In the rapidly evolving landscape of modern manufacturing, the integration of advanced technologies is paramount for achieving efficiency and precision. Among these innovations, the Lincoln robotic welder stands out as a game-changer that revolutionizes traditional welding methods. John Smith, a leading expert in robotic automation, emphasizes the significance of this technology, stating, "The adoption of Lincoln robotic welders not only enhances productivity but also ensures unmatched precision in every weld." This assertion underscores the pivotal role that Lincoln robotic welders play in streamlining manufacturing processes across various industries.

As manufacturers strive to remain competitive, the benefits of employing Lincoln robotic welders become increasingly apparent. From reducing operational costs to improving safety standards, these automated solutions are reshaping the way welding tasks are performed. By delving into the top ten advantages of utilizing Lincoln robotic welders, businesses can harness the full potential of automation, driving their production capabilities to new heights. There is no doubt that, as we explore these benefits, the impact of Lincoln robotic welders will be revealed as a cornerstone of modern manufacturing excellence.

In modern manufacturing, precision and consistency are paramount, especially in welding processes. Utilizing advanced robotic welders can significantly enhance the accuracy of welds, resulting in a superior quality product. These machines are designed to execute repetitive welding tasks with intricate precision, minimize variations, and drastically reduce the likelihood of human error. As a result, manufacturers can achieve tighter tolerances and better fitment of components, ultimately leading to improved performance and reliability of the finished products.

To maximize the benefits of robotic welding, companies should ensure that their operators are well-trained in programming and maintenance. Regular calibration and updates to the welding parameters can help maintain the optimal performance of robotic systems. Additionally, integrating real-time monitoring systems can provide insights into weld quality, allowing manufacturers to quickly address any deviations before they result in significant defects.

Moreover, investing in advanced welding technologies can provide flexibility in production. Companies can easily switch between different welding tasks by reprogramming the robotic systems, allowing for high adaptability in meeting diverse production needs. This not only saves time and resources but also enhances the overall efficiency of the manufacturing process.

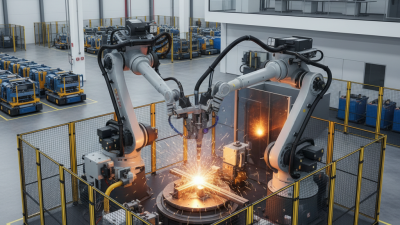

In the realm of modern manufacturing, automation has emerged as a key driver of enhanced productivity and efficiency. Utilizing advanced robotic welders allows manufacturers to streamline their operations, reducing the time spent on repetitive tasks. According to a recent report by the International Federation of Robotics, companies that adopted automation saw productivity increases of up to 30%. This significant boost stems from the ability of robotic systems to operate continuously, minimizing downtime and maximizing output.

Additionally, the integration of robotic welding solutions leads to improved precision and consistency in the manufacturing process. A comprehensive study by the American Welding Society found that automated welding applications can achieve accuracy levels of up to 99%, drastically reducing the margin of error typically associated with manual processes. This not only enhances product quality but also minimizes waste, which is crucial in today’s cost-sensitive market. Furthermore, the ability to quickly adapt to changing production requirements ensures that manufacturers can remain competitive and responsive to customer needs. As the manufacturing landscape continues to evolve, embracing automation through robotic welding is becoming increasingly essential for operational success.

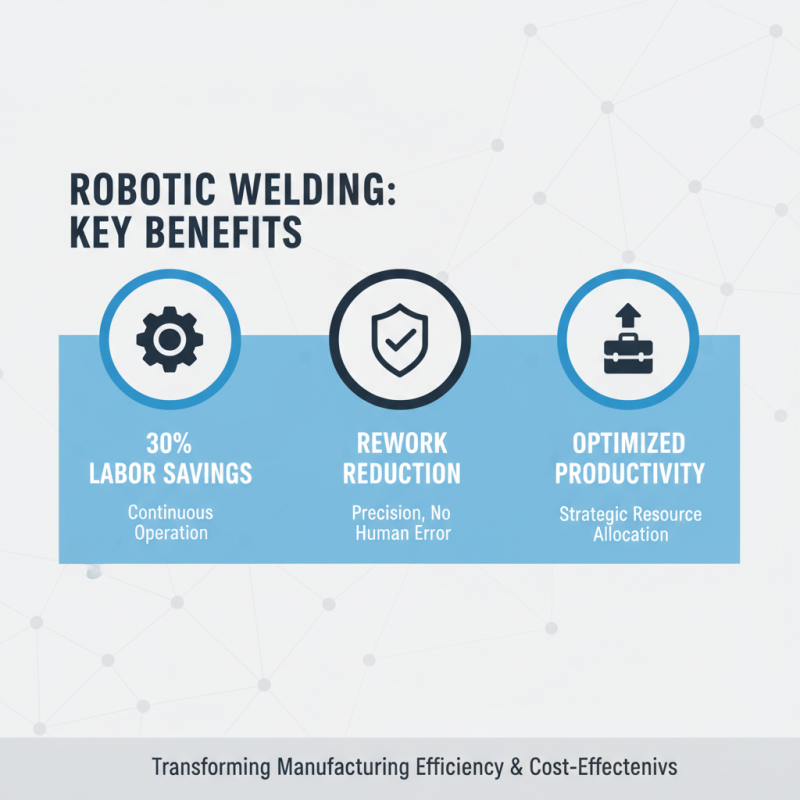

Investing in robotic welding technology is not just advantageous for operational efficiency, but it also offers significant cost-effectiveness that can transform manufacturing processes. According to a recent industry report, facilities that implement robotic welders can experience labor savings of up to 30%, as these machines are designed to work continuously and with precision. The elimination of human error leads to a reduction in rework costs, which can average around 20% of total manufacturing expenses. By automating welding tasks, companies can reallocate human resources to more strategic projects, optimizing overall workflow and productivity.

Tip: When considering the introduction of robotic welders, conduct a thorough analysis of your current welding operations to identify specific areas where automation could yield the highest returns. This evidence-based approach will ensure that your investment aligns with your operational goals and financial expectations.

Additionally, the initial investment in robotic welders can often pay for itself within a few years through increased throughput and reduced material costs. A study by the National Association of Manufacturers highlights that integrating robotics can boost production output by over 50%, allowing manufacturers to meet market demands more effectively. The long-term benefits far outweigh the upfront costs, making it a strategic move for companies aiming to enhance their competitive edge in the modern manufacturing landscape.

Tip: Be sure to evaluate the total cost of ownership (TCO) when budgeting for robotic welders, including maintenance, training, and potential software upgrades. This holistic view can help secure a clearer understanding of your long-term investment returns.

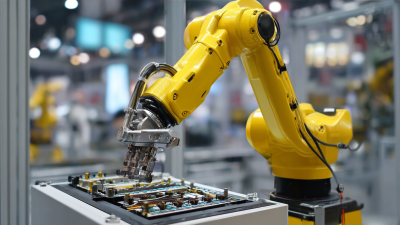

Modern manufacturing demands flexibility and adaptability to meet the ever-evolving market needs, and robotic welders have emerged as a pivotal solution. These advanced systems are designed to handle a wide variety of materials and configurations, allowing manufacturers to easily pivot between different projects without extensive downtime. Whether it’s for small-scale prototypes or large-scale production runs, robotic welders can be programmed to accommodate diverse welding techniques and specifications. This versatility enables manufacturers to respond swiftly to custom orders while maintaining high standards of quality.

Moreover, the integration of advanced sensors and AI technology in robotic welding systems enhances their adaptability. These systems can automatically adjust parameters based on real-time feedback, ensuring optimal performance across different materials and styles. This capability not only streamlines production processes but also reduces the risk of errors associated with manual welding. As a result, manufacturers can achieve greater efficiency and consistency, ultimately leading to improved productivity and lower operational costs. With the ability to easily reconfigure for different tasks, robotic welders stand out as essential tools for modern manufacturing environments.

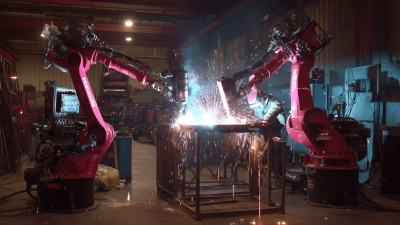

In modern manufacturing, the integration of advanced robotic welding systems has significantly enhanced safety measures across the production floor. Traditional welding processes often expose operators to hazardous fumes, intense heat, and potential accidents involving heavy machinery. By implementing robotic welding solutions, manufacturers can minimize these risks. Robots can operate in extreme environments, handling tasks that would otherwise place human workers in perilous situations, such as in high-temperature zones or areas with toxic exposures.

Moreover, robotic welding setups are designed with built-in safety features, including emergency stop buttons, safety barriers, and sensor systems that detect human presence. These technologies ensure that the robots can operate efficiently while simultaneously protecting personnel from accidental injuries. The increased precision and consistency of robotic welds also reduce the chances of defective products, leading to fewer workplace incidents related to equipment failures or rework processes.

As a result, the overall safety and efficiency of the manufacturing environment are significantly enhanced, creating a more secure atmosphere for workers.