The packaging industry has seen significant advancements in technology over the past few decades, and one of the standout innovations is the vertical form fill and seal machine. This equipment not only streamlines the packaging process but also enhances efficiency and reduces operational costs. As industry expert, Dr. Julia Kensington, a prominent figure in packaging technology, noted, “The vertical form fill and seal machine is a game-changer, offering unmatched versatility and speed for various packaging needs.”

In today’s fast-paced market, businesses are increasingly seeking reliable solutions that can adapt to changing consumer demands while maintaining high-quality standards. The vertical form fill and seal machine meets these requirements by allowing manufacturers to package a wide variety of products, from powders to liquids, in a consistent, visually appealing format. This flexibility ensures that companies can respond swiftly to market trends without sacrificing quality or productivity.

As we delve into the top benefits of using vertical form fill and seal machines for packaging, it becomes clear that these machines provide a multitude of advantages, including increased efficiency, lower labor costs, and improved product shelf life. By incorporating this technology, businesses can not only streamline their operations but also position themselves for future growth in a competitive landscape.

Vertical Form Fill and Seal (VFFS) machines are an essential component in modern packaging solutions, offering streamlined processes and efficiency. One of the key features of these machines is their ability to form pouches directly from a roll of film, which minimizes material waste and maximizes production speed. This feature allows for various pouch sizes and shapes to be created, accommodating a wide range of products—from granular materials to liquids—making them highly versatile in different industries.

Another notable feature of VFFS machines is the integration of advanced control systems that enhance automation and precision. These machines typically come equipped with user-friendly interfaces that allow operators to easily adjust settings such as fill volumes, sealing temperatures, and speeds. Additionally, many models incorporate sensors for quality control, ensuring that each pouch is filled accurately and sealed securely, thereby reducing the risk of contamination and extending product shelf life. This combination of adaptability and precision makes VFFS machines a preferred choice for manufacturers aiming to optimize their packaging operations.

Vertical Form Fill and Seal (VFFS) machines are revolutionizing packaging processes by significantly enhancing production efficiency. One of the primary advantages lies in their ability to automate multiple stages of the packaging process, combining forming, filling, and sealing into a single continuous operation. This automation reduces the time and labor required to package products, allowing companies to increase output without sacrificing quality. The speed at which VFFS machines operate means that businesses can respond more rapidly to market demand, leading to improved customer satisfaction and reduced storage costs.

Moreover, VFFS machines are versatile in their application, catering to a wide range of product types, from solids to liquids and powders. This flexibility not only streamlines production by accommodating various products within the same packaging line but also minimizes the need for multiple machines, which can take up valuable floor space and increase maintenance requirements. As a result, companies can achieve greater operational efficiency, ultimately enhancing their competitiveness in a fast-paced market.

The reliable performance and reduced downtime of modern VFFS systems further contribute to a smoother production flow, making them an essential investment for any packaging operation seeking to optimize efficiency.

The adoption of Vertical Form Fill and Seal (VFFS) machinery has proven to be a cost-effective solution in the packaging industry, significantly impacting operational efficiency and overall production costs. According to a recent industry report by Smithers Pira, companies utilizing VFFS technology can reduce their packaging expenses by up to 30%. This reduction is primarily attributed to decreased labor costs, as these machines automate multiple processes—forming, filling, and sealing—thereby minimizing the need for manual intervention.

Moreover, the efficiency of VFFS machines often leads to a faster production rate, which translates into higher output without a proportional increase in overhead costs. Data from the Packaging Machinery Manufacturers Institute indicates that the average output of VFFS machinery can reach 200 to 500 bags per minute, whereas traditional methods may lag significantly behind. In addition to labor and speed efficiencies, VFFS systems also optimize material usage, resulting in less waste; an important aspect, given the rising costs of raw materials. By implementing VFFS technology, companies can not only improve their bottom line but also enhance sustainability efforts by using resources more judiciously.

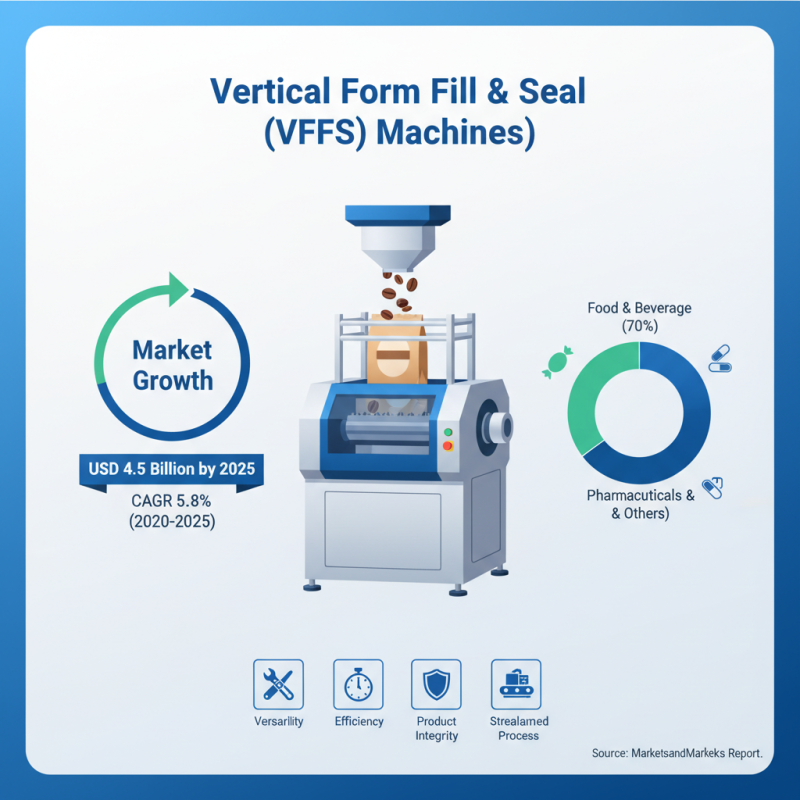

Vertical Form Fill and Seal (VFFS) machines play a crucial role in the packaging landscape across various industries. These machines are particularly favored for their versatility and efficiency, allowing businesses to package products ranging from food items to pharmaceuticals. According to a report by MarketsandMarkets, the global market for VFFS machines is projected to reach USD 4.5 billion by 2025, growing at a CAGR of 5.8% from 2020. This growth is largely driven by the food and beverage sector, where VFFS systems streamline the packaging process while maintaining product integrity.

In the food industry, VFFS machines are indispensable for packaging snacks, grains, and ready-to-eat meals. The ability to create barrier seals around products helps extend shelf life and ensures food safety. Additionally, sectors such as pharmaceuticals and personal care are increasingly adopting VFFS technology to package powders, liquids, and gels, ensuring compliance with stringent regulations while enhancing productivity. A key advantage is the reduction in packaging waste, as these machines are designed to optimize material usage, aligning with sustainability trends that are vital for modern consumers. As industries continue to evolve, the adoption of VFFS machines will likely expand, reflecting their integral role in efficient and reliable packaging solutions.

The choice of packaging method can significantly influence production efficiency and product preservation. Vertical Form Fill and Seal (VFFS) machines offer distinct advantages over traditional packaging techniques, such as horizontal wrapping and manual sealing. According to a recent market report by Smithers Pira, the VFFS market is expected to grow at a compound annual growth rate (CAGR) of 4.5% through 2027, reflecting a shift towards automation and efficiency in packaging processes. One key benefit of VFFS is its ability to handle a variety of materials and sizes, making it ideal for industries such as food, pharmaceuticals, and personal care.

When compared with other methods, VFFS machines demonstrate superior speed and flexibility. A study by PMMI highlights that VFFS systems can pack products at speeds exceeding 100 packages per minute while ensuring precise fill volumes. In contrast, traditional methods like manual packaging often struggle to maintain such high throughput, causing bottlenecks in production. Additionally, VFFS machines reduce material waste through precise sealing and cutting techniques, contributing to a more sustainable packaging process. This aspect is increasingly important, as industry reports indicate that consumer preferences are shifting towards sustainable packaging solutions, further driving the adoption of VFFS technology.

| Feature | Vertical Form Fill and Seal | Other Packaging Methods |

|---|---|---|

| Speed of Packaging | High (up to 100 packs/min) | Moderate (20-60 packs/min) |

| Material Flexibility | Widely compatible (films, pouches) | Limited to specific materials |

| Cost Efficiency | Low ongoing costs | Higher maintenance costs |

| Ease of Operation | User-friendly | Requires specialized training |

| Space Requirement | Compact design | Larger footprint |

| Product Versatility | Suitable for various products | Limited to specific products |