In today's fast-paced manufacturing landscape, optimizing operational efficiency is paramount for businesses seeking to enhance productivity and reduce costs. A critical component in this equation is the automated packaging line, which not only streamlines the packing process but also significantly contributes to the overall supply chain effectiveness. As companies strive to meet growing consumer demands while maintaining high standards, understanding how to optimize the automated packaging line has become essential.

Implementing effective strategies can lead to substantial improvements in efficiency, allowing businesses to maximize output and minimize waste. From proper equipment maintenance to staff training, every detail plays a significant role in ensuring that the automated packaging line operates at peak performance. By focusing on the essentials, organizations can unlock their automated packaging line's full potential, thus not only meeting industry standards but also setting new benchmarks for excellence in packaging operations.

This article outlines ten essential tips that will guide manufacturers in refining their automated packaging processes, ensuring they remain competitive and responsive in a rapidly changing market.

Efficiency in packaging lines is crucial for the overall performance of manufacturing operations. An optimized packaging line not only accelerates the production process but also reduces wastage and operational costs. With advancements in technology, companies have the opportunity to implement automation that enhances throughput while maintaining high-quality standards. The significance of streamlining packaging operations cannot be overstated; it has a direct impact on customer satisfaction and the bottom line.

Understanding packaging line efficiency involves recognizing the interplay between various components, such as machinery, workforce, and processes. An efficient line minimizes downtime and maximizes productivity through careful coordination of these elements. By regularly evaluating each stage of the packaging process, organizations can identify bottlenecks and implement targeted improvements. This holistic understanding not only aids in immediate fixes but also creates a foundation for continuous enhancement, encouraging innovation and responsiveness to changing market demands. Ultimately, prioritizing efficiency in packaging lines ensures that businesses remain competitive and adaptive in a rapidly evolving landscape.

| Tip Number | Tip Description | Expected Efficiency Gain (%) | Implementation Difficulty (1-5) |

|---|---|---|---|

| 1 | Conduct regular maintenance on equipment | 15% | 2 |

| 2 | Train staff on operational best practices | 20% | 3 |

| 3 | Implement a real-time monitoring system | 25% | 4 |

| 4 | Optimize workflow layout | 18% | 3 |

| 5 | Use automated quality control systems | 22% | 5 |

| 6 | Establish efficient material handling practices | 15% | 3 |

| 7 | Regularly review and update packing materials | 10% | 2 |

| 8 | Invest in advanced packaging technology | 30% | 5 |

| 9 | Implement a feedback loop for continuous improvement | 12% | 3 |

| 10 | Collaborate with suppliers for better solutions | 14% | 2 |

Measuring the performance of your automated packaging line is essential for optimizing its efficiency and effectiveness. Key metrics such as throughput, cycle time, and overall equipment effectiveness (OEE) play a crucial role in identifying bottlenecks and areas for improvement. Tracking these metrics regularly enables managers to gain insights into how well the packaging line operates and where adjustments can lead to enhanced productivity.

To effectively optimize efficiency, one must consider implementing continuous training for staff on the latest technologies and systems utilized in packaging. Well-trained employees can identify issues swiftly, minimizing downtime and ensuring smooth operations. Additionally, regularly scheduled maintenance checks are vital; they can prevent unexpected breakdowns and prolong the life of your machinery. Another critical tip is to analyze the data collected from performance metrics and look for trends that indicate long-term improvements or potential concerns that need addressing.

Investing in automation technologies, such as smart sensors or data analytics software, can provide real-time insights into production processes. This data can facilitate quick decision-making and enhance the ability to scale operations as needed, ensuring that the packaging line remains competitive and efficient. By focusing on these key metrics and tips, businesses can significantly boost the performance of their automated packaging lines.

Maintaining optimal performance in an automated packaging line is paramount to achieving efficiency and minimizing downtime. Regular equipment maintenance is essential to ensure that each component operates at peak efficiency. A proactive maintenance strategy includes creating a comprehensive schedule for inspections and preventive repairs. This not only helps identify potential issues before they escalate into costly breakdowns but also extends the lifespan of the equipment. Regularly reviewing equipment performance metrics and conducting routine calibration can further enhance reliability, ensuring that the entire line functions smoothly.

In addition to scheduled maintenance, staff training plays a critical role in equipment upkeep. Workers should be well-versed in operational protocols and safety procedures, which helps prevent accidental damages and ensures that any minor issues are swiftly addressed. Implementing a culture of accountability among team members fosters responsibility for equipment care. Moreover, utilizing technology such as predictive maintenance tools can provide valuable insights into equipment health, allowing for data-driven decisions to optimize performance. By prioritizing maintenance and investing in personnel training, businesses can achieve a more efficient automated packaging line, ultimately driving productivity and reducing operational costs.

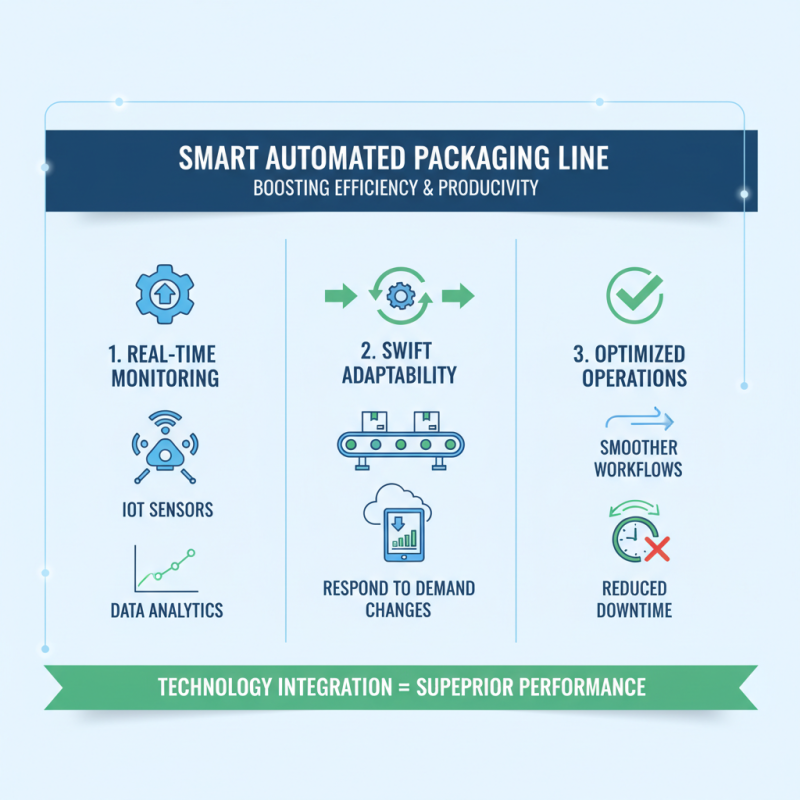

In today's fast-paced manufacturing environment, integrating technology into your automated packaging line is crucial for enhancing efficiency and productivity. Modern automation solutions, such as IoT sensors and advanced data analytics, enable real-time monitoring and adjustments, allowing businesses to respond swiftly to changes in demand or operational conditions. By utilizing these technologies, packaging lines can achieve smoother workflows and reduce downtime significantly.

One essential tip for optimizing efficiency is to implement predictive maintenance strategies using smart sensors. These sensors can monitor equipment performance and predict potential failures before they occur, minimizing unexpected halts in production. Another important aspect is to leverage flexible automation systems, which can adapt to different packaging formats without extensive reconfiguration. This adaptability not only streamlines operations but also reduces labor costs and improves response times to market fluctuations.

Additionally, integrating machine learning algorithms can enhance quality control processes. These algorithms can analyze data from past production runs to identify patterns and anomalies, ensuring that products meet quality standards consistently. By focusing on these technological integrations, manufacturers can optimize their packaging lines, achieving higher efficiency and better overall performance.

Training staff effectively is crucial for the optimal operation of packaging systems in an automated packaging line. A well-structured training program ensures that operators understand not only how to use the equipment but also the underlying principles of automation technology. This knowledge empowers staff to spot potential issues before they escalate, leading to minimized downtime and enhanced productivity. Incorporating hands-on training sessions along with theoretical knowledge allows employees to become proficient in both troubleshooting and preventative maintenance tasks.

Moreover, ongoing training is paramount in keeping pace with technological advancements in packaging systems. Regular workshops and refresher courses enable staff to stay updated on new features and best practices. Encouraging a culture of continuous learning fosters employee engagement and improves overall efficiency. By valuing education in the workplace, companies create a team that is more adaptable to changes, ultimately leading to a more streamlined packaging process and higher output quality.

The integration of training into the daily workflow not only enhances performance but can also contribute to employee satisfaction and retention, creating a more stable and experienced workforce.