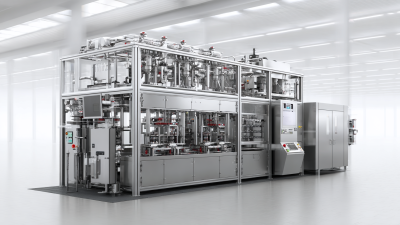

In the rapidly evolving landscape of modern industries, the integration of technology is paving the way for unprecedented levels of automation and efficiency. Central to this transformation is the form fill machine, a device that revolutionizes packaging processes by automating the filling and sealing of products. This innovative equipment not only streamlines operations but also enhances precision and reduces labor costs, making it a vital asset for businesses looking to maintain competitiveness in an increasingly automated world. As industries adapt to consumer demands and market trends, the role of form fill machines will continue to expand, driving improvements in productivity and operational efficiency. This discussion delves into the future of automation, exploring how the capabilities of form fill machines are set to reshape various sectors and contribute to a more efficient industrial ecosystem.

The demand for form fill machines is surging across various industries due to their ability to enhance productivity and ensure consistency in packaging processes. In sectors like food and beverage, pharmaceuticals, and consumer goods, manufacturers are increasingly integrating these automated systems to streamline operations. Form fill machines not only reduce manual labor but also minimize the risk of human error, leading to more accurate measurements and packaging standards. This transition towards automation is driven by the need for faster turnaround times and the growing emphasis on efficiency in manufacturing.

As industries evolve, the versatility of form fill machines becomes more evident. These machines can adapt to different product types and sizes, making them invaluable in today's dynamic market landscape. The rising consumer demand for diverse products packaged efficiently has prompted companies to invest in advanced form fill technologies. This trend is further supported by innovations in machine design, which allow for quicker changeovers and enhanced operational efficiency. Consequently, the integration of form fill machines is not merely a trend, but a strategic move aimed at aligning with the fast-paced demands of modern industrial environments.

The impact of automation on efficiency is evident across various industries, particularly with the integration of form fill machines. These machines streamline the packaging process by automating the filling and sealing of products, thus significantly reducing labor costs and time. For instance, a recent case study in the food and beverage sector highlighted that companies using form fill machines saw a 30% increase in production rates compared to those relying on manual processes. Furthermore, the accuracy of these machines minimizes product waste, leading to better resource utilization.

Statistics reveal that industries adopting automation, like pharmaceuticals and cosmetics, have experienced remarkable efficiency gains. In a report by the International Federation of Robotics, companies reported a 20% reduction in operational costs within the first year of implementing automated filling systems. Additionally, the increased speed of production has allowed businesses to respond swiftly to market demands, ultimately enhancing customer satisfaction. These examples underscore how automation, particularly through form fill machines, is reshaping modern industries by driving efficiency and fostering growth.

The adoption of form fill machines in modern industries marks a significant shift towards enhanced efficiency and substantial cost savings. Automated packaging systems streamline the packaging process, reducing labor costs and minimizing human error, which ultimately leads to a more productive workflow. Companies that implement these systems have reported significant productivity gains, allowing them to increase output without the need for a proportional increase in workforce. This efficiency not only lowers operational costs but also enhances the bottom line, making automation a viable investment for businesses looking to stay competitive.

**Tip:** When considering the implementation of automated packaging systems, assess your production needs thoroughly. This will help you choose the right system that aligns with your output requirements and ensures a smooth transition.

Moreover, automated packaging solutions often feature advanced technology that can monitor quality throughout the packaging process. This continuous oversight helps maintain high standards and reduces waste, resulting in further cost savings. As industries strive for greater sustainability, these systems contribute to minimizing resources used in production and packaging, thus making a positive environmental impact.

**Tip:** Regularly evaluate the performance of your automated systems to identify areas for improvement, ensuring that you maximize your investment and stay ahead in the industry.

| Industry | Cost Savings (%) | Productivity Gains (%) | Reduction in Labor Costs (%) | Return on Investment (ROI, years) |

|---|---|---|---|---|

| Food and Beverage | 15% | 30% | 20% | 2 |

| Pharmaceuticals | 12% | 25% | 15% | 2.5 |

| Cosmetics | 10% | 20% | 12% | 3 |

| Electronics | 18% | 35% | 25% | 1.5 |

| Chemicals | 16% | 28% | 22% | 2.2 |

The realm of manufacturing is undergoing a significant transformation as form fill machines evolve, paving the way for enhanced productivity and efficiency. Future innovations in form fill technology are set to

revolutionize the industry by integrating artificial intelligence and robotics, enabling machines to not only fill but also adjust their operations in real-time based on varying product specifications and market demands. This adaptability ensures that manufacturers can respond swiftly to changes, reducing downtime and minimizing waste.

Advanced sensor technologies and data analytics are also playing a crucial role in this revolution. These innovations enable real-time monitoring and predictive maintenance, allowing businesses to foresee operational challenges before they escalate into costly issues. Furthermore, the incorporation of smart technology facilitates data-driven decision-making, enhancing production planning and resource allocation. As form fill machines become smarter, they promise to streamline processes and elevate operational standards, positioning manufacturers to thrive in an increasingly competitive landscape.

The implementation of automated systems, particularly form fill machines, presents significant challenges across various sectors. According to a report by McKinsey & Company, around 60% of occupations could see at least one-third of their tasks automated, highlighting the urgency for industries to adapt. However, transitioning to automation is often met with resistance due to concerns over job displacement and the initial cost of technology investment. Industries must carefully manage this transition, balancing efficiency gains with workforce re-skilling and integration efforts to mitigate potential socio-economic disruptions.

Furthermore, the technical complexities of integrating new automated systems pose additional hurdles. A study by the International Federation of Robotics indicated that nearly 30% of companies experience difficulties in aligning automated processes with existing workflows. This misalignment can lead to inefficiencies that counteract the intended benefits of automation. To address these challenges, organizations must invest in robust change management strategies that foster collaboration between technology providers and operational teams, ensuring that the rollout of form fill machines and other automated solutions enhances overall productivity without sacrificing employee engagement and expertise.

This bar chart illustrates the potential efficiency improvements in various sectors that implement form fill machines. Automation is becoming increasingly critical for enhancing productivity and reducing operational costs across these industries.