The form fill machine is a vital component in modern packaging. It automates the process of filling products into containers, enhancing efficiency and reducing errors. According to a 2022 market report, the global packaging machinery market is expected to reach $50 billion by 2025, with form fill machines playing a significant role in this growth.

These machines are used across various industries, including food, pharmaceuticals, and cosmetics. A study indicated that 75% of companies reported increased productivity after implementing form fill machines. This technology can handle diverse substances, from liquids to powders, making it versatile. However, operators must ensure these machines are properly calibrated. Misalignment can lead to product waste and inconsistent fill levels.

The gap in understanding machine settings can be concerning. Operators often overlook maintenance, which can result in downtime. Engaging regularly with technical training could improve overall effectiveness. Thus, awareness of both the advantages and the challenges of using a form fill machine is essential. Ensuring optimal operation is a continuous journey.

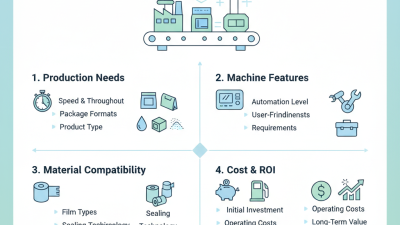

A form fill machine is an innovative device widely used in packaging industries. It simplifies the process of filling containers with various products. These machines operate mainly through two functions: forming the packaging and filling it with the product. Traditional methods of filling are often slow and labor-intensive. In contrast, form fill machines increase efficiency and stability.

The working mechanism of a form fill machine involves several steps. Initially, flat materials are shaped into containers. This may include bags, pouches, or boxes. Once shaped, the machine fills these forms with the desired product, whether it’s liquid, powder, or granular. The process requires precision. Small deviations can lead to inconsistent fills. Operators must oversee the machinery closely, ensuring everything runs smoothly.

Despite their effectiveness, form fill machines have limitations. They may struggle with certain product types, such as those with unique viscosities. Additionally, the setup can be time-consuming. Adjusting for different product sizes often requires technical knowledge. Many users find this aspect challenging, leading to frustration. Constant maintenance is also necessary to keep the machines functioning optimally.

A form fill machine is crucial in various industries, automating the packaging process. Understanding its components helps appreciate its efficiency. Key parts include the hopper, filling mechanism, conveyor system, and control panel.

The hopper holds the product ready for packaging. Its design must accommodate a range of materials. The filling mechanism, often volumetric or gravimetric, determines the precision of each fill. An average filling accuracy of 98% is essential for maintaining product quality. A conveyor system transports packages through the machine, ensuring a smooth workflow. Finally, the control panel allows operators to adjust settings quickly, enhancing operational flexibility.

Despite technological advancements, challenges remain. Operators must regularly calibrate filling mechanisms to prevent inconsistencies. For instance, a report indicated that nearly 30% of packaging errors stem from improper calibration. Continuous training is vital for staff to handle these machines effectively, reducing downtime and boosting productivity. Attention to detail in each component can significantly affect overall efficiency.

A form fill machine is designed to automate the packaging process. It primarily fills containers with products like liquids, powders, or granules. The machine generally consists of several key components: a hopper for holding the product, a filling system, and a sealing mechanism. Each part plays a crucial role in ensuring efficiency and accuracy during the operation.

The operation begins with the hopper feeding the product into the filling system. Sensors detect the container's position, ensuring precise filling. Once the container is in place, the filling mechanism activates. It dispenses the product according to the desired quantity. This process requires calibration to prevent overfilling or underfilling. After filling, the container moves to the sealing area. Here, it is securely closed to maintain freshness and quality.

Despite the efficiency of form fill machines, issues can arise. Sometimes, products clog the filling nozzles. This can lead to inconsistent fill levels. Regular maintenance is essential but often neglected. Human oversight is still necessary for quality control. Observing the operation closely can help identify recurrent issues. Addressing these challenges improves overall productivity.

Form fill machines are versatile tools used in various industries. These machines automate the packaging process, ensuring speed and efficiency. They can handle different products, such as food items, pharmaceuticals, or chemicals. This adaptability makes them crucial in production lines.

In the food industry, form fill machines package snacks, beverages, and frozen goods. They maintain freshness and extend shelf life. However, inconsistency in product measurement can occur, leading to waste. Proper calibration is essential to minimize errors. In pharmaceuticals, these machines ensure accurate dosage, which is critical for patient safety. Yet, mechanical failures can disrupt production schedules and lead to costly downtime.

In the cosmetic sector, form fill machines are used for lotions and creams. These products require precise filling to avoid customer dissatisfaction. Leakages and spills are common challenges that need addressing. Regular maintenance is vital to keep machines running smoothly. Despite their importance, the effectiveness of form fill machines depends greatly on operator training. An untrained operator can hinder the entire process. Each industry has unique challenges that must be considered for successful implementation.

| Application | Industry | Machine Type | Output per Hour | Special Features |

|---|---|---|---|---|

| Packaging of Powders | Food & Beverage | Vertical Form Fill Seal | 250-500 bags | Multi-lane filling |

| Liquid Product Filling | Cosmetics | Automatic Fill and Seal | 500-1000 units | Accurate volume control |

| Granule Packing | Pharmaceuticals | Stand-Up Pouch Filler | 300-700 pouches | User-friendly interface |

| Bulk Liquid Filling | Chemical | Gravity Fillers | 200-400 drums | Easy clean design |

| Snack Packing | Snack Foods | Horizontal Form Fill Seal | 400-800 bags | Flexible film usage |

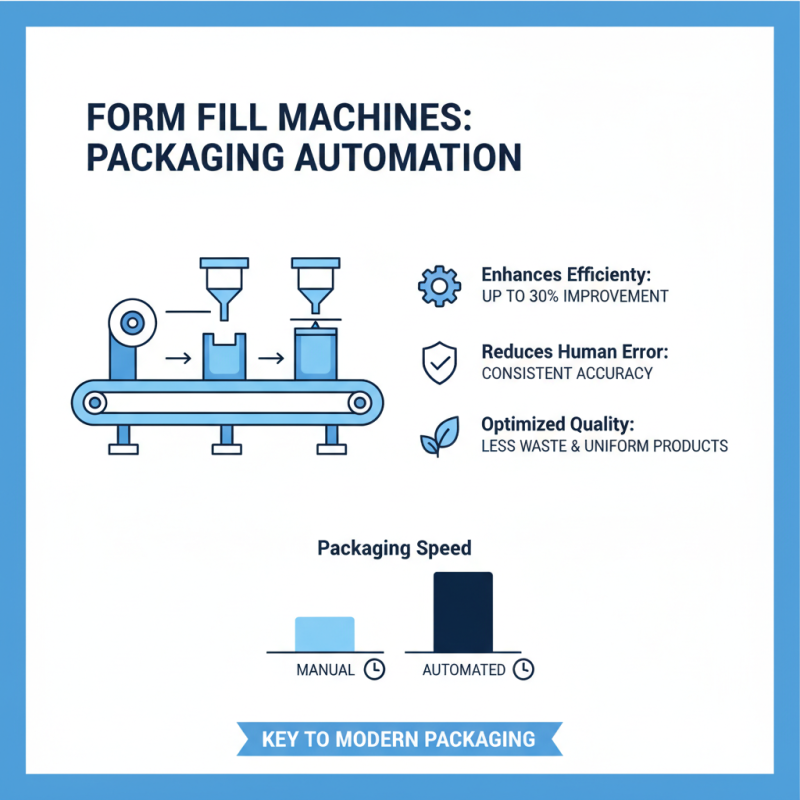

Form fill machines play a crucial role in the packaging industry. They are designed to automate the filling and sealing process. This automation enhances efficiency across various sectors, from food to pharmaceuticals. Data shows that packaging efficiency can improve by up to 30% with the use of these machines. Reducing human error is an additional benefit. Consistent accuracy in filling reduces waste and maintains product quality.

Moreover, form fill machines offer flexibility. They can handle different package sizes and materials. This adaptability is vital in a market that demands quick changes. Industry reports indicate that 70% of manufacturers value machines that can easily switch between products. However, not all machines can meet specific production needs. Some may struggle with complex products. This gap highlights the importance of choosing the right machine for unique requirements.

Additionally, the investment in form fill machines often leads to cost savings. Companies report a decrease in labor costs by 15% after automation. While the initial costs can seem high, the long-term benefits are clear. Improved speed and lower overhead contribute to a better bottom line. Yet, companies must continuously evaluate if their chosen machines align with evolving production needs. Balancing efficiency and adaptability remains a challenge in the dynamic packaging landscape.