The landscape of automation is rapidly evolving, thanks in large part to advancements in vision guided robotics. These systems leverage sophisticated vision technologies to enhance the accuracy and efficiency of automated processes across various industries. According to a report by MarketsandMarkets, the global market for vision guided robotics is projected to grow from USD 1.4 billion in 2021 to USD 3.9 billion by 2026, at a CAGR of 22.5%. This significant growth is indicative of the increasing demand for automation solutions that can adapt to complex environments and perform intricate tasks with minimal human intervention.

As industries strive for higher efficiency and productivity, the integration of vision guided robotics presents unique opportunities. These robotic systems are designed to identify, pick, and place items with precision, reducing errors and maximizing throughput. In fact, a study by the International Federation of Robotics indicates that the implementation of vision systems in robotic applications is expected to enhance operational performance by up to 30%, especially in manufacturing and logistics sectors. As companies continue to embrace digital transformation, investing in vision guided robotics solutions is becoming a strategic imperative for maintaining competitiveness in a fast-paced market landscape.

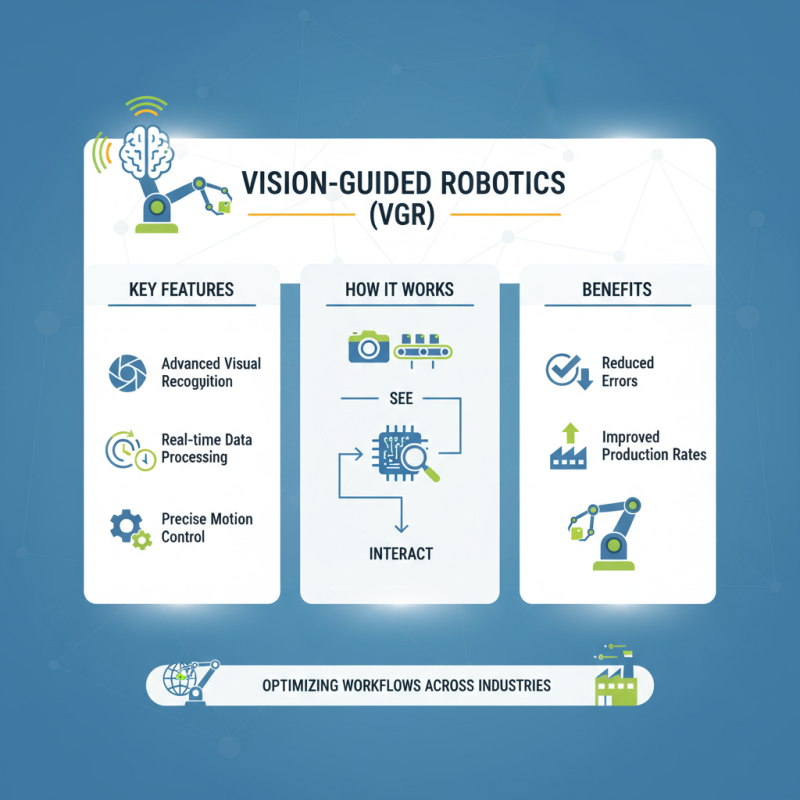

Vision guided robotics (VGR) is revolutionizing automation across various industries by integrating sophisticated imaging systems with robotic technologies. The key features of VGR include advanced visual recognition capabilities, real-time data processing, and precise motion control. These systems enable robots to identify, analyze, and interact with objects in their environment, enhancing their efficiency and adaptability. As a result, VGR can significantly reduce errors and improve production rates, making it an invaluable tool for manufacturers looking to optimize their workflows.

Tips for implementing vision guided robotics in your automation processes include conducting a thorough assessment of your current systems to identify compatibility issues. Ensure you select the right imaging technology that meets your application needs, whether it involves 2D or 3D vision solutions. Training your staff on how to operate and maintain these systems is also crucial, as it maximizes the investment made in these advanced technologies. Regularly reviewing performance metrics will help you gauge the effectiveness of VGR and allow for adjustments that enhance operational efficiency.

Another critical feature of VGR is its flexibility. By utilizing software that can be easily programmed or modified, these systems can adapt to different tasks without extensive downtime. This versatility allows businesses to pivot more quickly in response to market needs, making VGR a key player in the future of automation. Implementing standardized protocols for troubleshooting and updates can further sustain the long-term functionality of these systems.

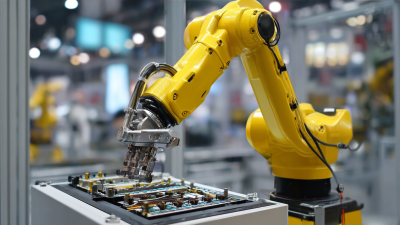

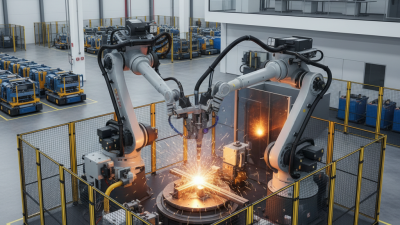

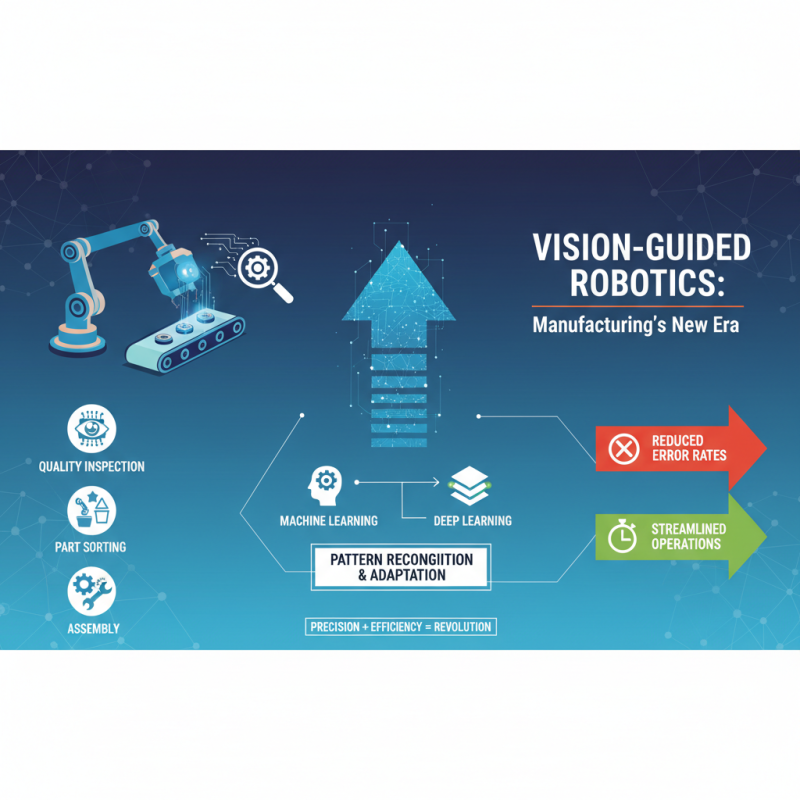

Vision guided robotics (VGR) has been a game-changer in various industries, revolutionizing the way automation is implemented. The manufacturing sector stands at the forefront of this transformation, where precision and efficiency are paramount. Robotics equipped with advanced vision systems are now capable of performing intricate tasks such as quality inspection, part sorting, and assembly. By utilizing machine learning algorithms and deep learning techniques, these systems can recognize patterns and adapt to different production environments, significantly reducing error rates and streamlining operations.

Another key area harnessing the benefits of vision guided robotics is logistics and warehousing. As e-commerce continues to grow, the demand for efficient inventory management and distribution processes has surged. VGR solutions can autonomously navigate complex warehouse layouts, accurately identify products, and manage stock levels. This not only speeds up the picking and packing processes but also enhances overall supply chain efficiency. By integrating VGR into logistics, companies can achieve higher throughput, reduce operational costs, and improve customer satisfaction through quicker delivery times. Overall, the adoption of vision guided robotics is profoundly impacting various industries, paving the way for smarter, more efficient automation solutions.

Vision-guided robotics (VGR) represents a pivotal advancement in automation technology, allowing machines to interpret and interact with their environments by utilizing sophisticated vision systems. The comparative analysis of leading VGR technologies unveils significant variations in their capabilities, precision, and adaptability across different industrial applications. Key players in this field employ diverse techniques ranging from machine learning algorithms to advanced imaging systems, enabling robots to handle complex sorting, assembly, and inspection tasks.

Among the most notable technologies is the implementation of 2D and 3D vision systems that enhance depth perception and spatial awareness. These systems allow robots to accurately identify and manipulate items, even in cluttered or dynamic settings. Furthermore, the integration of artificial intelligence (AI) with vision systems has transformed traditional automation workflows. Robots are now capable of real-time decision-making, significantly improving efficiency and reducing errors compared to conventional sensor-based approaches. The comparative merits of each technology highlight the importance of selecting the right solution to meet specific operational requirements in manufacturing and logistics, ultimately driving productivity and innovation in the workforce.

Implementing vision guided robotics (VGR) solutions offers transformative potential for automation, yet it also presents a set of unique challenges that organizations must navigate. One significant consideration is the integration of complex vision systems with existing automation frameworks. Ensuring compatibility between robotic hardware and software requires careful planning and expertise. Organizations may face difficulties related to data processing speeds and the quality of visual inputs, which can directly affect the efficiency and performance of VGR systems. Moreover, the installation of cameras and sensors in production environments might necessitate infrastructure changes, leading to higher initial costs.

Training personnel to operate and maintain VGR systems is another crucial aspect that can impact implementation success. Workers must understand how to interpret visual data and respond to automated decisions made by the robotic systems. This often involves a learning curve and could potentially slow down operations during the transition phase. Additionally, ongoing technical support and system updates are essential for keeping the systems functioning optimally, which can also strain resources. Companies must balance these factors carefully to ensure that the benefits of vision guided robotics outweigh the challenges encountered during adoption.

| Solution | Key Features | Applications | Challenges | Considerations |

|---|---|---|---|---|

| Robotic Inspection System | High precision, real-time processing | Quality control, defect detection | Lighting variations, complex environments | Calibration, maintenance requirements |

| Automated Packaging System | Flexible configurations, adaptive control | Food processing, electronics | Sensitivity to product variations | Integrating with existing systems |

| Collaborative Robots (Cobots) | Safety features, easy programming | Assembly lines, handling | Limited payload capacity | Workplace layout optimization |

| Vision-Guided Picking | 3D vision capabilities, fast identification | E-commerce, warehousing | Complex item shapes | System integration complexity |

| Laser-Based Measurement Systems | High accuracy, contactless operation | Metrology, surface profiling | Cost of equipment | Environmental considerations |

The integration of vision-guided robotics (VGR) is set to revolutionize automation, paving the way for more intelligent and adaptable systems. As industries increasingly seek to enhance efficiency and accuracy, advancements in machine vision technologies have become crucial. Future trends indicate a shift towards enhanced artificial intelligence (AI) capabilities, enabling robots to not only perceive their environment but also to learn from it. This means that VGR systems will increasingly leverage deep learning algorithms to adapt to varying conditions and improve their performance over time, leading to a significant reduction in operational downtime and increased productivity.

Another emerging trend is the convergence of VGR with Internet of Things (IoT) technologies. This integration allows for real-time data collection and analysis, enabling robots to make informed decisions autonomously. Furthermore, as VGR systems become more interconnected, they can collaborate seamlessly with other automated processes, creating a cohesive ecosystem where human and machine interactions are optimized. The use of cloud computing will also facilitate remote monitoring and management, allowing for enhanced scalability and flexibility in operations. These developments promise not only to transform traditional manufacturing processes but also to expand the scope of automation into sectors previously considered challenging for robotic integration.

This chart illustrates the adoption rate of vision-guided robotics solutions in automation over the past five years. The increasing trend indicates a significant shift towards automation integration, showcasing how these technologies are transforming industries.