Choosing the right horizontal form fill seal machine can be challenging. Various factors must be considered. These machines are versatile and essential for packaging.

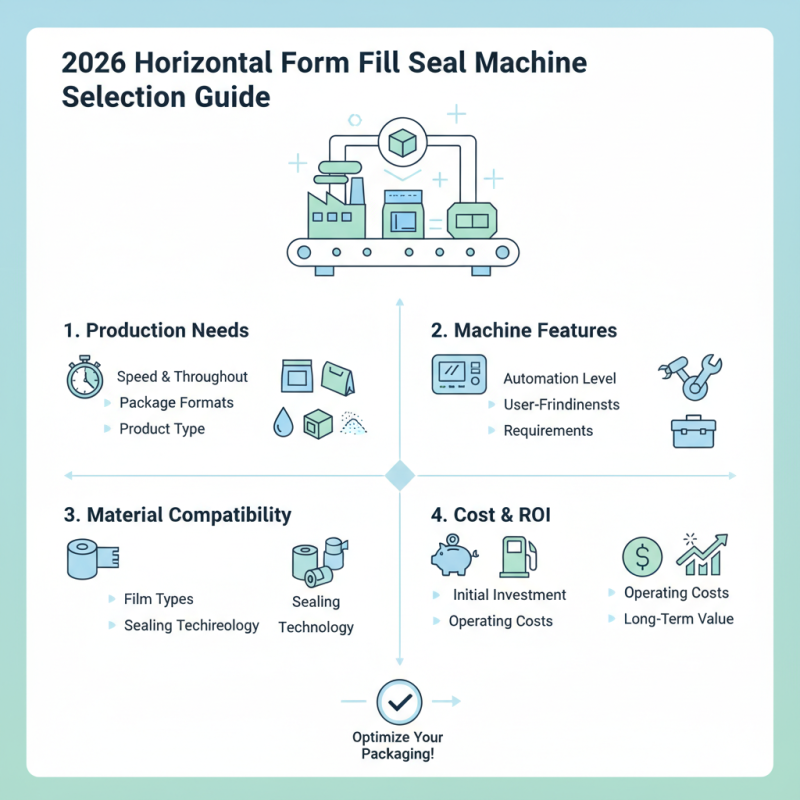

First, think about your production needs. Different models handle various speeds and formats. It's crucial to assess your specific requirements. Consider the types of products you package. Some machines perform better with liquids, while others excel with solids or powders.

Also, evaluate the machine's features. Automation levels can significantly impact efficiency. Make sure to analyze user-friendliness. A complex machine can lead to mistakes. Additionally, reflect on maintenance needs. Some machines require more upkeep than others. Balancing efficiency and practicality is key.

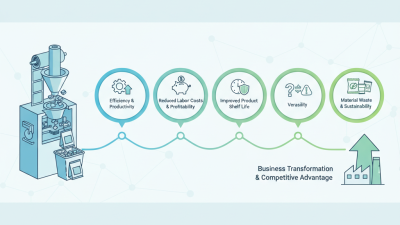

Horizontal Form Fill Seal (HFFS) machines play a vital role in packaging. They create bags from flat rolls of film, filling them with products, and sealing them shut. This process is efficient for various industries, including food, pharmaceuticals, and consumer goods. Understanding these machines can help manufacturers improve packaging quality and reduce waste.

Choosing the right HFFS machine is not straightforward. There are multiple factors to consider, like bag dimensions and product types. Each product requires a specific sealing method. Some machines struggle with thicker films, while others work best with lighter materials. Proper training is essential. Users must understand machine settings and maintenance for optimal performance. Mistakes here can lead to downtime and increased costs.

It's also crucial to analyze production speed. Machines with higher speeds may offer greater efficiency but often come with complexity. Finding the right balance is challenging. Operators must regularly reflect on which settings yield the best results. Continuous improvement in processes is a must, as each small adjustment can significantly impact overall productivity.

Choosing the right horizontal form fill seal machine requires careful consideration of various factors. One key aspect is the machine's production speed. You need a machine that can keep up with your output needs. Think about the transition time when switching products. A fast changeover can save you a lot of downtime.

Material compatibility is another crucial factor. Ensure that the machine can handle the types of packaging film you intend to use. Certain materials may require specific sealing techniques. Don't overlook the importance of sealing quality. A poor seal can lead to product spoilage. Inspect the machine specifications for sealing temperature and pressure.

Tips: Test the machine with your actual packaging materials before purchasing. This can reveal any unforeseen compatibility issues. Also, consider the machine's maintenance needs. A machine that requires frequent repairs can be a burden. Evaluate the support offered by the manufacturer. Having reliable service can make a big difference in your operations.

Lastly, think about the footprint of the machine. Will it fit in your production area? Space limitations can be a significant challenge. Don’t forget to think about scalability. Your needs may change, and you don't want to invest in equipment that can't adapt.

When selecting a horizontal form fill seal (HFFS) machine, it’s crucial to compare the various types available. The market offers diverse options tailored for specific packaging needs. Some machines are designed for high-speed production, while others focus on flexibility for different products. Understanding the unique features of each type can lead to better decisions.

For example, continuous motion machines provide higher speeds, making them ideal for bulk products. In contrast, intermittent motion machines offer versatility in packaging sizes. Choosing the right type depends on your production volume and product type. A report from Smithers Pira states that the HFFS market is expected to grow by 5% annually until 2026. This reflects a rising demand for efficient packaging solutions.

Tips: Always assess the machine's scalability. Does it grow with your business? Consider production layout too. A poorly placed machine can slow operations. Analyze the automation level as well. Higher automation may require more initial investment but can enhance efficiency.

While these factors are critical, don't overlook maintenance. Machines with complex mechanisms might pose challenges. Regular upkeep can prevent unexpected downtime, impacting production flow. Thus, choosing an HFFS machine isn't just about features; it's about your overall production strategy.

| Machine Type | Speed (Packages/min) | Film Type | Application | Price Range ($) |

|---|---|---|---|---|

| Intermittent Motion | 30-120 | Plastic, Paper | Snacks, Bakery | 10,000 - 50,000 |

| Continuous Motion | 100-300 | Plastic Film | Confectionery, Frozen Food | 30,000 - 100,000 |

| Vertical Integration | 50-150 | Aluminum Foil, Plastic | Healthcare, Consumer Products | 25,000 - 75,000 |

| Flexible Packaging | 40-200 | Biodegradable Film | Organic Products, Snacks | 20,000 - 60,000 |

When selecting a horizontal form fill seal machine, evaluating features and specifications is crucial. Various aspects influence the machine's efficiency and suitability for specific applications. According to industry data, the global market for these machines is expected to grow by 5.2% annually from 2023 to 2028. This growth underscores the need for careful consideration of machinery characteristics.

Look for machines that offer adjustable fill volumes. Flexibility can enhance productivity. It allows you to handle varying product sizes efficiently. Also, consider speed and throughput rates. Machines that can achieve more than 100 packs per minute can drastically improve your production line's efficiency.

Tips: Don’t overlook the importance of ease of maintenance. A complex machine can lead to downtime and increased costs. Analyze the control systems as well. Intuitive interfaces can reduce training time and errors.

Pay attention to the materials supported by the machine. Some machines are limited in the types of films they can use. This can restrict your packaging options. Ensure the machine aligns with your product specifications and future needs.

When selecting a horizontal form fill seal (HFFS) machine, assessing manufacturer support is crucial. A reliable manufacturer provides not just a quality machine but also ongoing support. Consider the availability of customer service. Are they reachable easily? Quick response times can save you from downtime.

Tips: Research online reviews about customer service experiences. Ask other businesses about their interactions. Sometimes, feedback reveals much about reliability.

Evaluate the training and resources offered. Does the manufacturer provide detailed manuals or video training? This can significantly impact your team's efficiency. Lack of adequate training can lead to operational mistakes. It’s worth questioning how much support you'll really receive after the sale.

Tips: Request training demos before purchase. Sometimes, you need to see the training process in action. It’s important to ensure your team feels confident with the new machine. Don't overlook the importance of spare parts availability. If a machine goes down and parts are hard to get, it can cost you.