In today's rapidly evolving packaging industry, the demand for efficiency, accuracy, and cost-effectiveness has led to a surge in the adoption of automated solutions. Among these, the **form fill seal machine** stands out as a pivotal technology that streamlines the packaging process, enabling manufacturers to maintain competitiveness in an increasingly saturated market. According to a recent report by Smithers Pira, the global market for packaging machinery is projected to reach $50 billion by 2025, with form fill seal machines playing a significant role in this growth due to their ability to reduce labor costs and enhance productivity.

Choosing the right form fill seal machine for your business needs is crucial, as it can impact not only operational efficiency but also product quality and customer satisfaction. Different industries, from food and beverage to pharmaceuticals, require specific machine features to meet varying regulatory standards and consumer expectations. A comprehensive analysis by MarketsandMarkets indicates that the demand for flexible packaging solutions—often employing form fill seal technology—is growing at a CAGR of 4.4%, highlighting the necessity for businesses to carefully assess their requirements when selecting machinery that can adapt to future needs.

As we explore how to choose the best form fill seal machine, it is vital to consider factors such as production volume, packaging materials, and required machine versatility. This understanding will empower businesses to invest wisely in technology that not only meets current operational demands but also supports future scalability and innovation in packaging solutions.

Understanding Form Fill Seal Machines and Their Applications

Form fill seal (FFS) machines have revolutionized the packaging industry by providing a streamlined approach to packaging various products. These machines create a pouch or bag from a flat roll of film, fill it with the desired product, and then seal it efficiently. FFS machines are widely used across multiple sectors, including food and beverage, pharmaceuticals, and cosmetics, due to their versatility and high-speed capabilities. They not only enhance productivity but also reduce labor costs and minimize material waste, making them an ideal choice for businesses looking to optimize their packaging processes.

Tips: When selecting a form fill seal machine, consider the type of product you will be packaging. Different machines are designed for varying product consistencies and packaging styles. Additionally, evaluate the machine's ease of use and maintenance requirements, as these factors can significantly impact your operational efficiency.

Another key aspect to consider is the machine's flexibility in handling different sizes and formats. Some FFS machines can be easily adjusted to accommodate changes in product size or packaging design, which is essential for businesses that frequently introduce new products. Ensure that the chosen machine can adapt to your future needs to maximize your investment.

When choosing the best form fill seal machine for your business needs, it's essential to focus on several key features that can significantly impact your production efficiency and product quality. First and foremost, consider the machine’s capacity and speed. Understanding your production volume requirements will help you choose a machine that can keep pace with your needs, reducing downtime and increasing productivity.

Another critical feature to evaluate is the versatility of the machine. Look for machines that can handle various types of packaging materials and formats, as this flexibility allows you to adapt to changing market demands. Additionally, features like easy changeover times and user-friendly interfaces can simplify operations and reduce training time for your workforce.

**Tip:** Always check for a machine that offers robust safety features and complies with industry standards. This not only protects your employees but also ensures your production process is efficient and reliable.

Lastly, consider the machine's maintenance and support requirements. Investing in a machine that comes with comprehensive technical support and a straightforward maintenance schedule can save your business time and money in the long run. Regular upkeep is crucial in preventing breakdowns, ensuring that your operations run smoothly without unexpected interruptions.

When selecting the best form fill seal (FFS) machine for your business, a critical factor to consider is the production capacity and efficiency requirements tailored to your operational goals. According to a report by Grand View Research, the global form fill seal packaging market is projected to reach $30.95 billion by 2025, indicating a growing demand for efficient packaging solutions. This growth underscores the necessity for businesses to invest in machines that can optimize their production lines without compromising on quality.

Assessing production capacity involves determining both the volume and speed required for your products. For instance, if your business expects to produce large quantities, look for machines that can achieve high output rates, typically ranging from 30 to 120 bags per minute, depending on the complexity of the packaging. Moreover, efficiency is not just about speed; it also encompasses machine reliability and the ability to reduce downtime. A well-configured FFS machine can significantly enhance productivity. According to PMMI, the Packaging Machinery Manufacturers Institute, improving machine efficiency by as little as 5% can lead to substantial cost savings and improved overall throughput in production processes. Thus, understanding your specific needs in capacity and efficiency will guide you in selecting the ideal FFS machine that supports sustained growth and competitiveness in the packaging sector.

This chart illustrates the estimated production capacity in units per hour for various types of Form Fill Seal machines from 2022 to 2025. As businesses assess their production capacity needs, understanding how different machines compare can help in making informed decisions.

When selecting a form fill seal machine for your business, evaluating cost-effectiveness is crucial to ensure that your investment aligns with your operational requirements. Start by assessing your production volume and the types of products you will be packaging. A machine that offers versatility in packaging sizes and materials can provide long-term financial benefits by accommodating growth and changes in your product line. It's important to analyze not only the purchase price of the machine but also the costs associated with its operation, including maintenance, labor, and the materials used during the filling and sealing processes.

Budget considerations extend beyond immediate costs; consider the total cost of ownership over the machine's lifespan. Assess potential downtime and repair costs, and factor in the training requirements for your staff to operate the machine efficiently. Investing in a slightly more expensive machine that is durable and requires less frequent repairs may prove more economical in the long run. Additionally, it's wise to evaluate financing options or lease arrangements that can ease upfront costs, making it easier for your business to manage cash flow while still acquiring the necessary equipment to meet production demands effectively.

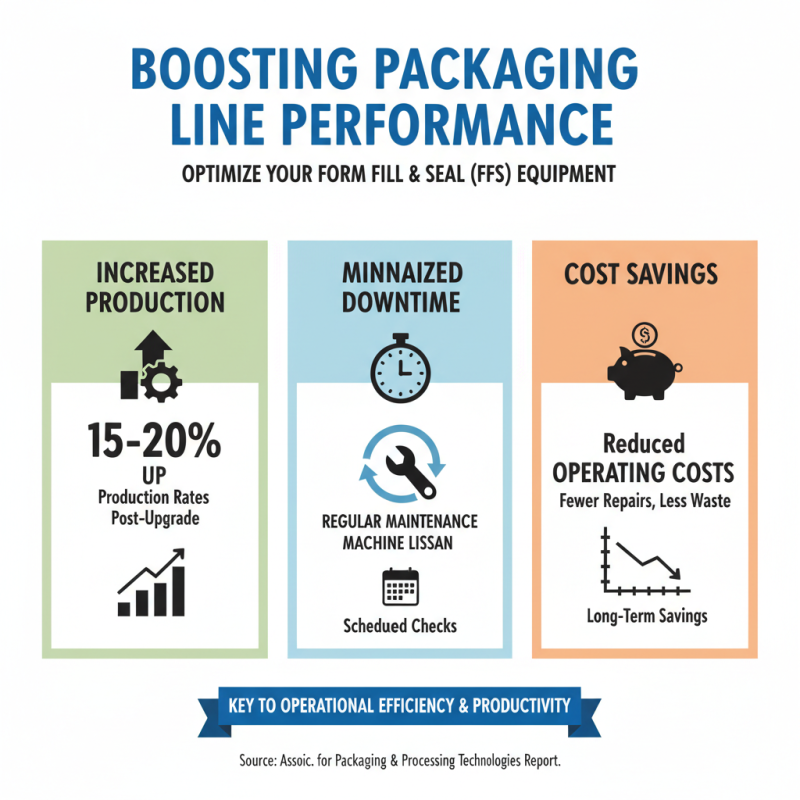

Maintaining and upgrading your form fill seal (FFS) equipment is crucial for ensuring operational efficiency and maximizing productivity in packaging lines. According to a recent report by the Association for Packaging and Processing Technologies, manufacturers often see a 15-20% increase in production rates after implementing modern maintenance practices and technology upgrades. Regularly scheduled maintenance not only minimizes downtime but also extends the lifespan of the machinery, resulting in significant cost savings over time.

Moreover, upgrading components of your FFS machine can lead to enhanced functionality and flexibility in handling various materials and package formats. Industry benchmarks suggest that integrating advanced technologies such as automation and intelligent control systems can increase throughput by up to 30%. As businesses face growing consumer demand for varied packaging options, investing in state-of-the-art upgrades can ensure that your operations remain competitive and responsive to market trends. This proactive approach to equipment maintenance and upgrades not only optimizes performance but also aligns with sustainability goals by improving energy efficiency and reducing waste.