes product waste and maximizes output.

Additionally, the integration of advanced automation features in used VFFS machines contributes significantly to operational efficiency. Sensors and programmable logic controllers (PLCs) monitor the packaging cycle in real-time, allowing for immediate adjustments to be made, optimizing performance. The adaptability of these machines to various product sizes and types also plays a critical role in maximizing productivity, making them a versatile choice for manufacturers looking to streamline their packaging processes. By harnessing these mechanisms, businesses can achieve up to a 30% increase in packaging efficiency, transforming their operational capabilities.

This chart illustrates the effect of using vertical form fill seal machines on packaging productivity across various packaging operations.

Vertical Form Fill Seal (VFFS) machines have become instrumental in optimizing packaging processes across various industries. Real-world case studies reveal remarkable outcomes, with companies experiencing up to a 30% increase in productivity by adopting used VFFS machines. These machines streamline the packaging process by combining multiple steps—forming, filling, and sealing—into a single operation, significantly reducing cycle times and labor costs.

When considering upgrading your packaging line, it's essential to evaluate the specifications of used VFFS machines carefully. Ensure that the machine you choose can handle a variety of product sizes and packaging materials. This flexibility allows your operations to adapt to changing market demands without needing extensive modifications.

Additionally, efficiency can be maximized by regularly maintaining the equipment and investing in training for your staff. Proper training ensures that operators fully understand the machine's capabilities and can troubleshoot minor issues before they become major problems. By creating a culture of continuous improvement around machinery use, businesses can further leverage the productivity benefits of VFFS technology.

Investing in used vertical form fill seal (VFFS) machines can significantly enhance packaging productivity while also delivering substantial cost-effectiveness. According to a recent market report by Research and Markets, the global VFFS packaging market is projected to grow at a CAGR of 5.2% through 2027, indicating a sustained demand for efficient packaging solutions. Used VFFS machines can reduce operational costs by up to 30%, as they provide similar performance to new models at a fraction of the price. This translates to an immediate positive impact on a company's bottom line, making them an attractive asset for businesses looking to enhance their production capabilities without incurring high capital expenses.

The return on investment (ROI) associated with used VFFS equipment is also compelling. Studies from packaging industry analysts indicate that companies often recoup their investment within just 12 to 18 months, thanks to lower acquisition costs and increased productivity. With advancements in technology, used machines can now meet stringent quality standards and operational efficiency, outperforming older models. They are ideal for businesses aiming to modernize their packaging lines while mitigating financial risks, ultimately ensuring they remain competitive in a rapidly evolving market landscape.

As the packaging industry continues to evolve, innovations in Vertical Form Fill Seal (VFFS) technology are at the forefront of enhancing efficiency in production lines. According to a recent market report by Smithers Pira, the demand for automated packaging equipment is projected to grow by 5.9% annually, driven in part by advancements in VFFS machines. These machines are now equipped with smart sensors and AI capabilities, allowing for real-time monitoring and adjustments that can reduce material waste and downtime significantly.

Moreover, the integration of Industry 4.0 principles into VFFS technology is fostering a new era of productivity. Recent statistics highlight that manufacturers using modern VFFS systems can achieve a productivity boost of up to 30%. This boost is largely attributed to faster changeover times, improved sealing techniques, and enhanced flexibility in handling various packaging formats. As companies embrace these innovations, they are not only improving their productivity but also adapting to market demands with greater agility and responsiveness. The future of VFFS technology promises even greater enhancements as the industry seeks to meet sustainability goals while maximizing efficiency.