In today's fast-paced industrial landscape, the integration of technology into production processes has become not just a trend but a necessity. One of the most significant advancements in manufacturing is the implementation of an automated packaging line. According to a report by ResearchAndMarkets, the global automated packaging market is projected to reach $79.8 billion by 2026, growing at a CAGR of 14.2%. This substantial growth highlights the increasing reliance of businesses on automation to enhance efficiency and effectiveness in their operations.

Automated packaging lines are transforming the way products are packed, moving beyond traditional manual methods. They offer a myriad of benefits, from increased speed and precision to reduced labor costs and minimized waste. A study by the National Institute of Standards and Technology (NIST) found that implementing automation in packaging processes can lead to a 20-25% increase in productivity, underscoring the tangible advantages for manufacturers looking to optimize their supply chains. This shift not only helps businesses meet the rising demand for quicker turnaround times but also enhances product quality and consistency, ensuring customer satisfaction.

As we delve into the top ten benefits of adopting an automated packaging line, it is crucial to understand how these systems can provide a competitive edge in an increasingly saturated market. By leveraging advanced technologies, companies can streamline their operations, adapt to market changes, and ultimately drive profitability.

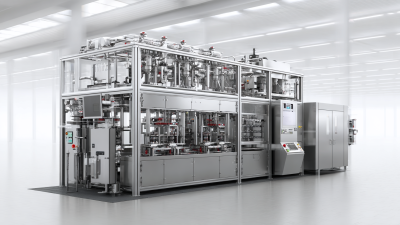

Automated packaging lines bring a multitude of advantages, particularly when it comes to enhancing efficiency. With the integration of advanced technologies such as layer gripping systems, these lines can now operate with remarkable precision and speed.

The increasing demand for streamlined processes within the packaging industry drives the adoption of automation, as businesses seek to reduce operational bottlenecks and improve workflow efficiency. The market for automated packaging solutions is expanding significantly; it is projected to grow from USD 75.54 billion to USD 140.82 billion by 2033, underscoring the growing recognition of efficiency as a key driver of success.

Moreover, automation fosters not only productivity but also flexibility in packaging operations. Companies can quickly adapt to changing consumer demands and market trends by utilizing smart artwork packaging solutions that minimize errors and accelerate production timelines.

The shift towards automation in the packaging sector is fueled by the need for greater efficiency throughout the supply chain, enabling organizations to maintain a competitive edge while managing costs effectively. As businesses continue to optimize their packaging processes, the benefits of automation, including enhanced efficiency, will only become more pronounced.

Enhanced product quality is one of the most significant advantages of incorporating an automated packaging line into your business operations.

Automation solutions streamline the packaging process by minimizing human error, ensuring that each product is consistently packed to the highest standards.

This consistency not only helps in maintaining the product integrity but also enhances its presentation, which is crucial for attracting customers and boosting sales.

Moreover, automated packaging systems come equipped with advanced quality control technologies, such as vision systems and sensors, that detect defects or inconsistencies in real-time.

This proactive approach allows companies to address issues immediately, reducing waste and ensuring that only top-quality products reach the market.

By investing in such automation solutions, businesses not only improve the overall reliability of their product offerings but also instill greater confidence in their customer base,

fostering brand loyalty and enhancing their reputation in a competitive market.

Automated packaging lines have revolutionized the way businesses approach efficiency and cost management. According to a report by MarketsandMarkets, the automated packaging market is expected to grow from $45.61 billion in 2020 to $77.30 billion by 2026, highlighting the increasing reliance on automation in the industry. One of the primary benefits of automated packaging is its potential for significant cost savings. By reducing manual labor, companies can save up to 30% on labor costs, enabling them to allocate resources more effectively and invest in innovation.

In addition to labor savings, automated packaging lines enhance resource optimization. A study published by the International Society of Automation revealed that companies using automated systems can achieve a 50% reduction in material waste. This is crucial in today’s market, where sustainability is becoming a key concern for consumers and businesses alike. Furthermore, automation minimizes errors and ensures consistent product quality, which helps in maintaining brand reputation and reducing costs associated with returns and rework. As businesses continue to embrace technology, the impact of an automated packaging line on cost savings and resource optimization cannot be overlooked.

| Benefit | Description | Expected Savings (%) |

|---|---|---|

| Increased Efficiency | Automated lines reduce packaging time and increase throughput. | 20-30% |

| Labor Cost Reduction | Less manual labor required leads to lower payroll expenses. | 15-25% |

| Reduced Material Waste | Precision packaging minimizes overuse of materials. | 10-20% |

| Enhanced Quality Control | Automated systems can consistently produce packages that meet quality standards. | 5-15% |

| Faster Return on Investment (ROI) | Initial cost offset by savings in labor and materials. | 25-35% |

| Scalability | Automatically adjust to higher production quantities without a need for additional labor. | Variable |

| Improved Safety | Reducing the need for manual handling lowers the risk of workplace injuries. | N/A |

| Streamlined Workflow | Automation increases speed and reduces bottlenecks in production. | 15-20% |

| Better Use of Space | Compact design of automated lines frees up valuable floor space. | N/A |

| Customer Satisfaction | Higher quality packaging leads to better product perception and customer experience. | N/A |

In today’s rapidly evolving market, flexible packaging options have become essential for businesses seeking to adapt to diverse consumer demands. According to a report from Smithers Pira, the global flexible packaging market is projected to reach $300 billion by 2024, showcasing the growing importance of this sector. Automated packaging lines offer a versatile solution that can easily switch between different packaging materials and styles, catering to a wide range of products. This adaptability enables businesses to respond promptly to market trends, such as sustainable packaging practices or unique design requirements.

Moreover, automated packaging technology not only enhances production efficiency but also allows for customization in packaging, which can significantly improve brand recognition and customer satisfaction. Research by the Flexible Packaging Association indicates that flexible packaging can reduce waste by 5-10% compared to rigid packaging formats, providing economic and environmental benefits. By leveraging automated systems, companies can introduce customized packaging solutions that meet specific regulatory and consumer requirements while also optimizing their operations and reducing costs. This strategic shift is vital for staying competitive in an increasingly flexible and consumer-centric marketplace.

This chart illustrates the top ten benefits of implementing an automated packaging line in a business, highlighting various aspects that can improve efficiency and flexibility.

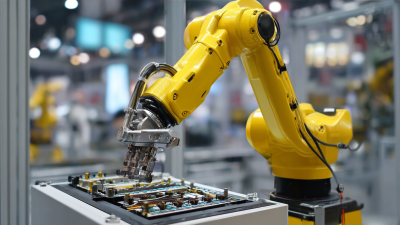

The integration of automated packaging lines is not just a trend but a significant advancement in workplace safety. A recent report highlights that companies implementing automation have observed a reduction in workplace injuries by over 25%. This shift not only minimizes human error but also enhances operational efficiency. For instance, advancements in robotics and automated machinery can handle heavy lifting and repetitive tasks, reducing the physical strain on workers, which is a leading cause of workplace injuries.

Moreover, organizations prioritizing psychological safety are also witnessing a drop in attrition rates, dipping to as low as 3%. Employees who feel secure in voicing their concerns contribute to a culture of safety and accountability, further reducing risks associated with labor-intensive operations. The adoption of technologies like VR for training in operations such as forklift handling reflects a proactive approach to safety, allowing workers to practice in a controlled environment while minimizing real-world risks. Thus, as automation evolves, it fundamentally transforms not only the efficiency of packaging operations but also significantly elevates workplace safety standards.