In today's competitive market, selecting the right packaging machinery is crucial for the success and efficiency of any business. As industry expert Jonathan Green, a leading consultant in the packaging sector, eloquently states, "The right packaging machinery can not only streamline production but also enhance product appeal, ultimately driving sales." This insight emphasizes the importance of making informed decisions when investing in packaging systems.

With advancements in technology and evolving consumer demands, the landscape of packaging machinery continues to shift. Businesses are faced with an array of options, each promising to deliver unique benefits. However, navigating through these choices requires a thorough understanding of one's specific needs. The effectiveness of packaging machinery can greatly influence operational costs, production speed, and overall product quality—factors that are essential for maintaining a competitive edge.

As we delve into the ten essential tips for choosing the right packaging machinery for your business, the focus will be on aligning these tips with the strategic goals of your operations. From assessing production volumes to considering automation capabilities, this guide will equip you with the knowledge needed to make sound investments in packaging machinery that can support your business's growth and efficiency.

When selecting packaging machinery for your business, it is crucial to first identify your specific packaging needs and requirements. Assess the types of products you are packaging, their dimensions, and the quantity you expect to produce daily. This foundational understanding helps in determining the right machinery that will efficiently meet your production goals while ensuring product integrity.

One essential tip is to evaluate the speed and capacity of the machinery. Consider how much product you need to package per hour and whether the machine can keep up with your production line demands without sacrificing quality. Another important factor is flexibility; look for machinery that can adapt to different product sizes and types, which is beneficial if you plan to expand your product range in the future.

Additionally, pay attention to the level of automation required. Automated packaging machinery can significantly enhance productivity and reduce labor costs. However, consider the training and maintenance required for such equipment, as well as your current workforce’s skill level. By prioritizing these aspects, you can ensure that your choice of packaging machinery aligns perfectly with your business strategy and operational capabilities.

When evaluating different types of packaging machinery for your business, it's crucial to align your choice with production requirements, product types, and packaging styles. Various machinery types—such as filling machines, labeling machines, and vacuum sealers—each serve specific purposes and have their advantages. According to a report by Smithers Pira, the global market for packaging machinery is expected to reach $50 billion by 2025, emphasizing the need for businesses to make informed decisions to remain competitive.

Tip: Assess your production volume and choose machinery that can accommodate current and future demands. For instance, high-speed filling machines are ideal for businesses with large production runs, whereas semi-automatic machines may suffice for smaller operations. Additionally, consider the versatility of the machinery; equipment that can handle different packaging formats can save you from needing multiple machines down the line.

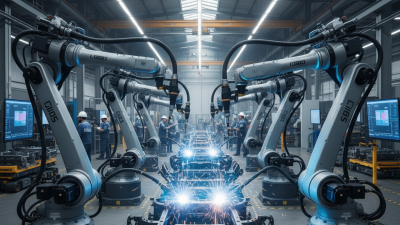

Another essential tip is to evaluate the technology and automation level of the machinery. Automated packaging systems offer improved efficiency and reduced labor costs, with a recent industry study indicating that automation can enhance production by up to 30%. However, the right balance must be struck between automation and flexibility, ensuring that the machinery can adjust to varying product sizes and types without extensive downtime. By carefully considering these factors, businesses can select packaging machinery that best suits their operational needs.

When selecting packaging machinery, one of the most critical factors to consider is the level of automation. The right degree of automation can significantly enhance the efficiency of your packaging process, reducing labor costs and minimizing human error. Machines that integrate automated features—such as automatic loading and unloading, as well as real-time monitoring systems—can streamline operations and improve output consistency. Assessing your production needs and expected workload is crucial in determining the suitable automation level; for instance, high-volume production lines might benefit from fully automated systems, while smaller operations could explore semi-automated alternatives.

Cost considerations also play a vital role in your decision-making process. While fully automated machinery may come with a higher initial investment, the potential long-term savings in labor costs, reduced waste, and increased production capacity often justify the expense. It is essential to conduct a thorough cost-benefit analysis, comparing the operational efficiencies gained through automation against the upfront costs and ongoing maintenance expenses. By understanding these dynamics, businesses can make informed decisions that align with their financial goals and operational requirements, securing a competitive edge in their respective markets.

When choosing packaging machinery for your business, understanding machine compatibility is crucial for ensuring seamless integration into your existing production line. Each piece of machinery needs to work harmoniously with other equipment and processes to minimize downtime and enhance productivity. Compatibility extends beyond mere physical dimensions; it involves evaluating the technology, operational capabilities, and software interfaces that your machines utilize. By prioritizing compatibility, you can avoid costly retrofitting or operational delays that could arise from integrating incompatible systems.

Moreover, assessing machine compatibility enables you to future-proof your operations. As your business evolves, you may require additional machinery or upgrades to meet rising demands. Selecting packaging equipment that aligns with your current systems can facilitate easier expansions and enhancements. Additionally, this foresight aids in staff training, as employees can develop proficiency with compatible machines rather than juggling multiple technologies. Ultimately, a thoughtful approach to machine compatibility not only streamlines your production processes but also contributes to the longevity and efficiency of your packaging operations.

| Tip No. | Tip Description | Important Factor |

|---|---|---|

| 1 | Assess Your Production Needs | Production Volume |

| 2 | Understand Packaging Types | Material Compatibility |

| 3 | Evaluate Automation Levels | Labor Costs |

| 4 | Consider Space Requirements | Floor Plan |

| 5 | Check Compatibility of Existing Equipment | Interoperability |

| 6 | Research Maintenance Requirements | Downtime Impact |

| 7 | Evaluate Cost vs. Benefit | ROI Analysis |

| 8 | Seek Expert Consultation | Industry Knowledge |

| 9 | Plan for Future Scalability | Growth Projections |

| 10 | Test Machinery Before Purchase | Performance Metrics |

When selecting packaging machinery for your business, prioritizing supplier support and maintenance services is crucial for ensuring long-term operational efficiency. A recent report from the Packaging Machinery Manufacturers Institute (PMMI) highlights that nearly 60% of packaging machinery failures stem from inadequate maintenance. This statistic underscores the importance of having a reliable supplier who not only sells equipment but also offers robust support services. A supplier that provides routine maintenance checks, access to spare parts, and expert troubleshooting can significantly reduce downtime and associated costs, ultimately enhancing productivity.

Furthermore, businesses should consider the availability of training for their staff. According to a study by McKinsey, companies that invest in proper training and ongoing support see a 25% increase in equipment efficiency. When a machinery supplier offers comprehensive training programs alongside maintenance services, it equips your team with the knowledge to operate machines effectively, reducing the likelihood of operational errors that may lead to costly repairs. A partnership with a supplier that prioritizes these services can make a marked difference in your production processes, ensuring your investment in packaging machinery pays off in the long run.