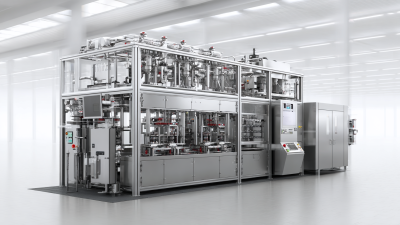

In the fast-paced world of packaging, efficiency is a paramount goal for manufacturers aiming to meet increasing consumer demands while minimizing costs. This pursuit has led to the widespread adoption of advanced technologies, particularly the horizontal form fill seal machine, which streamlines the packaging process by simultaneously forming pouches, filling them, and sealing them in a continuous operation. These machines not only enhance production speed but also improve product integrity and reduce material waste. As the packaging industry evolves, understanding the key features and benefits of horizontal form fill seal machines becomes crucial for businesses looking to remain competitive. In this guide, we will explore effective strategies to unlock greater efficiency in packaging operations, leveraging insights into the latest advancements and best practices surrounding these innovative machines.

Optimizing packaging processes is essential for businesses aiming to enhance productivity and reduce costs. Horizontal Form Fill Seal (HFFS) technology has emerged as a game-changer in various industries, enabling manufacturers to achieve high-speed packaging while maintaining product integrity. According to a recent report by MarketsandMarkets, the global market for HFFS machines is projected to reach $6.89 billion by 2026, driven by the rising demand for efficient and innovative packaging solutions. This technology allows for the automated packaging of products into pouches or bags, significantly improving throughput and reducing labor costs.

Tip: To maximize the efficiency of HFFS machines, it’s crucial to continuously monitor machine performance and conduct regular maintenance. This can lead to a decrease in downtime and ensure that packaging operations run smoothly.

Furthermore, integrating smart technology into HFFS operations can offer real-time data analytics, allowing manufacturers to optimize their packaging lines further. A report by Smithers Pira indicated that smart packaging solutions could enhance operational efficiency by 15-20%. By implementing advanced sensors and data management systems, companies can track production metrics, identify bottlenecks, and streamline their processes effectively.

Tip: Implementing feedback loops where operators can report inefficiencies can help teams address issues proactively and refine their packaging strategies.

Horizontal Form Fill Seal (HFFS) machines have revolutionized the packaging industry by significantly enhancing efficiency and productivity. Reports from the Freedonia Group indicate that the global market for HFFS equipment is projected to reach $4.5 billion by 2026, driven by the increasing demand for ready-to-eat meals and convenient packaging. These machines streamline the packaging process by forming bags from a roll of film, filling them with product, and sealing them, all in one continuous operation. This integrated approach reduces labor costs and minimizes material waste, enabling manufacturers to achieve higher output rates with lower operational expenditures.

One of the key benefits of implementing HFFS machines is their adaptability to a wide range of products. Advanced models are capable of handling both solid and liquid goods, catering to multiple industries such as food, pharmaceuticals, and personal care. According to a recent study by Research and Markets, the food packaging segment is expected to dominate the HFFS market, accounting for over 55% of total revenue by 2025. Furthermore, the ability to customize packaging sizes and styles enhances product appeal, leading to improved consumer engagement and brand loyalty. With these advantages, HFFS machines represent a critical investment for businesses aiming to optimize their packaging processes while staying competitive in the evolving market landscape.

When selecting packaging equipment, especially Horizontal Form Fill Seal (HFFS) machines, several essential factors should be taken into account to ensure optimal efficiency and productivity. Firstly, the type of product being packaged plays a crucial role in equipment selection. Different products require specific packaging materials and seal methods, which can influence the performance of HFFS machines. For instance, liquid products may need machinery that provides additional sealing integrity to avoid leaks, while dry products might prioritize speed and efficiency in the sealing process.

Another critical factor to consider is the production capacity and speed of the machine. Evaluating your production goals will assist in determining the required output per hour and the machine's ability to meet those targets without compromising quality. Additionally, ease of use and maintenance should not be overlooked; selecting machines that offer user-friendly interfaces and easy access for cleaning and repairs can significantly reduce downtime, thus enhancing overall operational efficiency. Integrating these considerations into your decision-making process will ultimately lead to a more tailored and effective packaging solution.

| Feature | Description | Benefits |

|---|---|---|

| Speed | Machines can fill and seal packages at high rates. | Increased production efficiency and reduced time per package. |

| Flexibility | Able to handle various package sizes and materials. | Adaptable to changing product lines and market demands. |

| Ease of Operation | User-friendly interfaces and automated processes. | Reduced training time and human error. |

| Maintenance | Requires regular upkeep to ensure optimal function. | Prevents breakdowns and prolongs machinery lifespan. |

| Cost | Initial investment varies by machine capability. | Long-term savings on labor and inefficiencies. |

| Sustainability | Ability to use eco-friendly materials and minimize waste. | Aligns with corporate responsibility goals and consumer preferences. |

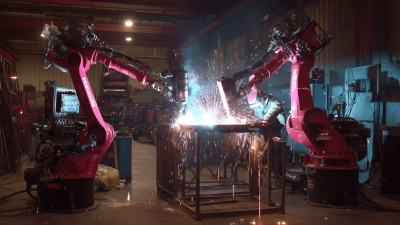

Horizontal Form Fill Seal (HFFS) machines have transformed packaging processes across various industries, driving efficiency and reducing operational costs. One notable case study is in the food sector, where a prominent snack manufacturer implemented HFFS technology to streamline their packaging line. By switching to automated HFFS solutions, they increased their production speed by 30% while maintaining product freshness and quality. The integration of advanced sealing systems also minimized material waste, resulting in significant cost savings and enhanced sustainability practices.

Horizontal Form Fill Seal (HFFS) machines have transformed packaging processes across various industries, driving efficiency and reducing operational costs. One notable case study is in the food sector, where a prominent snack manufacturer implemented HFFS technology to streamline their packaging line. By switching to automated HFFS solutions, they increased their production speed by 30% while maintaining product freshness and quality. The integration of advanced sealing systems also minimized material waste, resulting in significant cost savings and enhanced sustainability practices.

In the pharmaceutical industry, another case illustrates the versatility of HFFS machines. A leading pharmaceutical company adopted HFFS for packaging their over-the-counter medications, benefiting from the machines’ ability to handle a variety of pouch sizes and configurations. This flexibility enabled the company to quickly adjust their production lines for different products without extensive downtime. Additionally, the secure packaging format ensured compliance with stringent regulatory standards while improving shelf appeal and consumer trust. These real-world applications highlight how HFFS technology is driving innovation and efficiency across diverse sectors.

The packaging industry is experiencing a transformative phase as innovations in technology and machinery reshape how products are packaged. One notable advancement is the integration of Horizontal Form Fill Seal (HFFS) machines, which streamline the packaging process by combining forming, filling, and sealing into one continuous operation. This not only reduces labor costs but also enhances operational efficiency, allowing manufacturers to respond quickly to market demands. As companies seek to improve their sustainability, many HFFS machines are now designed to accommodate eco-friendly materials, reflecting a growing emphasis on both efficiency and environmental responsibility.

Looking ahead, several trends are poised to define the future of packaging. Automation and smart technology are becoming integral, with smart packaging solutions that not only improve efficiency but also provide valuable data about products in transit. These innovations can lead to enhanced inventory management and reduced waste. Additionally, customization is on the rise as brands aim to differentiate themselves in a crowded marketplace. As consumer preferences continue to evolve, the ability to adapt packaging solutions quickly will be crucial. The synergy of efficiency and innovation in packaging will ultimately drive success in an increasingly competitive landscape.