The automation of packaging lines is transforming the production landscape. According to a recent report by MarketsandMarkets, the global automated packaging market is expected to reach $29 billion by 2026. This growth indicates a strong demand for efficient production technologies. The industry is evolving rapidly, driven by innovations in robotics and AI.

Experts highlight the importance of optimizing these automated packaging lines. James Smith, a leading analyst in the field, states, "The right technology can dramatically increase throughput." However, challenges still exist. Many companies struggle with integration and scalability. The effectiveness of these systems hinges on how well they blend with existing workflows.

Beyond efficiency, there is a need for companies to address sustainability. Automatic systems can reduce waste. Yet, many still rely on outdated practices. As we advance towards 2026, the quest for improved automated packaging line technologies will continue. The success of this evolution will depend on industry players' willingness to adapt and innovate.

The future of packaging line technologies is fascinating. As industries look for more efficient solutions, innovation is key. New software and robotics enhance precision in packaging. Automation reduces human error. This leads to faster production cycles, but not without challenges.

One prominent advance is the use of artificial intelligence. AI systems analyze production data in real time. They can predict potential bottlenecks and downtime. This ensures smoother operations, but companies must adapt their workforce to this change. Training becomes essential. Finding the right balance of AI and human skills is crucial.

Sustainability is another focus. Eco-friendly materials are gaining traction. Innovative packaging machines are designed for quicker changeovers. This allows companies to switch between products easily. However, the initial costs of these technologies can be high. Many businesses need to reflect on their budget before investing. The road ahead is filled with possibilities and critical decisions.

Automated packaging systems are crucial for modern manufacturing. They enhance productivity while reducing labor costs. According to industry reports, about 70% of companies see increased efficiency after implementing these systems. Key components include programmable logic controllers (PLCs) and vision systems. These tools help in monitoring quality and speed during production.

Another essential element is the integration of robotics and artificial intelligence. Robots can perform repetitive tasks and adapt to fluctuating production demands. In a recent survey, 65% of manufacturers reported lower error rates with robotic systems in place. However, the transition to automation isn't without challenges. Many facilities struggle with workforce retraining and system integration.

Moreover, maintaining equipment is vital for continuous operation. Downtime can lead to significant losses. A study indicated that around 40% of unplanned downtime is due to equipment failure. Companies must regularly assess their machinery and invest in predictive maintenance. Embracing these systems requires careful planning and a willingness to adapt.

| Technology Component | Description | Efficiency Benefits | Examples of Applications |

|---|---|---|---|

| Robotic Arm | Automates the handling and packing of products | Increases speed and reduces manual labor | Palletizing, case packing |

| Conveyor Systems | Transports products through different packaging stages | Streamlines workflow and minimizes downtime | Between production and packaging areas |

| Automated Weighing Systems | Ensures accurate measurement of products | Reduces errors and improves consistency | Food packaging, pharmaceuticals |

| Labeling Machines | Applies labels onto products and packages | Enhances brand presentation and compliance | Beverage, cosmetics industries |

| Vertical Form Fill Seal (VFFS) | Forms, fills, and seals packages automatically | Maximizes efficiency for bulk products | Snack foods, grains |

The impact of AI and robotics on packaging line efficiency is revolutionary. Automated systems can reduce labor costs by 30%, according to recent industry reports. They enhance productivity and ensure a consistent quality of packaging. Many companies now integrate AI to predict bottlenecks. This proactive management fosters smooth operations.

Tips: Invest in training your team. Understanding new tech is vital. Also, analyze your workflow regularly. Look for areas needing improvement.

Robotic systems handle repetitive tasks effectively. They minimize human errors and work tirelessly. However, the implementation of such systems can be complex. Integrating new technologies requires careful planning and significant investment. Consider your company’s specific needs before proceeding.

Finally, AI's role extends beyond automation. Data collected from packaging lines provides insights. These insights inform strategies for further growth and reduce waste. Nevertheless, companies must remain adaptable as technology evolves. Always be ready to reassess your systems.

The push for sustainability in automated packaging technologies is reshaping the industry. Many companies aim to reduce their environmental footprint while enhancing efficiency. According to a recent report, 70% of manufacturers are investing more in sustainable packaging solutions. This shift includes using recyclable materials and minimizing waste during production.

While automated systems do increase speed, not all solutions are eco-friendly. Some still rely on plastic that isn't easily recycled. This contradiction requires careful analysis. Businesses must evaluate the entire supply chain. Are they really reducing waste? It’s a challenge that calls for innovation.

**Tip:** Consider switching to biodegradable materials. They can offer good performance with less environmental impact.

Moreover, energy consumption in packaging processes is under scrutiny. A study highlights that 40% of energy used in production accounts for packaging processes. Finding ways to improve energy efficiency is crucial. Can automation save more energy long-term? This remains an open question for many firms.

**Tip:** Look into energy-efficient machinery options. They can reduce operational costs.

As sustainability practices evolve, the industry must adapt. Balancing efficiency and eco-friendliness is vital. It's a complex task but worth the effort for a greener future.

The future of packaging automation is fascinating and complex. Innovations are making production lines faster and more efficient. For instance, robotic systems are gaining traction. They can handle delicate items, reducing the risk of damage. However, not every automation solution fits every situation. Businesses often struggle to find the right technology for their needs.

Another significant trend is the integration of artificial intelligence. AI can predict machine failures before they happen. This proactive approach minimizes downtime. Yet, training staff to work alongside AI remains a challenge. Companies need skilled workers who can manage these advanced systems efficiently.

Sustainability is also a concern. As automation grows, we must consider its environmental impact. Automated packaging should focus on reducing waste. However, achieving a balance between efficiency and sustainability can be tricky. The industry must continually innovate, reflecting on its practices to make meaningful changes. These trends indicate a pivotal shift in how we think about packaging processes.

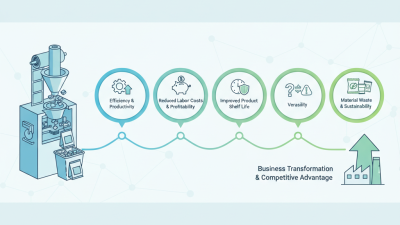

This chart illustrates the projected adoption rates of various automated packaging technologies in 2026, showcasing trends that enhance production efficiency.