In today's rapidly evolving industrial landscape, the choice of automation machinery can significantly impact a business’s efficiency and productivity. As James Anderson, a renowned expert in industrial automation, emphasizes, "The right automation machinery not only streamlines operations but can also unlock new levels of innovation and competitiveness." As more businesses seek to harness the power of automated solutions, understanding how to select the best machinery tailored to specific needs becomes crucial.

Choosing the right automation machinery involves a comprehensive evaluation of various factors, including operational requirements, budget constraints, and long-term goals. With a plethora of options available in the market, it can be overwhelming for business owners to identify which machines will optimize their processes and yield a substantial return on investment. In this context, a methodical approach to assessing machinery features, compatibility with existing systems, and scalability can make all the difference.

Ultimately, the choice of automation machinery is not just about adopting the latest technology but rather finding a solution that aligns with the unique demands of each business. By leveraging expert insights and conducting thorough assessments, businesses can confidently navigate the complexities of automation, driving both short-term results and long-term success.

Automation machinery has become a cornerstone for businesses seeking to enhance efficiency, reduce operational costs, and improve overall productivity. According to a report by McKinsey & Company, companies that effectively implement automation technologies can improve their productivity by up to 30% within three years. This is particularly critical in industries such as manufacturing, logistics, and retail, where the demand for increased output and streamlined processes is ever-growing. By utilizing automation, businesses can not only optimize labor costs but also minimize human errors, leading to higher quality outputs.

Furthermore, the importance of automation machinery is underscored by recent studies from the International Federation of Robotics, which indicate that global sales of industrial robots are on track to reach 500,000 units annually by 2025. This rapid adoption rate illustrates the urgency for businesses to integrate these advanced technologies into their workflows. Automation machinery supports real-time data analysis and decision-making processes, enabling businesses to respond swiftly to market changes and customer demands. As companies continue to recognize the benefits of automation, the investment in these technologies is projected to significantly rise, reinforcing their necessity in maintaining competitive advantage in today's dynamic market landscape.

When considering automation machinery for your business, the first step is to clearly identify your specific needs and goals. This involves evaluating your current processes, understanding the areas where efficiency can be improved, and determining the tasks that are repetitive or time-consuming. Engage with your team to gather insights on bottlenecks and challenges they face daily. Documenting these requirements not only helps in clarifying the scope of automation but also sets measurable objectives that can guide the selection process.

Once you have a comprehensive understanding of your operational needs, it's essential to align those with your long-term business goals. Are you looking to reduce costs, increase production capacity, or enhance product quality? Prioritizing these goals will help you evaluate different automation solutions effectively. Consider factors such as scalability and flexibility when choosing machinery, ensuring that it can grow alongside your business or adapt to changes in your production line. By intricately linking your automation strategy to your overarching business objectives, you can make informed decisions that drive both immediate improvements and future growth.

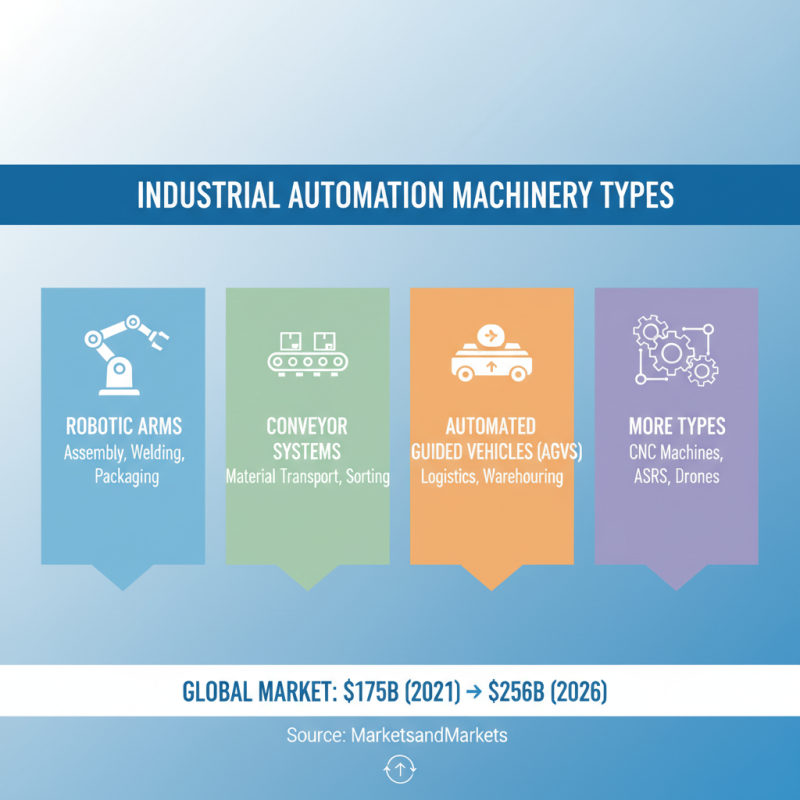

When evaluating different types of automation machinery available in the market, it’s essential to consider the specific needs of your business. Automation machinery can be broadly categorized into several types, including robotic arms, conveyor systems, automated guided vehicles (AGVs), and more. According to a report by MarketsandMarkets, the global industrial automation market is projected to grow from approximately $175 billion in 2021 to over $256 billion by 2026, driven by the increasing need for efficiency and productivity across various industries. Understanding the functionalities and applications of each type can significantly impact operational efficiency.

For instance, robotic arms are primarily suitable for repetitive tasks that require precision, such as assembly or welding, while conveyor systems streamline the movement of goods within a facility, reducing manual labor and minimizing errors. Additionally, AGVs are gaining traction in warehousing and distribution sectors, as they enable flexible and efficient movement of materials without the need for manual intervention. A survey conducted by the Association for Advancing Automation (A3) highlighted that manufacturers implementing automation solutions have seen productivity increases by up to 25%, emphasizing the importance of choosing the right machinery tailored to specific operational tasks. As market options continue to expand, businesses should rigorously assess their individual requirements and the potential return on investment when selecting automation machinery.

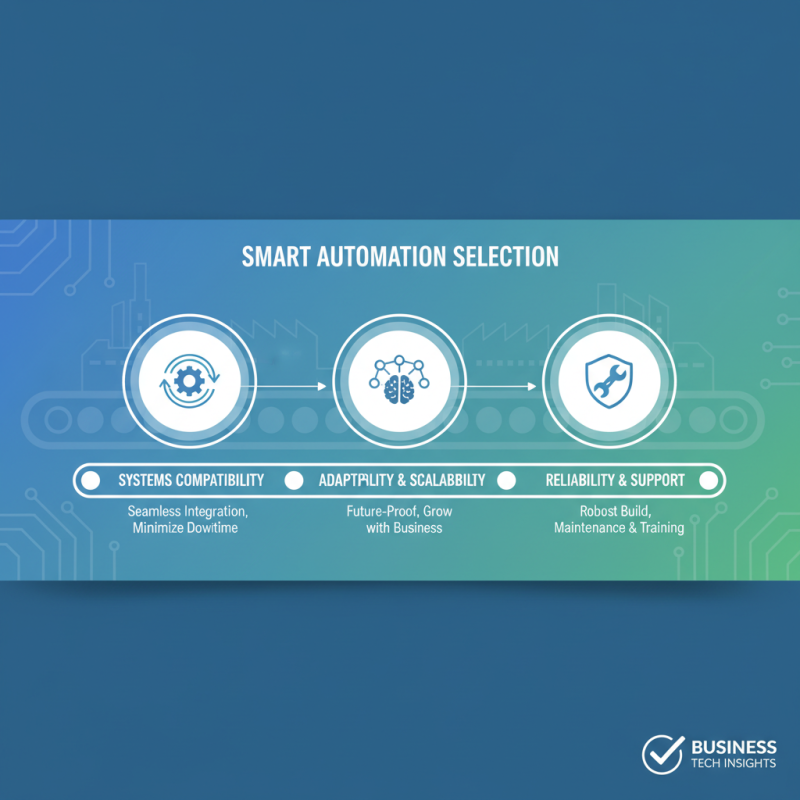

When selecting automation machinery for your business needs, it's crucial to focus on a few key features that can significantly impact your operations. Firstly, consider the machinery's compatibility with your existing systems. Ensure that the equipment can seamlessly integrate with your current workflows to enhance efficiency and minimize downtime. A smooth integration process can help streamline production and reduce the learning curve for your staff.

Another important feature to evaluate is the scalability of the automation machinery. As your business grows, your automation needs may change. It is essential to choose machinery that can easily adapt to increased production demands without requiring significant investment in additional equipment. This flexibility can save costs in the long run and make it easier to respond to market changes.

**Tips:** Always assess the support and maintenance services offered by the manufacturer. Having reliable after-sales support can make a big difference when issues arise or during regular maintenance. Additionally, conduct a cost-benefit analysis to ensure that the long-term benefits of the automation machinery outweigh the initial investment. Opting for a machine that has demonstrated longevity and reliability in similar applications can provide peace of mind and confidence in your purchase.

When considering automation machinery for your business, budgeting and cost analysis are pivotal in ensuring a sound investment. According to a report by the International Federation of Robotics, the global market for automation technology is projected to grow by over 10% annually over the next five years. This significant growth highlights the importance of thorough financial planning. Businesses need to assess initial capital outlay, operational costs, and long-term savings that automation can provide. A detailed analysis can reveal the potential return on investment (ROI) based on increased efficiency and reduced labor costs, making it a critical factor in decision-making.

Moreover, a study conducted by McKinsey & Company found that companies can save between 20-30% on operational costs by implementing automation. This data emphasizes the necessity of factoring in maintenance costs and potential downtime during initial setup when budgeting. Organizations should also include potential costs associated with training employees to operate new machinery, as investing in workforce development can further enhance the machinery's value. By conducting comprehensive cost analysis and budgeting, businesses can not only optimize their automation choices but also align them strategically with their financial capabilities and growth objectives.

| Automation Machinery Type | Initial Cost ($) | Maintenance Cost/Year ($) | Expected Lifespan (Years) | Return on Investment (%) |

|---|---|---|---|---|

| Robotic Arm | 50,000 | 5,000 | 10 | 150 |

| Automated Conveyor System | 75,000 | 7,500 | 15 | 130 |

| Automated Pick and Place System | 60,000 | 6,000 | 12 | 145 |

| Laser Cutting Machine | 100,000 | 10,000 | 8 | 120 |

| Packaging Machine | 40,000 | 3,500 | 10 | 160 |