As businesses increasingly seek to optimize their operations, the demand for automation technologies, particularly packaging robots, continues to rise. According to a report by MarketsandMarkets, the packaging robots market is projected to reach $8.83 billion by 2026, growing at a CAGR of 12.4% from 2021 to 2026. This surge indicates that more companies are recognizing the potential of packaging robots to enhance efficiency, reduce labor costs, and improve product consistency.

Selecting the right packaging robots is crucial for businesses seeking to stay competitive in today's fast-paced market. With a plethora of options available, ranging from robotic arms to autonomous mobile robots, understanding the specific needs of your operation is essential. A 2020 study by the International Federation of Robotics (IFR) highlighted that automation could reduce packaging costs by up to 30%, showcasing the financial benefits of investing in the right technology. Businesses must assess their production requirements, space constraints, and workforce capabilities to ensure they choose packaging robots that align with their objectives and drive long-term success.

When selecting the right packaging robots for your business, it's crucial to first identify your specific

packaging needs. Understanding the volume of products you handle regularly, as well as their dimensions and weight, can significantly influence your decision.

Assessing the complexity of your packaging processes is essential; for instance, do you need a robot for basic tasks like box packing or more sophisticated

functions such as labeling and sorting?

One tip is to evaluate the scalability of the robot. Your business may grow, and the robot should be able

to adapt to increased production requirements. Another consideration is the compatibility of the robot with your existing production line. Systems that seamlessly

integrate with current technologies will save you time and potential costs associated with adjustments. Lastly, think about the versatility of the robot—ideally, it should handle various packaging types and formats to maximize

your investment and flexibility in operations.

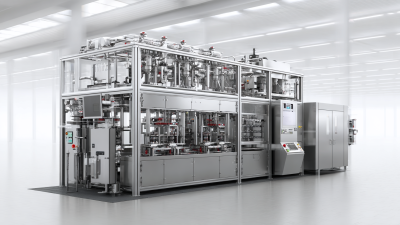

When assessing packaging robots for your business, it's crucial to consider the specific type of robot that fits your product range and production needs. Different industries, such as pharmaceuticals, have unique requirements. For instance, the blister packaging machine segment in the pharmaceutical market was valued at $520 million in 2022 and is projected to reach $840 million by 2030, reflecting a compound annual growth rate (CAGR) of 7.3% from 2024 to 2030. This strong growth indicates a rising demand for efficient and reliable packaging solutions.

Furthermore, the suitability of various packaging robots can depend on factors like speed, flexibility, and the ability to handle diverse packaging formats. As more companies look to improve their production efficiency, robots that can seamlessly integrate into existing workflows and adapt to multiple product types will be increasingly valuable. Evaluating your business's current and future packaging needs in light of these trends will help you select the most appropriate robotic solution.

Investing in packaging automation can lead to significant cost savings and efficiency improvements, but it's crucial to assess the long-term cost-effectiveness of such a decision. When evaluating the potential return on investment (ROI) from packaging robots, businesses should consider both direct savings and indirect benefits. Direct savings often come from reducing labor costs and minimizing material waste, while indirect benefits may include increased production rates and improved product quality, which can enhance customer satisfaction and retention.

To accurately gauge the cost-effectiveness of packaging automation, companies should conduct a thorough analysis of their current processes, identifying bottlenecks and inefficiencies. This assessment can help quantify potential savings and establish a clear baseline for measuring improvements after automation. Additionally, it’s beneficial to calculate the total cost of ownership (TCO) of the robotic systems, which should include initial investment, maintenance, and operational costs. By comparing these figures against projected gains in productivity and revenue, businesses can make informed decisions about which packaging robots will deliver the best value and align with their strategic goals.

| Tip Number | Tip Description | Cost Impact (%) | ROI Period (Months) | Suitability Score (1-10) |

|---|---|---|---|---|

| 1 | Analyze Current Packaging Needs | 15% | 6 | 9 |

| 2 | Evaluate Potential Robots' Flexibility | 20% | 8 | 8 |

| 3 | Consider Maintenance Costs | 10% | 12 | 7 |

| 4 | Assess Scalability Options | 5% | 9 | 9 |

| 5 | Check Industry Standards Compliance | 8% | 7 | 10 |

| 6 | Consult with Packaging Experts | 12% | 5 | 8 |

| 7 | Evaluate Technology Integration | 18% | 10 | 9 |

| 8 | Consider Total Cost of Ownership | 14% | 11 | 8 |

| 9 | Assess Training and Support Options | 9% | 4 | 7 |

| 10 | Calculate Potential Productivity Gains | 22% | 8 | 10 |

When evaluating packaging robots, it’s crucial to consider how they will integrate with your existing production lines. A successful integration process begins with a thorough analysis of your current operations, including machinery, workflow, and product types. Assessing these elements will help identify any compatibility issues and highlight areas where the new robotic systems can enhance efficiency. Understanding these integration requirements will also facilitate a smoother transition, reducing downtime and ensuring that the packaging process aligns seamlessly with current production schedules.

Moreover, it’s essential to collaborate closely with your automation suppliers during the selection process. They can offer valuable insights into the technical specifications and capabilities of various robotic solutions. Engage in discussions about your existing equipment, production goals, and potential bottlenecks. This partnership can lead to tailored solutions that not only meet your packaging needs but also improve overall productivity. By prioritizing integration from the beginning, you position your business for long-term success and scalability as operational demands evolve.

When selecting the right packaging robot supplier for your business, it’s crucial to assess a few key criteria to ensure reliability and quality. A recent industry report by MarketsandMarkets suggests that the global packaging robots market is projected to grow from $4.6 billion in 2023 to $8.9 billion by 2028, underscoring the significance of making informed decisions. One fundamental tip is to investigate the vendor's experience—companies with a proven track record are more likely to deliver solutions that meet industry standards.

Another critical factor is after-sales support. According to a survey conducted by Robotics Business Review, over 70% of businesses highlighted the importance of continuous support and maintenance services when choosing automation vendors. A supplier that offers comprehensive training and responsive technical support can help mitigate downtime and enhance operational efficiency.

Additionally, evaluate the supplier’s technology offerings. Look for vendors that provide flexible and scalable solutions that can adapt to your evolving business needs. As highlighted in the 2022 Packaging Automation Report, companies integrated with adaptable technology saw up to a 30% increase in productivity. Engaging with suppliers that stay ahead of technological advancements is essential for staying competitive in a rapidly evolving market.