When it comes to choosing the right form fill machine for your business, things can get complicated. James Thompson, a packaging industry expert, once remarked, “Selecting the right equipment can make or break your efficiency.” This insight echoes the importance of making well-informed decisions.

The right form fill machine should align with your specific production needs. It should handle your products efficiently, while also fitting within your budget. Different machines offer varied features, which may overwhelm you at first glance. Examining specifications can feel daunting, but it is vital for success.

Moreover, you should reflect on your long-term goals. Choosing a form fill machine requires not just evaluating current needs. Consider future production increases or expansions. The equipment should be scalable and adaptable. This decision impacts your operational efficiency, so weigh your options carefully.

When selecting a form fill machine, understanding the different types is crucial. There are several categories of machines available. Each has specific features suited for various applications. For instance, vertical form fill machines are ideal for bags containing solid products. They provide efficient packaging for snacks, grains, and powders. Their compact design is a significant advantage for smaller spaces in production lines.

On the other hand, horizontal form fill machines offer versatility. They are better for larger or bulk items. These machines can handle a variety of materials and sizes. However, finding the perfect fit for your product can be challenging. You need to consider the machine's speed and layout compatibility. Some businesses might struggle with the transition between different products. Testing is often necessary to avoid wastage.

Moreover, the operation of these machines can be complex. Users may experience a learning curve. It’s essential to evaluate your production requirements and budget. Overspending on features that won’t be used is a common pitfall. Balancing cost and functionality requires careful thought. Regular maintenance is also key to longevity. Ignoring this could lead to costly downtimes. It’s a process of trial and error to find the right one that truly meets your needs.

When choosing a form fill machine, it's crucial to assess your business's specific filling requirements. Consider the types of products you fill. Are they liquids, powders, or granules? Each product type may require different machinery. For liquids, a pump system might be essential. For powders, a volumetric or auger filler could be more suitable. Understanding product characteristics is vital.

Next, evaluate your production volume. High-volume operations may benefit from automated systems. However, smaller businesses could manage with semi-automated machines. Reflect on your growth projections. If you expect an increase in sales, opting for a machine with scalability options could be wise. It’s worth noting that sometimes, machines don’t perform as expected during peak times. Regular maintenance is necessary to ensure reliability.

Also, consider the skill level of your staff. Complex machines may require specialized training. This can be a hidden cost and should not be overlooked. Mistakes during setup can lead to inefficiencies or waste. Hence, a balance between ease of use and capability is essential. Investing in the right machine can significantly impact your bottom line.

Choosing the right form fill machine is crucial for any business involved in packaging. Key features and specifications can greatly affect your efficiency and output. First, consider the machine's speed. Some machines operate at a slower pace but offer precision, while others prioritize volume. Assess what aligns best with your production goals.

Next, look into the machine's compatibility with various materials. This includes different types of films and pouches. Some machines may not handle all materials well, which could lead to waste. Take the time to test materials before settling on a machine. Additionally, think about the machine's size. A compact size may save space but could limit your output capacity. Reflect on your business's growth potential when making this choice.

Maintenance requirements are another critical aspect. Some machines require extensive upkeep, while others are more user-friendly. It’s worth investigating how often parts need replacement. A machine that seems ideal might demand more attention than you have. In the end, balance your needs with the features available. Every choice comes with its trade-offs, and understanding them is key.

| Feature | Description | Importance |

|---|---|---|

| Machine Speed | The rate at which the machine can fill and seal products. | Critical for high-volume production. |

| Product Compatibility | Types of products that can be handled (liquids, powders, granules). | Ensures the machine meets specific needs. |

| Fill Volume Range | The range of different fill volumes the machine can handle. | Flexibility for various product sizes. |

| Ease of Operation | How user-friendly and intuitive the machine controls are. | Reduces labor training time. |

| Maintenance Requirements | Frequency and ease of required maintenance tasks. | Essential for long-term cost management. |

| Size and Footprint | Physical dimensions of the machine and required workspace. | Important for facility layout and space utilization. |

| Budget | Total cost of the machine including installation and setup. | Critical for financial feasibility. |

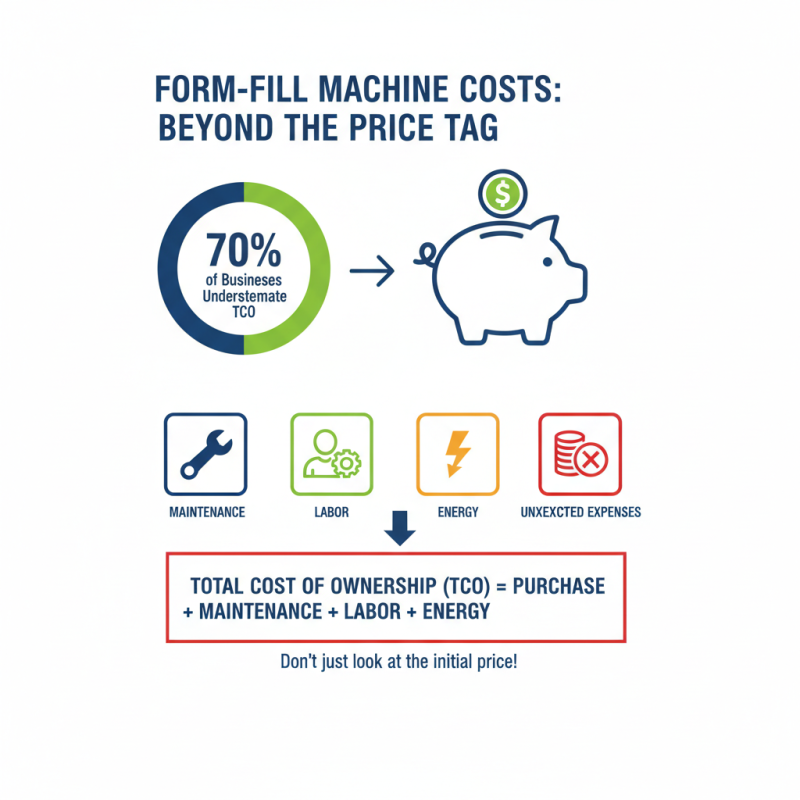

When evaluating form fill machines, budget constraints are critical. According to a recent industry report, 70% of businesses underestimate total cost of ownership. Initial purchase price is just one aspect. Maintenance, labor, and energy costs must also be considered. Neglecting these factors can lead to unexpected expenses down the line.

The total cost of ownership varies significantly across different machines. The average operational cost can reach 20% of the initial investment annually. This figure emphasizes the need for a comprehensive analysis. For instance, cheaper options may require more frequent repairs and higher downtime, which could erode potential savings.

Additionally, organizations should assess their production volume. Equipment for lower volume operations might be less costly but can limit scalability. It’s crucial to align equipment choice with future growth plans. A well-rounded approach leads to better decision-making. Reflecting on these financial implications ensures that businesses can invest wisely.

When choosing a form fill machine, researching manufacturers and suppliers is crucial. Quality, support, and warranty options can significantly affect operations. A 2020 industry report noted that nearly 68% of businesses experienced production delays due to inadequate machine support. This emphasizes the importance of careful selection.

Look for manufacturers that offer robust warranties. A strong warranty often suggests confidence in product quality. According to the Packaging Machinery Manufacturers Institute, machines with warranties longer than three years tend to show higher reliability. Remember, one faulty component can disrupt an entire production line.

Support should include training and maintenance services. Many suppliers provide online resources, but hands-on training is invaluable. A survey found that 55% of operators felt more confident after proper training. Don't overlook this aspect; it can impact efficiency and safety. Also, consider the troubleshoot process. Responding to machine issues promptly can prevent costly downtime. Think critically about these factors as you choose the right machine for your business needs.