In today's fast-paced business environment, efficiency and productivity are paramount, particularly in the packaging sector. The rise of automation packaging has revolutionized how companies approach their packaging needs, streamlining operations and significantly reducing labor costs. Noted automation packaging expert, Dr. Emily Thompson, emphasizes the transformative impact of this technology, stating, "Automation packaging not only accelerates production rates but also enhances quality control, making it an indispensable asset for modern businesses."

As organizations seek to optimize their supply chains, the integration of automation packaging solutions emerges as a crucial strategy. By automating packaging processes, businesses can minimize human error, improve safety, and maintain consistency in output. This evolution is not merely about adopting new technology; it's a comprehensive approach to enhancing operational efficiency and meeting ever-growing customer expectations.

The following discussion will explore the ten best automation packaging solutions available today that can significantly boost your business efficiency. These solutions not only represent technological advancement but also serve as key drivers for competitive advantage in an increasingly automated world. Embracing these innovations can position companies at the forefront of their industries, ready to face the challenges and opportunities of the future.

When searching for automation packaging solutions, several essential features can significantly enhance your business efficiency. Firstly, flexibility is a paramount characteristic to consider. An ideal automation system should be adaptable to different product sizes, shapes, and packaging styles, ensuring that it can accommodate changes in your product line without necessitating a complete overhaul. This flexibility minimizes downtime and maximizes productivity by allowing you to respond swiftly to market demands.

Another crucial feature is the integration capabilities of the packaging solution. A system that can seamlessly connect with your existing machinery and production lines can streamline operations considerably. This integration not only facilitates data sharing across platforms but also allows for real-time monitoring, leading to improved decision-making and reduced operational costs. Moreover, an automated packing solution equipped with advanced analytics can help identify bottlenecks or inefficiencies in the process, enabling continuous improvement in your packaging operations.

Lastly, consider the level of automation offered. Solutions with varying degrees of automation—ranging from semi-automated systems to fully automated lines—can allow businesses to scale up their operations as needed. Choosing a solution that offers modular components can provide the scalability required to grow alongside your business, ensuring that investment in automation pays off in the long run. By focusing on these key features, companies can select the right automation packaging solution that not only boosts efficiency but also supports sustainable growth.

Automation packaging technologies have become a vital aspect across various industries, providing significant efficiency gains and cost reductions. In food and beverage, for instance, packaging automation has been shown to reduce labor costs by up to 30%, according to Industry Research reports. Technologies such as robotic arms and automated carton fillers streamline the packaging process, reducing human error and increasing output rates. This is particularly crucial in industries where speed and accuracy are paramount to meet consumer demand.

In the pharmaceutical sector, automation solutions like blister packaging machines and automated labeling systems are essential for compliance and traceability. A study by Pharma IQ highlights that nearly 42% of pharmaceutical companies are investing in packaging automation to enhance production speeds and improve safety standards. Automated systems can ensure precise dosing and packaging, crucial for maintaining the integrity of sensitive products. As regulations grow stricter, such technologies not only bolster efficiency but also ensure adherence to safety protocols, ultimately safeguarding public health.

Ultimately, the integration of automation packaging technologies serves as a transformative strategy for businesses across multiple sectors. The drive towards automation is underscored by industry forecasts, which predict a compound annual growth rate (CAGR) of 14.7% in the global packaging automation market by 2027, emphasizing a clear trend toward increased operational efficiency and innovation in packaging processes.

This chart illustrates the effectiveness of various automation packaging solutions across different industries, showcasing how these technologies enhance overall efficiency.

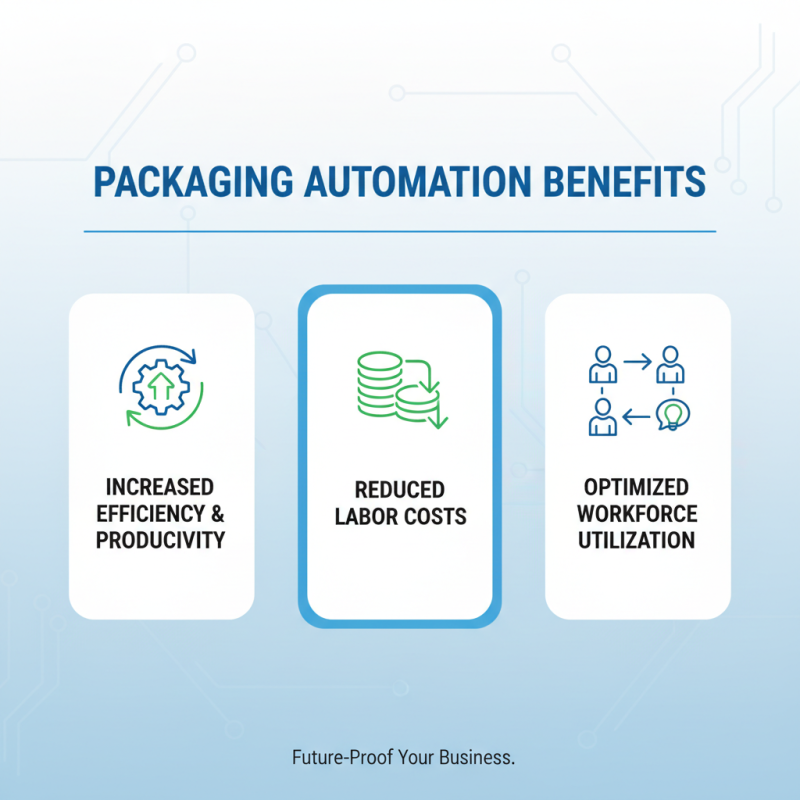

Implementing automation in packaging processes can significantly enhance business efficiency and productivity. One of the major benefits is the reduction in labor costs. Automated packaging systems streamline the workflow, minimizing the need for manual intervention. With machines handling repetitive tasks, businesses can allocate their human resources to more complex and value-added activities, thereby optimizing workforce utilization.

Moreover, automation improves the accuracy and consistency of packaging operations. Automated machines are designed to perform tasks with precision, which reduces the likelihood of errors associated with manual packaging. This not only enhances product quality but also boosts customer satisfaction by ensuring that products are packaged correctly and uniformly. Additionally, automated systems can operate continuously, leading to increased throughput and faster turnaround times, which are essential for meeting growing market demands.

Another significant benefit of packaging automation is the ability to gather and analyze data in real time. Automated systems can monitor various metrics, providing insights into performance, efficiency, and potential bottlenecks. This data-driven approach enables companies to make informed decisions, optimize their packaging processes, and implement continuous improvements, ultimately leading to a more resilient and responsive business model.

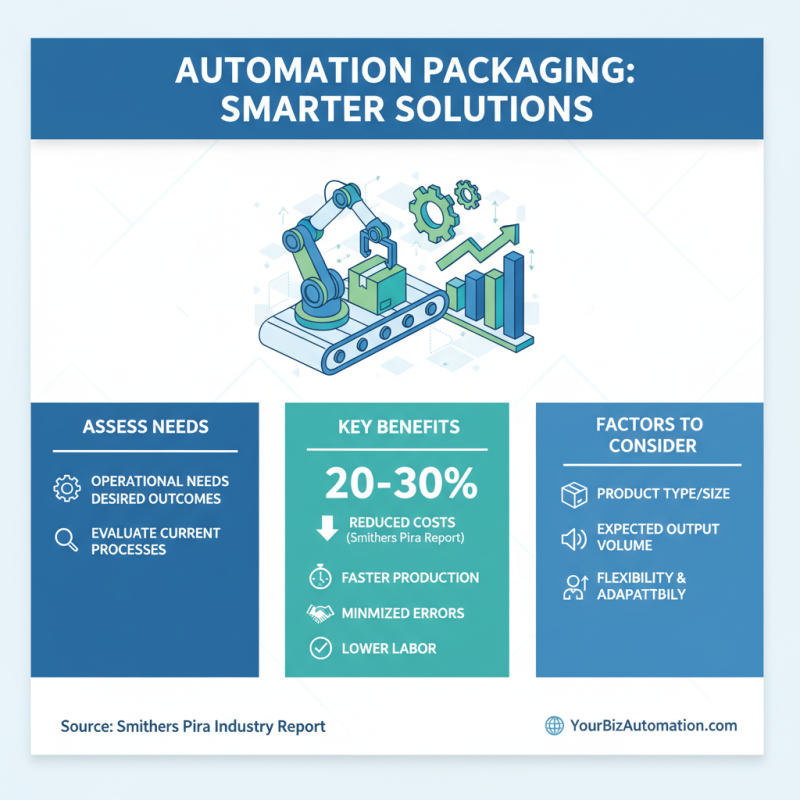

When selecting the right automation packaging solution for your business, it is essential to assess your specific operational needs along with the desired outcomes. An industry report by Smithers Pira indicates that automation can reduce packaging costs by an average of 20-30%, significantly impacting the bottom line. Businesses should first evaluate their existing packaging processes and identify areas where automation could enhance efficiency, such as reducing labor costs, minimizing errors, and speeding up production time. Key factors to consider include the type of products being packaged, the expected output volume, and the flexibility required to handle variations in product sizes and types.

Another critical aspect is understanding the technological compatibility of prospective solutions. According to a survey by PMMI, over 70% of packaging professionals emphasize integration with existing systems as a top priority when investing in new automation technology. It is crucial to choose a solution that seamlessly connects with your current machinery and software to maximize ROI. Moreover, examining case studies of similar businesses that have implemented automation can provide valuable insights into potential challenges and benefits, thus aiding in making an informed decision that aligns with overall business goals.

As automation packaging continues to evolve, businesses are increasingly adopting innovative solutions to not only streamline their processes but also enhance overall efficiency. One significant trend is the integration of artificial intelligence (AI) and machine learning (ML) into packaging operations. By leveraging these technologies, companies can optimize production schedules, predict maintenance needs, and minimize downtime. This predictive capability allows businesses to allocate resources more effectively, ultimately leading to cost savings and improved productivity.

Another notable trend is the rise of smart packaging solutions. These advancements include the use of IoT devices that monitor and transmit data throughout the packaging process. By enabling real-time tracking and analysis, manufacturers can quickly identify bottlenecks and make informed decisions to enhance efficiency. Moreover, sustainability has become a key focus in automation packaging, with many companies looking to adopt eco-friendly materials and processes. This not only meets consumer demand for greener practices but also helps businesses reduce waste and comply with stricter regulations, positioning them favorably in a competitive market.

| Solution Name | Key Features | Efficiency Gains | Ideal Industries | Future Trends |

|---|---|---|---|---|

| Automated Carton Sealer | Fast sealing speed, adjustable height | Increase productivity by 25% | Consumer Goods, Electronics | Integration with IoT |

| Robotic Palletizer | Flexible design, can handle various loads | Reduces labor costs by 30% | Food & Beverage, Pharmaceuticals | AI for improved performance |

| Stretch Wrapper | Consistent tension control, easy to operate | Saves material costs by 15% | Manufacturing, Wholesale | Smart wrapping solutions |

| Labeling Machine | High-speed labeling, customizable formats | Increases labeling efficiency by 40% | Cosmetics, Food | Automated label design |

| Filling Machine | Accurate filling, various container types | Reduces filling errors by 20% | Beverage, Chemical | Integration with production systems |

| Case Erector | Fast case forming, compact design | Boosts case packing speeds by 30% | E-commerce, Pharmaceuticals | Customizable for varied sizes |

| Shrink Wrapper | Maintains product integrity, energy-efficient | Improves packaging speed by 25% | Dairy, Bakery | Sustainable materials usage |

| Conveyor System | Modular design, various speeds | Increases throughput by 35% | All Industries | Real-time tracking systems |

| Batching Machine | Precision batching, multi-ingredient handling | Decreases waste by 10% | Food Processing, Cosmetics | Smart batch control |