In the fast-paced world of packaging, the efficiency of operations often hinges on the equipment used. One pivotal technology that has transformed the industry is form and fill machines. As noted by industry expert Dr. Linda Chen, "The integration of form and fill machines into production lines not only streamlines processes but also enhances product integrity and reduces waste." This highlights the critical role these machines play in modern packaging solutions.

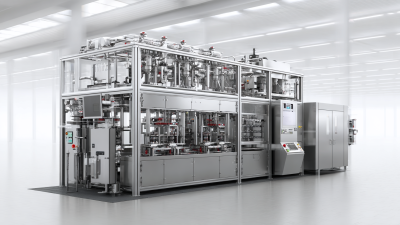

Form and fill machines automate the process of creating containers and filling them with products, thus driving productivity and ensuring consistency. With a growing demand for efficient packaging solutions across various sectors, the versatility and reliability of these machines have become more important than ever. Companies are increasingly seeking innovative technologies that not only meet their operational needs but also comply with environmental standards.

As businesses look to improve their packaging processes, understanding the best practices and latest advancements in form and fill technology is essential. In this exploration, we will delve into the most effective form and fill machines available, highlighting their features, capabilities, and the impact they have on efficiency and sustainability within the packaging industry.

The form and fill machines play a critical role in the packaging industry by streamlining the process of packaging a wide variety of products across several sectors, including food, pharmaceuticals, and consumer goods. These machines automate the process of creating packaging from a roll of material, filling it with the desired product, and sealing it, which significantly reduces time and labor costs. According to a report by Smithers Pira, the global market for automatic packaging machinery is projected to reach over $50 billion by 2025, illustrating the growing demand for efficient packaging solutions.

Form and fill machines come equipped with advanced technologies, such as high-speed filling and automatic sealing, which enhance productivity and maintain product integrity. A 2022 report by MarketsandMarkets highlighted that the form-fill-seal segment within the packaging machinery market is expected to witness a CAGR of 4.8% from 2021 to 2026. This growth is driven by the rising requirement for sustainable packaging solutions and the increasing frequency of packaged food consumption. Additionally, the versatility of form and fill machines enables manufacturers to cater effectively to diverse packaging needs, whether it’s for liquid, powder, or solid products, thus bolstering operational efficiency and ensuring product quality.

Form and fill machines are essential in modern packaging processes, offering a streamlined approach to packaging various products. These machines come in several types, each tailored to specific packaging needs, significantly enhancing efficiency and reducing labor costs. According to the “Global Packaging Machinery Market” report by Industry Research, the market for these machines is expected to grow by over 6% annually, driven by the demand for automation in the packaging industry. This growth reflects a critical shift toward more sophisticated and efficient packaging solutions.

Among the various types of form and fill machines, vertical and horizontal form fill seal machines (VFFS and HFFS) are the most prevalent. VFFS machines are particularly advantageous for packaging powders, granules, and liquids, allowing for rapid cycle times and high output efficiency, while HFFS machines excel in packaging bulkier items with intricate designs. The choice between these types depends on the specific requirements of the product being packaged, with each type offering unique advantages in speed, flexibility, and product handling. Research indicates that over 50% of companies utilizing form and fill technology report improvements in production speed and reduced material waste, making these machines a smart investment for manufacturers aiming to enhance their packaging lines.

| Machine Type | Key Features | Material Compatibility | Speed (packs/min) | Typical Usage |

|---|---|---|---|---|

| Vertical Form Fill Seal (VFFS) | Compact design, modular components | Granules, powders, liquids | 30-200 | Snacks, granulated foods |

| Horizontal Form Fill Seal (HFFS) | Versatile, user-friendly | Pouches, bags, flow packs | 50-150 | Meat, produce, bakery items |

| Fill and Seal Machines | High accuracy filling, various seal methods | Liquids, gels, pastes | 20-100 | Cosmetics, pharmaceuticals |

| Aseptic Fill Seal Machines | Sterile environment, precise controls | Dairy, juice, medical | 30-120 | Beverages, sensitive products |

| Multi-lane Fill Seal Machines | High output, space-efficient | Snacks, dried fruits | 100-300 | High volume production lines |

When selecting a form and fill machine for your packaging needs, several factors play a crucial role in ensuring optimal efficiency and effectiveness. First, consider the type of products you will be packaging. Different machines cater to various shapes, sizes, and materials. It's vital to choose a machine that can handle the specific characteristics of your products to maintain quality during the filling process.

Another critical factor is the speed and output of the machine. Assess your production requirements and determine the volume of products you need to package within a specific timeframe. Machines with adjustable speed settings can provide added flexibility and optimize productivity according to your operational needs.

Tips: Before making a purchase, conduct thorough research and consult industry experts to gather insights on your options. Additionally, evaluate the machine's maintenance requirements to ensure you can sustain its performance over time without incurring unexpected costs. Furthermore, consider automation features that enhance efficiency—these can save labor costs and reduce the risk of human error in high-volume production environments.

Implementing form and fill machines in packaging processes offers a multitude of benefits that significantly enhance operational efficiency. One of the primary advantages is the automation of packaging tasks, which minimizes manual labor and reduces the probability of human error. These machines are designed to handle the entire packaging process, from forming the package to filling it with the product, ensuring consistency and precision in every cycle. This level of automation can lead to substantial time savings and increased output, making it ideal for businesses looking to scale their production capabilities.

Moreover, form and fill machines contribute to cost-effectiveness by optimizing material usage and minimizing waste. By accurately measuring and dispensing products, these machines ensure that packaging materials are used efficiently, which reduces overall packaging costs. Additionally, their ability to operate at high speeds means that companies can meet consumer demands more quickly without compromising quality. This seamless integration of technology not only streamlines operations but also enhances product integrity and shelf life, ultimately benefiting both manufacturers and consumers alike.

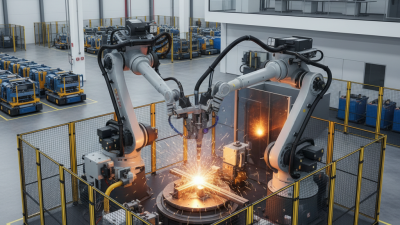

As the packaging industry evolves, form and fill technology stands at the forefront of efficient packaging solutions, embracing automation and innovation. According to a recent report by Smithers Pira, the global market for form-fill-seal technology is projected to grow at a CAGR of 4.7%, reaching approximately $18.8 billion by 2025. This growth is driven largely by the increasing demand for speed and efficiency in packaging processes across various sectors, including food and beverage, pharmaceuticals, and consumer goods.

Future trends in form and fill technology indicate a significant shift towards smart packaging systems that integrate IoT (Internet of Things) capabilities. These systems will not only enhance operational efficiency but also enable real-time data collection and analytics, thereby improving supply chain transparency. For instance, a study by the Packaging Machinery Manufacturers Institute highlights that 32% of manufacturers are already implementing IoT-enabled machinery, which can lead to a 20% reduction in downtime. Additionally, biodegradable and sustainable packaging solutions are gaining traction, aligning with consumer preferences for environmentally friendly products and regulatory pressures. The trend towards sustainability, coupled with advancements in automation, will likely define the next era of form and fill technology, ensuring that packaging processes are not only efficient but also environmentally responsible.