In today’s fast-paced manufacturing environment, the choice of packaging machinery can significantly impact operational efficiency and product presentation. Among the various options available, the vertical bagging machine has emerged as a preferred solution for many businesses. According to industry reports, the global vertical form fill seal (VFFS) packaging market is anticipated to grow at a CAGR of approximately 4.5% from 2021 to 2026, reflecting a robust demand for efficient packaging solutions across diverse sectors, including food, pharmaceuticals, and cosmetics.

Selecting the best vertical bagging machine involves several critical considerations, such as throughput capacity, bag specifications, and the nature of the product being packaged. For instance, recent studies indicate that companies using automated vertical bagging systems can achieve up to 30% higher productivity compared to manual packing processes. Furthermore, advancements in technology have led to machines that not only increase efficiency but also offer improved flexibility and reliability, catering to the evolving needs of modern businesses.

As stakeholders strive for greater sustainability and reduced operational costs, understanding how to choose the right vertical bagging machine becomes paramount. With options ranging from basic models to highly sophisticated systems equipped with smart technology, careful assessment and knowledge of the packaging landscape will enable businesses to make informed decisions that align with their specific requirements and growth objectives.

When selecting a vertical bagging machine, it's essential to understand the different types available to find the best fit for your packaging needs. Vertical bagging machines can be broadly categorized into two main types: form-fill-seal (FFS) machines and pre-made pouch fill machines. FFS machines create bags from a film roll, fill them with the product, and seal them in one continuous process. This type is ideal for high-speed production environments and helps reduce material waste. In contrast, pre-made pouch fill machines utilize pre-formed bags, allowing for greater versatility in bag shapes and sizes, making them suitable for products that require specific packaging aesthetics.

When choosing a machine, consider the product type and desired packaging speed. For bulk products like grains or powders, an FFS machine often results in faster output and less handling. Alternatively, if you’re working with delicate items or liquids, a pre-made pouch fill machine can offer better protection and tailored design.

**Tips**: Conduct a thorough analysis of your production volume and the materials you plan to package. Consider which machine type complements your workflow and meets your requirements for speed and efficiency. Also, keep in mind the maintenance and support options available for the machines, as these can greatly affect your long-term operational efficiency.

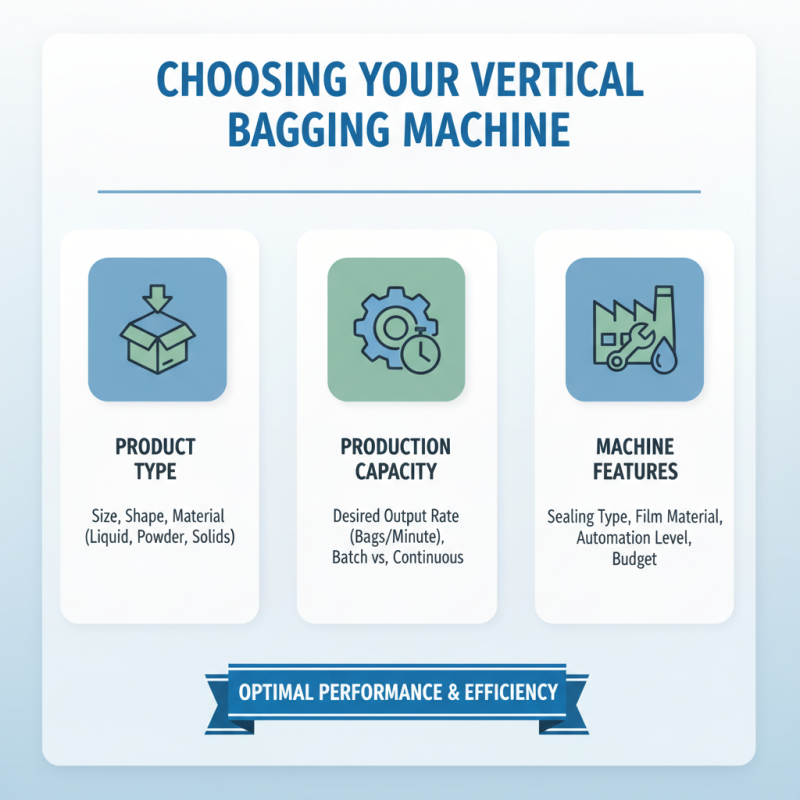

When choosing the best vertical bagging machine for your packaging needs, several key factors must be considered to ensure optimal performance and efficiency. First and foremost, you should assess the nature of your product. The size, shape, and material of what you plan to package significantly influence the machine's design and function. For instance, if your products are liquid or powdery, selecting a machine that can handle those specific characteristics is essential to avoid spillage and ensure precise filling.

Another critical factor is the production speed. Depending on your business requirements, you may need a machine that can operate at high speeds without compromising quality. Evaluating the machine’s flexibility is also vital; your packaging needs may evolve over time, so choose a model that can accommodate a variety of bag sizes and materials. Additionally, consider the ease of use and maintenance. A user-friendly interface and straightforward maintenance routines can enhance productivity and reduce downtime, making it easier for your operators to focus on their tasks. By carefully considering these factors, you can select a vertical bagging machine that aligns perfectly with your packaging requirements.

When selecting a vertical bagging machine, evaluating machine specifications is crucial for identifying a model that meets your packaging needs effectively. Key specifications to consider include the machine's speed, which is often measured in bags per minute (BPM). Industry standards suggest that efficient vertical bagging machines can operate at speeds between 30 to 100 BPM, depending on the product type and packaging complexity. A higher speed can significantly enhance productivity, but it must align with the quality of the seal and the integrity of the bags produced.

Another important specification is the machine's adjustable bag length capabilities. Flexible bag lengths not only accommodate various product sizes but also reduce material waste. According to recent reports, machines that offer a dynamic range of bag sizes can maximize operational efficiency by up to 20%, making it advantageous for companies with diverse packaging requirements. Moreover, the machine's compatibility with different materials, such as plastic or biodegradable film, is essential to ensure sustainable practices while meeting consumer demand for environmentally friendly options. By focusing on these specifications, businesses can invest in a vertical bagging machine that enhances both operational efficiency and product presentation.

When considering a vertical bagging machine, evaluating the cost versus the benefit is essential for making an informed decision. These machines can vary widely in price, influenced by factors such as their capabilities, speed, and precision. A higher upfront cost may be justified if the machine significantly boosts productivity, reduces labor needs, or minimizes material waste. Therefore, businesses should assess potential return on investment (ROI) by comparing the cost of the machinery with the expected efficiency gains and long-term savings.

In addition, businesses should consider the total cost of ownership, which includes maintenance, training, and operational costs alongside the initial purchase price. This comprehensive approach allows companies to understand the true financial implications of their investment. It's also beneficial to analyze how the machine will meet specific packaging needs and adapt to future requirements. A machine that may seem expensive at first could offer more value over time if it accommodates product variations and increases throughput effectively. Balancing these cost and benefit aspects will guide businesses to select a vertical bagging solution that aligns with their packaging goals.

| Feature | Description | Cost Range ($) | Benefit | Ideal For |

|---|---|---|---|---|

| Speed | Output speed of the machine, typically measured in bags per minute. | 5,000 - 20,000 | Increased productivity and efficiency in packaging. | High-volume production lines |

| Material Compatibility | Types of materials the machine can handle, such as films and foils. | 2,000 - 15,000 | Flexibility to package various products. | Diverse product lines |

| Ease of Use | How user-friendly the machine is regarding setup and operation. | 1,500 - 7,000 | Reduced training time and minimized operational errors. | Small businesses or newcomers |

| Maintenance | Frequency and cost of maintenance required to keep the machine operational. | 1,000 - 5,000 | Lower downtime and prolonged machine lifespan. | Operations with ongoing production |

| Customization Options | Availability of custom features like size and print options. | 3,000 - 12,000 | Branding opportunities and product differentiation. | Businesses focused on branding |

When selecting a vertical bagging machine, maintenance and support options play a crucial role in ensuring optimal performance and longevity of the equipment. According to a report by the Machinery Manufacturers Institute, approximately 25% of operational downtime in packaging facilities is attributed to machine maintenance issues. Regular maintenance not only reduces this downtime but also enhances the machine's efficiency, which is essential for maintaining high production standards. Organizations that invest in comprehensive maintenance plans, including scheduled inspections and prompt repairs, can improve the lifespan of their equipment by up to 30%.

Moreover, access to reliable technical support is equally vital. A survey conducted by Packaging Machinery Manufacturers Association highlights that 60% of manufacturers regard prompt customer service as a key factor in their overall satisfaction with packaging equipment. This underscores the importance of choosing a supplier that offers robust support options, including training for staff, quick response teams for troubleshooting, and readily available spare parts. Ensuring that you have the right maintenance and support options not only safeguards your investment but also elevates your packaging operation's reliability and productivity.