In the rapidly evolving landscape of automation, vision guided robotics has emerged as a transformative force, revolutionizing the way industries approach efficiency and precision. By integrating advanced imaging technologies with robotic systems, businesses can significantly enhance their production capabilities, leading to reduced operational costs and increased throughput. This introduction provides insight into the "Top 10" strategies for effectively implementing vision guided robotics, offering valuable guidance for organizations looking to stay competitive in an increasingly automated world.

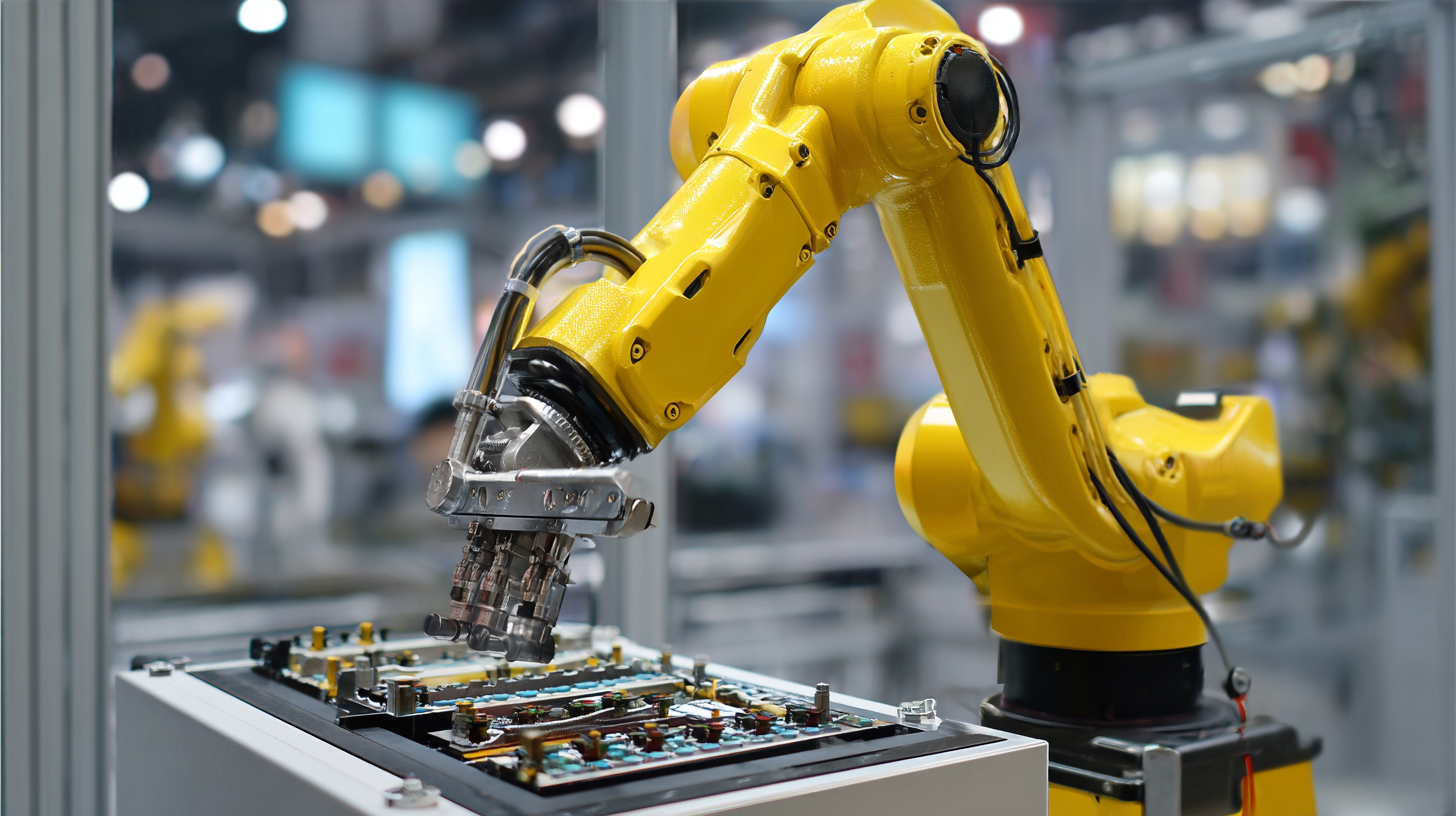

The advent of vision guided robotics not only streamlines manufacturing processes but also enables robots to interact intelligently with their environments. From quality control to complex assembly tasks, these systems leverage real-time visual data to make informed decisions on the fly. By exploring the foundational principles of vision guided robotics, this outline aims to equip businesses with the knowledge necessary to harness this innovative technology, ensuring seamless integration into existing workflows and unlocking unprecedented levels of automation efficiency.

Vision guided robotics (VGR) is revolutionizing automation across various industries by enhancing precision and efficiency. A key component of VGR systems is the combination of advanced imaging technology and machine learning algorithms. With a report by MarketsandMarkets predicting that the global VGR market will grow from $1.80 billion in 2020 to $5.56 billion by 2025, it is evident that industries are increasingly recognizing the value of integrating vision systems into their automation processes.

The effectiveness of VGR is greatly attributed to its ability to perform real-time object recognition and tracking. This capability allows robots to adapt to dynamic environments, making them well-suited for tasks such as assembly, packaging, and quality control. According to a study by McKinsey & Company, companies that implement sophisticated automation strategies like VGR can achieve efficiency gains of up to 30%. These systems not only minimize errors but also reduce downtime, ultimately leading to significant cost savings.

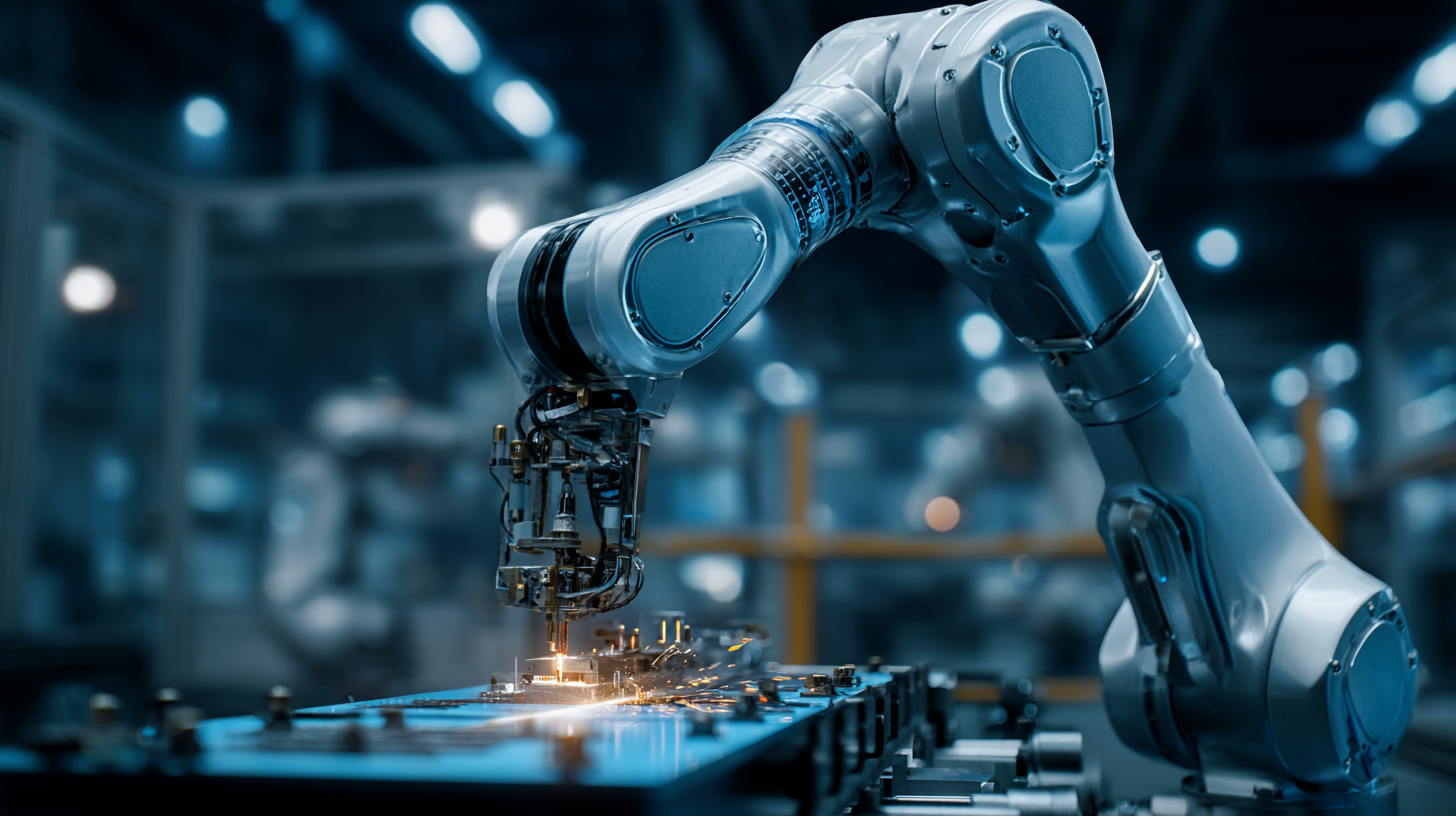

Furthermore, the use of 3D vision technologies is becoming prominent within VGR applications. These systems are capable of interpreting complex spatial data, enabling robots to handle a wide variety of tasks with high precision. An industry analysis by ABI Research highlights that the adoption of 3D vision in robotics can increase productivity by up to 40%, demonstrating the transformative potential of these technologies in modern manufacturing and logistics operations.

The implementation of Vision Guided Robotics (VGR) is revolutionizing automation efficiency across various industries. According to a report from the International Federation of Robotics (IFR), the use of vision systems in robotic applications has seen a dramatic rise, growing at a rate of 14% annually. This technological advancement allows robots to interpret visual information, leading to more precise and flexible responses than traditional automation methods. Industries such as manufacturing, logistics, and agriculture, are harnessing this technology to achieve remarkable productivity gains. For instance, a recent study from McKinsey & Company highlights that automating tasks with VGR can increase operational efficiency by up to 30%.

In addition to productivity improvements, VGR also significantly enhances product quality and reduces waste. A report by Gartner indicates that companies using vision-guided automation have experienced a 25% reduction in defective products. This capability is particularly critical in sectors like food processing and pharmaceuticals, where product integrity is paramount. Furthermore, the ability to adapt to varying tasks with minimal downtime allows businesses to remain agile in a fast-changing market landscape. With projections estimating that the VGR market will reach $12 billion by 2025, industries that adopt this technology are not only optimizing their current operations, but are also setting themselves up for sustained growth in the future.

| Industry | Automation Type | Benefits | Efficiency Improvement (%) | Deployment Time (Months) |

|---|---|---|---|---|

| Manufacturing | Assembly Line | Increased throughput and reduced errors | 30 | 6 |

| Logistics | Sorting and Packing | Faster sorting times and reduced labor costs | 25 | 4 |

| Agriculture | Harvesting | More precise harvesting and reduced waste | 20 | 12 |

| Healthcare | Surgical Assistance | Increased precision and reduced recovery time | 15 | 8 |

| Retail | Inventory Management | Real-time inventory tracking and stock optimization | 18 | 5 |

Implementing vision-guided robotics can significantly enhance automation efficiency, yet it comes with its own set of challenges. One of the primary hurdles in integrating vision-based systems is the complexity of ensuring accurate perception and environment recognition. Robots must be equipped with sophisticated algorithms that enable reliable object detection and tracking, which can vary in performance due to factors such as lighting conditions, object variations, and background clutter. Addressing these concerns often requires extensive calibration and fine-tuning, along with robust software development to handle real-time data processing.

Another challenge lies in the integration of vision systems with existing robotic hardware and software. Disparities in communication protocols and processing capabilities can hinder seamless interaction between vision sensors and robotic controllers. To mitigate these issues, companies can invest in standardized frameworks that facilitate interoperability and scalability. Leveraging advances in artificial intelligence and machine learning can also enhance the predictive capabilities of vision systems, improving their adaptability to dynamic environments. By tackling these challenges head-on, organizations can create more efficient and reliable automated solutions that fully utilize the potential of vision-guided robotics.

The future of automation lies significantly within the realm of vision-guided robotics (VGR). As industries increasingly turn to automation for efficiency and precision, VGR technologies are set to transform operational paradigms. According to a recent report by MarketsandMarkets, the global vision-guided robotics market is expected to grow from $1.5 billion in 2020 to $2.5 billion by 2025, reflecting a robust compound annual growth rate (CAGR) of 10.5%. This growth is fueled by advancements in machine learning and optical technologies that enable robots to perceive and navigate complex environments effectively.

One of the key trends is the integration of artificial intelligence (AI) with VGR systems, allowing for improved decision-making capabilities in dynamic settings. AI-enhanced vision systems can adapt to variations in product orientation and packaging, making them ideal for manufacturing lines. Companies like Siemens are already investing heavily in AI-driven VGR solutions, recognizing their potential to streamline operations and enhance productivity.

**Tip:** To maximize the efficiency of vision-guided robots, ensure that the camera systems are calibrated for different lighting conditions. A consistent setup can lead to better recognition and processing speeds.

Additionally, innovative software solutions are emerging to simplify the programming and deployment of VGR systems. User-friendly platforms enable operators with minimal coding experience to set up and manage robots efficiently. This democratization of technology can significantly reduce the barriers to entry for smaller manufacturers.

**Tip:** Regularly update the vision system software to benefit from the latest optical algorithms and machine learning enhancements for optimal performance.

Vision guided robotics (VGR) has gained significant attention in recent years due to its ability to enhance automation efficiency across various industries. One notable case study is in the automotive sector, where a leading manufacturer integrated VGR technology into their assembly line. By employing advanced cameras and image processing algorithms, robots were able to identify and precisely position components, drastically reducing error rates and assembly time. This technology enabled a seamless collaboration between human workers and machines, allowing for a more flexible and responsive production environment.

Another compelling example can be found in the food industry, where a company utilized vision guided robotics for packaging purposes. The implementation of VGR allowed the robots to recognize different product shapes and sizes, ensuring efficient and accurate packaging. This adaptation not only minimized material waste but also improved the overall throughput of the packaging lines.

As these case studies illustrate, the integration of vision guided robotics showcases significant improvements in operational efficiency, quality control, and adaptability, setting a new standard for automated processes across various sectors.