Choosing the right VFFS packaging solution is crucial for your business’s success. According to Jane Smith, a leading expert in the VFFS packaging industry, “The right packaging can significantly enhance product appeal.” This quote highlights the importance of selecting the best packaging method for your products.

When exploring VFFS packaging options, consider aspects like product type and volume. Many companies struggle to identify their specific needs. A vague understanding of your requirements can lead to poor choices. Not all VFFS solutions fit every product. Each has unique features that may or may not align with your business goals.

Effective VFFS packaging should protect your product and make it attractive. Many businesses overlook this balance. Opting for cheaper solutions might save money initially but could result in higher costs later. An investment in quality packaging pays off in customer satisfaction and brand loyalty. As we delve into essential tips, keep your objectives in focus. Remember, the right VFFS packaging is not just about function; it’s about finding a solution that resonates with your brand.

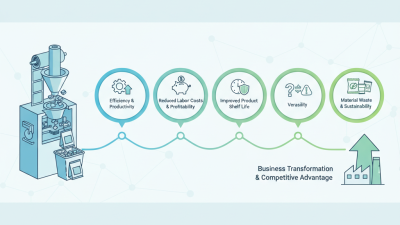

Vertical Form Fill Seal (VFFS) packaging technology has revolutionized how products are packed. It involves forming a bag from a flat roll of film, filling it with product, and sealing it in one continuous process. This method is efficient, reducing labor costs significantly. According to industry reports, 65% of manufacturers are shifting to VFFS due to its speed and flexibility.

One notable aspect of VFFS is its adaptability. It can handle various products, from granules to liquids. This versatility can lead to challenges, though. For instance, some machines may struggle with sticky products. A survey showed that 30% of users experienced difficulties with specific product types. Selecting the right machine for your product is crucial. An improper choice can lead to downtime and increased operational costs.

Moreover, VFFS machinery is evolving. Many now include advanced features like automated adjustments and real-time monitoring. However, businesses may overlook the importance of maintenance. Neglecting service can lead to unexpected failures. Reports indicate that unplanned downtime can cost companies about $250,000 annually. Investing in a reliable service program is beneficial for long-term productivity.

This chart illustrates the key factors businesses consider when selecting a Vertical Form Fill Seal (VFFS) packaging solution. The data reflects their relative importance based on industry research.

When selecting a vertical form-fill-seal (VFFS) packaging machine, several key factors come into play. One of the most significant is the type of product being packaged. Granules, powders, or liquids each demand different handling features. Consider the flow characteristics of your product. A machine suitable for free-flowing items may not work for sticky or chunky products. Assess your product sizes too. They can influence the bag dimensions and sealing requirements.

Another crucial factor is production speed. Machines vary in output rates. Think about your production schedule. Can the chosen machine keep pace? You may need a higher-performing machine for large volumes. Additionally, ease of operation and maintenance is vital. A machine that requires constant attention can disrupt workflow. Look for user-friendly controls and efficient cleaning mechanisms.

It's important to note the material compatibility. Different films and materials suit different packaging needs. Ensure your choice aligns with shelf life and product preservation. Lastly, budget is always a concern. Investing in a quality machine can be costly. However, consider the long-term benefits of efficiency and durability. Always reflect on these points during your selection process to avoid potential pitfalls later on.

When choosing a Vertical Form Fill Seal (VFFS) packaging solution, material compatibility is crucial. The right materials ensure product safety and maintain freshness. According to a 2022 industry report, 30% of packaging failures stem from material incompatibility. It is vital to evaluate which materials best suit your products, given this statistic.

Consider the nature of your product. Are you dealing with dry goods or liquids? Flexibility and durability are paramount. Certain films resist moisture better, which can prevent spoilage. For instance, a study highlighted that using high-barrier films reduced moisture permeability by 70%. However, while these materials are effective, they can be more expensive. Cost versus benefit analysis is essential and should be revisited.

Also, check for compliance with food safety regulations. Not all materials meet industry standards, posing risks to consumers. Research indicates that 15% of packaging fails regulatory checks due to improper material use. Reflecting on these insights can highlight the importance of aligning your packaging choices with material properties, even if it leads to a challenging decision-making process.

Analyzing production speed requirements is crucial when selecting a Vertical Form-Fill-Seal (VFFS) packaging solution. Different products may demand varying speeds. Some items can be packaged quickly, while others need a slower, more careful approach. It's essential to assess the specific needs of your product to find the right match.

Consider your production line's capacity. A high-speed VFFS machine may seem appealing. However, if your product requires special handling or precise filling, speed could compromise quality. Reflect on how fast you need to package your products. Are you prioritizing volume over quality? This question is vital for the decision-making process.

Another factor to examine is the flexibility of the machine. Will it adapt to changes in speed requirements? Sometimes, a slower speed can yield better accuracy, reducing waste and ensuring consistency. It's worth pondering whether sacrificing speed could result in more efficient production in the long run. Balancing quality and speed can lead to better overall performance.

| Tip Number | Consideration | Production Speed Requirement (units/min) | Recommended Machine Speed (units/min) | Notes |

|---|---|---|---|---|

| 1 | Product Type | 30 | 40 | Use lightweight films for non-heavy products |

| 2 | Bag Size | 25 | 35 | Consider variability in package size for adjustment |

| 3 | Material Compatibility | 20 | 30 | Ensure materials are matched to the product |

| 4 | Automation Level | 40 | 60 | Consider how much manual work is acceptable |

| 5 | Line Efficiency | 35 | 50 | Optimize layout for higher throughput |

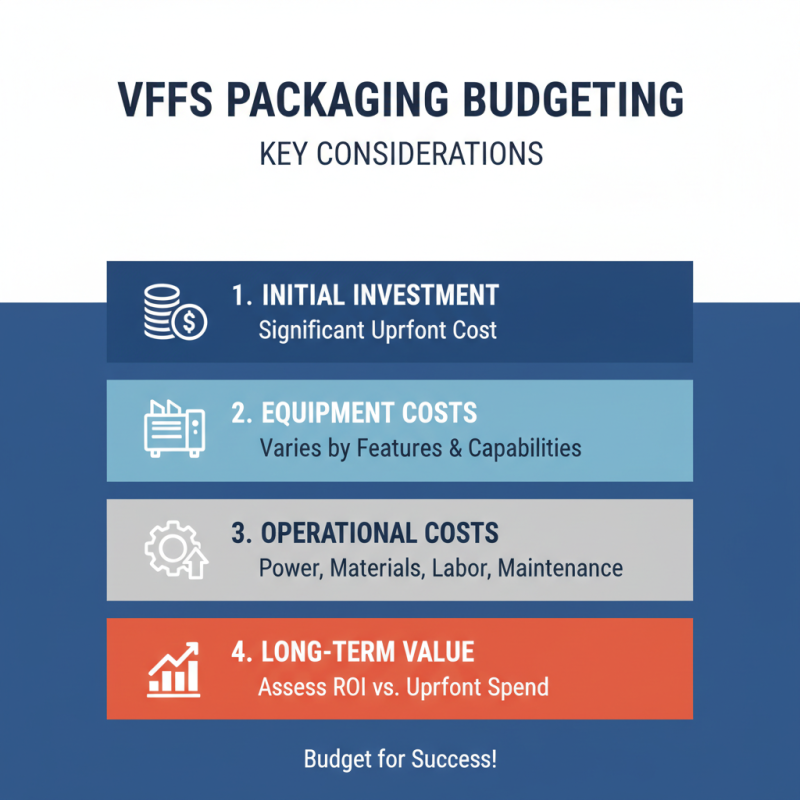

When considering a vertical form fill seal (VFFS) packaging solution, budgeting plays a crucial role. The initial investment can be significant. Equipment costs vary widely based on features and capabilities. It is important to assess your production needs. A budget that accommodates both equipment and operational costs is essential. Review the long-term value versus upfront expenses.

Operational costs may include maintenance, labor, and materials. These factors can change over time. It's wise to include a cushion for unexpected expenses. Research different suppliers and compare quotes. An economical choice today might not provide the same value in a few years. Always consider scalability in your budget. As production grows, will your current VFFS solution meet your needs?

Investing in quality can prevent issues down the line. Cheap solutions may lead to frequent breakdowns. A well-planned budget reflects future needs. It’s essential to remain flexible in your financial planning. Adjustments may be needed as technology evolves or market demands shift. Balancing cost and quality is a challenge that requires careful thought.