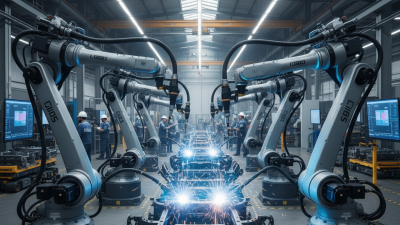

As industries evolve, so do the demands for efficiency and precision in manufacturing. In 2026, selecting the right robotic welding cell is more critical than ever. With advancements in technology, companies face a myriad of options. Each robotic welding cell boasts unique features designed to enhance productivity and quality. However, not every solution fits every need.

Choosing the best robotic welding cell requires careful consideration. Assess your specific production goals and the types of materials you will be working with. Factors like production speed, accuracy, and compatibility with existing systems matter. A robotic welding cell that excels in one area may fall short in another.

While modern options seem impressive, they can introduce complexities. High-tech cells might require extensive training for operators, which could lead to operational delays. Reflect on your team’s skills and adaptability. Ultimately, a well-chosen robotic welding cell aligns with your unique requirements, driving success in an increasingly competitive market.

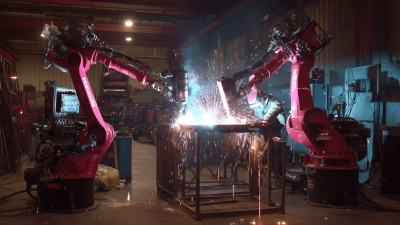

When choosing a robotic welding cell in 2026, understanding its key components is essential. A welding cell typically includes a robotic arm, welding machine, and control system. Each component plays a critical role in performance. The robotic arm should be versatile to handle various tasks. It must have a suitable reach and payload capacity for your specific needs.

**Tip:** Assess the workspace. The cell layout impacts efficiency. A cramped area can hinder performance. Think about how the robot will move and reach all necessary angles.

The welding machine is another vital part. It should match the materials you are working with. Different processes require different types of equipment. Look for features that enhance connectivity with the robotic arm and control system. Streamlined software can simplify operations.

**Tip:** Prioritize ease of use. Complex controls can lead to errors. Training staff on the system is critical for productivity. Consider how quickly your team can adapt to new technology.

Each choice shapes your overall efficiency. Match components to your production needs. Reflect on your processes regularly to ensure continuous improvement.

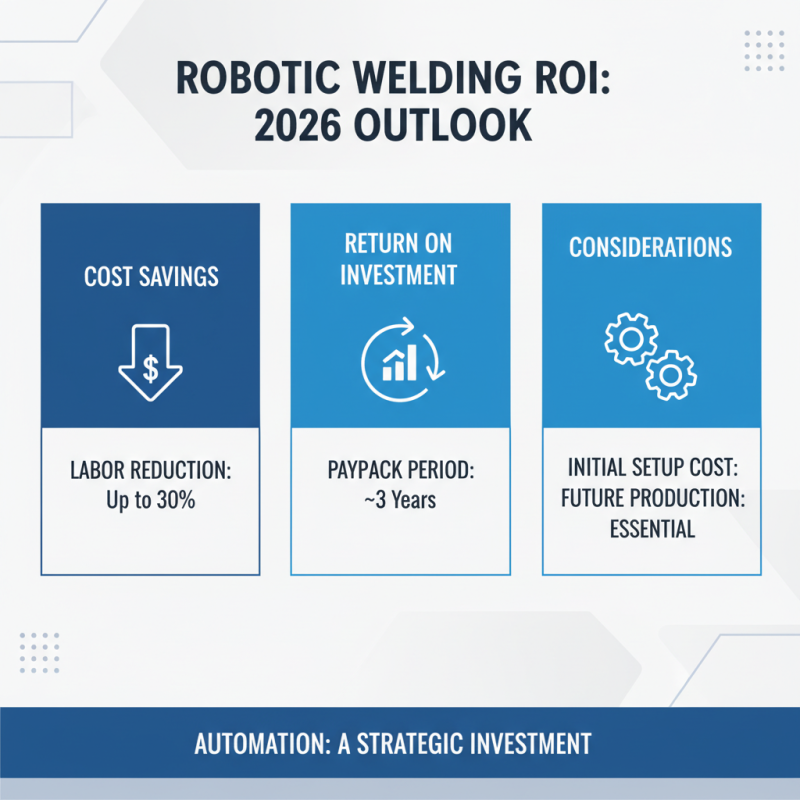

Evaluating the cost-effectiveness of robotic welding technology is vital for manufacturers in 2026. Automation can reduce labor costs by up to 30%. Many companies see a return on investment within three years. However, initial setup costs can be significant. Investing in a robotic welding cell often requires careful consideration of future production needs.

Production speed is another critical factor. Robotics can enhance welding speed by 50% compared to manual processes. But, not every process is suitable for automation. Certain projects may need skilled welders. Balancing automation with human expertise is essential.

Data from industry reports shows that robotic welding systems can improve quality consistency. Defects may drop by 70% with robotic precision. Yet, not all applications will yield the same results. Companies must assess their specific needs. Each project has unique challenges, and blind adoption of automation could lead to inefficiencies. A thoughtful approach will help align robotic systems with operational goals.

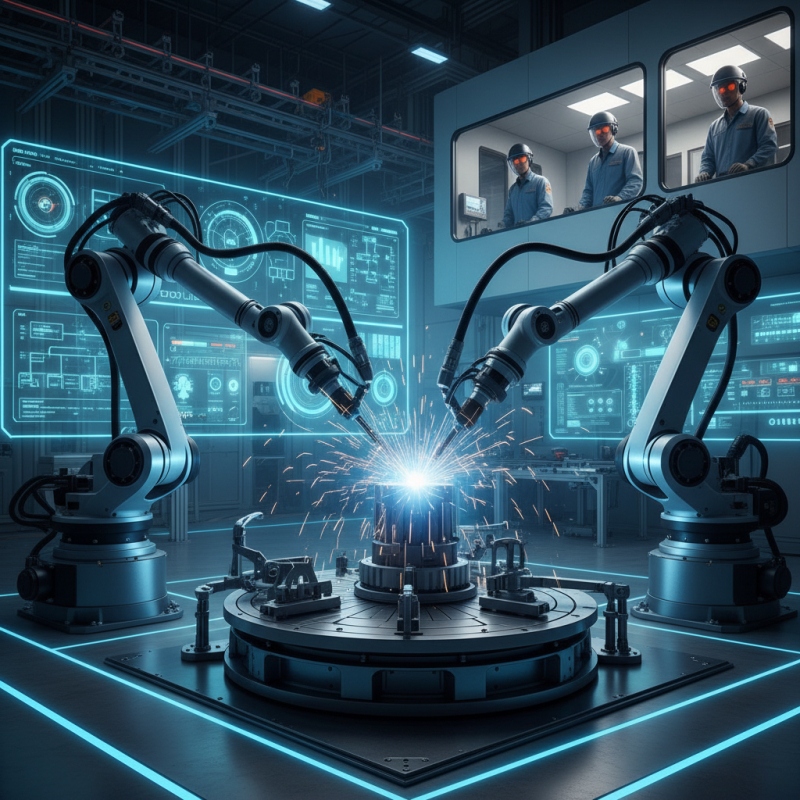

In 2026, assessing industry standards for robotic welding becomes crucial for manufacturers. The International Federation of Robotics reported a projected growth of 15% in the robotic welding market. This surge indicates the need for businesses to stay updated.

Safety is a primary concern. Reports reveal that 30% of welding injuries come from manual processes. Robotic cells equipped with advanced safety features can mitigate these risks. They have sensors and emergency stops to protect workers. However, not all robotic systems meet these safety benchmarks. It is vital to verify compliance with industry regulations.

Another factor to consider is efficiency. Data shows that robotic welding can enhance productivity by up to 50%. Yet, inefficiencies can arise if the system is not configured correctly. Some users report challenges in integrating new technology with existing processes. This gap highlights the importance of proper training and understanding of robotic systems. A focus on these standards ensures a more successful implementation.

When exploring robotic welding cells in 2026, identifying the best brands is essential. You'll want to research various models that fit your specific welding requirements. Consider capacity, precision, and ease of use. These factors are crucial for efficiency. Different manufacturers offer various features, which can be overwhelming. It’s vital to narrow down the options that align with your production goals.

Evaluate the technology behind the models you consider. Some may boast advanced programming capabilities, while others focus on durability and maintenance. Make a list of must-have features for your needs. Test run some options when possible. This will provide a practical feel and highlight any shortcomings. Always reflect on how each model can adapt to future projects. The right choice today should also accommodate growth tomorrow.

In your quest for the perfect robotic welding cell, brand reputation matters, but don’t overlook user reviews. Hearing from current users can reveal strengths and weaknesses you may not have noticed. Even the best brands may falter in certain areas. Balancing cost with performance is another factor that needs careful consideration. Take your time and gather as much information as possible before making a decision.

In 2026, customizing robotic welding solutions becomes crucial. Each industry has unique demands. A one-size-fits-all approach may not suffice. Consider the specific applications you need. Are you working with

delicate materials or heavy-duty tasks? Each scenario requires different settings and tools. Fine-tuning your robotic system can mean the difference in production quality.

Understanding your production flow is essential. Assess how the robot interacts with other machinery. Sometimes, the integration process reveals unexpected challenges. For instance, a robot may face issues while transitioning between tasks. This friction points to the need for better customization. Choose options that allow

modular adjustments. Your choice will impact performance over time. Regular reflections on workflow efficiency can guide improvements.

Another aspect to ponder is the training required for your team. Operators need to understand the customization features. If they struggle to use advanced settings, inefficiencies arise. Providing adequate training is just as important as the robot's capabilities.

Consider this balance when choosing a solution. Focus not only on specifications but also on usability and support.