Choosing the right vertical bagging machine can significantly impact your business’s efficiency and output. According to John Smith, a veteran in the packaging industry, “The right machine can revolutionize your production line.” Understanding your specific needs is essential.

When evaluating vertical bagging machines, factors like speed, versatility, and ease of use come into play. Each industry has unique requirements. A snack food company might need different features compared to a pharmaceutical firm. Ignoring these differences could lead to wasted resources. The selection process can be daunting and requires careful consideration.

Size and type of packaging materials should not be overlooked. Some machines perform well with certain materials and struggle with others. It's crucial to test various options. After all, not every vertical bagging machine is perfect for every application. Reflection on past choices can often guide better decisions.

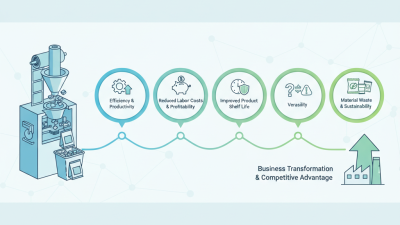

Choosing the right vertical bagging machine is crucial for business efficiency. When selecting one, consider productivity needs. A machine with a higher output can enhance production rates. Reports indicate that companies using advanced vertical bagging technologies see a 30% increase in packaging speed.

Look at the machine's adaptability. It should handle various bag sizes and materials. Flexibility can save your business from additional costs related to equipment changes. It's essential to evaluate how easily the machine integrates into your existing setup. Some businesses find this aspect challenging, leading to downtime and lost revenue.

Tips: Always check for user-friendly interfaces. Machines that are easy to operate reduce training time. Also, remember to factor in maintenance costs. Over time, these costs can add up. Investing in a machine that offers reliability can mitigate unexpected expenses. Keep in mind that not all machines meet every need perfectly. So a little research goes a long way.

When selecting a vertical bagging machine, it’s crucial to understand the various types available in the market. There are several options, each designed for specific needs. For example, a vertical form-fill-seal machine is ideal for packing products like snacks and powders. It uses rolls of film to create bags on-site. This process can save time and money.

Another option is the vacuum bagging machine. It's perfect for products that require a reduced oxygen environment, such as meats or cheeses. These machines remove air before sealing. However, they may require more maintenance. It's important to assess whether frequent cleaning will hinder your production speed.

Finally, consider the size and weight capacity of the machine. Some models can handle larger volumes but require more floor space. Can your facility accommodate this? Think about your future needs as well. Investing in a machine that's too small may lead to operational issues later. Balancing current demand and future growth is essential.

| Type of Vertical Bagging Machine | Features | Best For | Price Range (USD) |

|---|---|---|---|

| Standard Vertical Bagging Machine | Simple design, suitable for a variety of products | Snack foods, granules | $10,000 - $20,000 |

| Multi-Head Weigher Bagging Machine | High-speed filling with multiple weigh heads | Powder, granules | $20,000 - $35,000 |

| Vacuum Vertical Bagging Machine | Removes air to preserve freshness | Perishables, snacks | $15,000 - $25,000 |

| High-Speed Vertical Form Fill Seal Machine | Fast production, customizable bag sizes | High-volume packaging | $30,000 - $55,000 |

| Auger Filling Vertical Bagging Machine | Accurate filling for powdered products | Powders, granular materials | $18,000 - $28,000 |

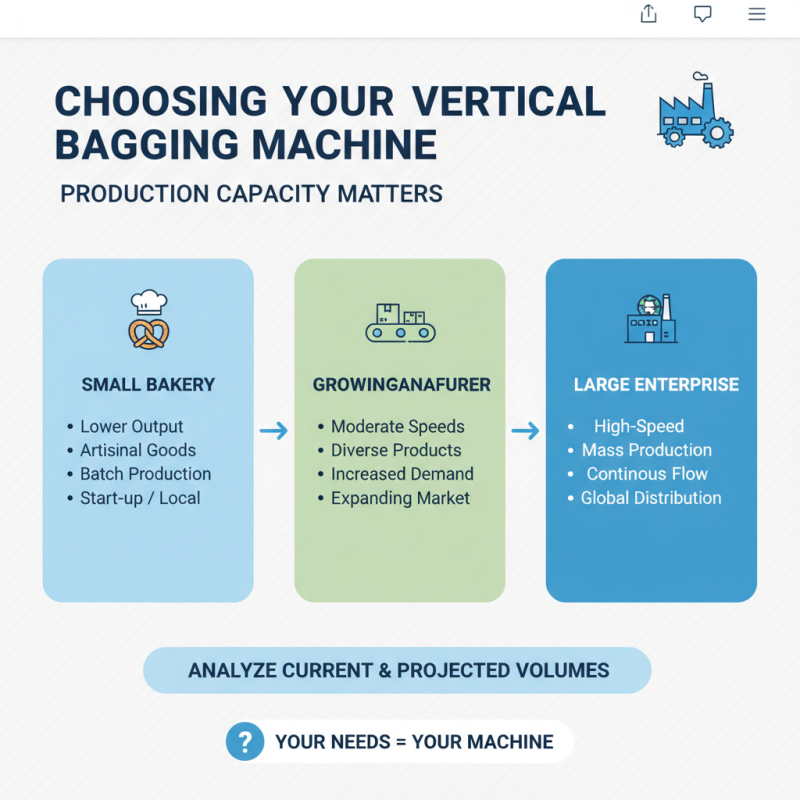

Choosing the right vertical bagging machine begins with evaluating your production capacity requirements. Understanding your output needs is crucial. For instance, a small bakery may require lower production rates, while a large manufacturer needs high-speed capabilities. Analyze your current and projected production volumes. This insight will guide your selection process.

Consider the types of products you plan to package. Are they dry or wet? Granular or liquid? Each product type imposes its own requirements on the machine. For example, granules need precise filling to avoid spills, while liquids demand tight seals to prevent leaks. Reflecting on these factors may lead to realizations about your specific needs.

Don’t rush into a decision. Test different machines if possible. Sometimes, what seems ideal on paper may not work effectively in practice. Gather feedback from your team who will operate the machine. Their insights are valuable. Ensuring the equipment fits well with your workflow is paramount for efficiency. Consider every detail to make an informed choice for your business.

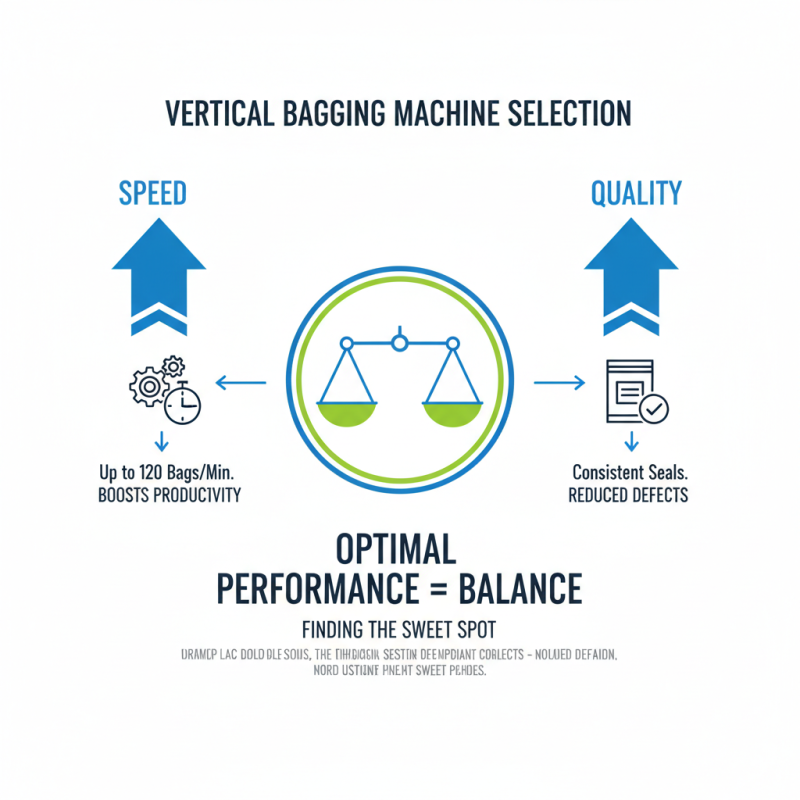

When selecting a vertical bagging machine, several key features warrant attention. The machine's speed is crucial. Many devices can produce up to 120 bags per minute, which enhances productivity. However, too much speed may compromise quality. It’s essential to balance these factors to ensure optimal performance.

Next, consider the adaptability of the machine. A versatile vertical bagger should handle various bag sizes and materials. Some machines can accommodate bags from 5 to 50 microns thick. Flexibility can reduce switching time between products. In today’s market, flexibility often determines profit margins.

Another critical feature is the ease of maintenance. Regular upkeep is vital for continuous operation. According to industry reports, over 25% of downtime comes from equipment failure. A machine designed for simple maintenance can save a business both time and money. However, not all machines provide this designing ease, leading to potential operational inefficiencies. Thus, careful evaluation is essential.

Investing in a vertical bagging machine can be a game-changer for businesses. However, assessing the budget and potential return on investment (ROI) is crucial. A well-planned budget should include not only the purchase cost but also operating expenses, maintenance, and potential downtime losses. Consider other costs too, like training for staff and any needed upgrades to your facility.

When calculating ROI, it’s essential to estimate how the machine will improve efficiency and reduce labor costs. A suitable machine should ideally pay for itself within a few years. A thoughtful analysis of your production needs will help in making a well-informed choice. Are your production goals realistic?

Tips for budgeting include prioritizing essential features that match your workflow and production speed. Avoid overspending on unnecessary extras that won't increase productivity. Always factor in small, ongoing expenses as they add up. Lastly, don’t hesitate to reevaluate your needs after initial implementation. Your business may evolve, and so could the best choice of machinery.