In today's fast-paced industrial landscape, the demand for efficiency and productivity has never been more critical. Automated packaging lines are emerging as a pivotal solution for modern industries, significantly optimizing operations and reducing costs. According to a report by Smithers Pira, the global market for automated packaging machinery is projected to reach $58.8 billion by 2026, with an annual growth rate of 4.4% from 2021. This reflects the increasing reliance of businesses on advanced technologies to enhance their packaging processes and maintain competitiveness.

The implementation of automated packaging lines not only streamlines production workflows but also minimizes human error and labor costs. A study from the Association for Packaging and Processing Technologies indicates that automation can improve packaging efficiency by up to 30%, leading to shorter lead times and faster time-to-market for products. As industries across sectors—from food and beverage to pharmaceuticals—embrace these innovations, the imperative for adopting automated packaging lines becomes increasingly apparent.

Such advancements are not merely enhancements; they are essential for businesses aiming to deliver superior products while ensuring sustainability and profitability in a rapidly evolving market.

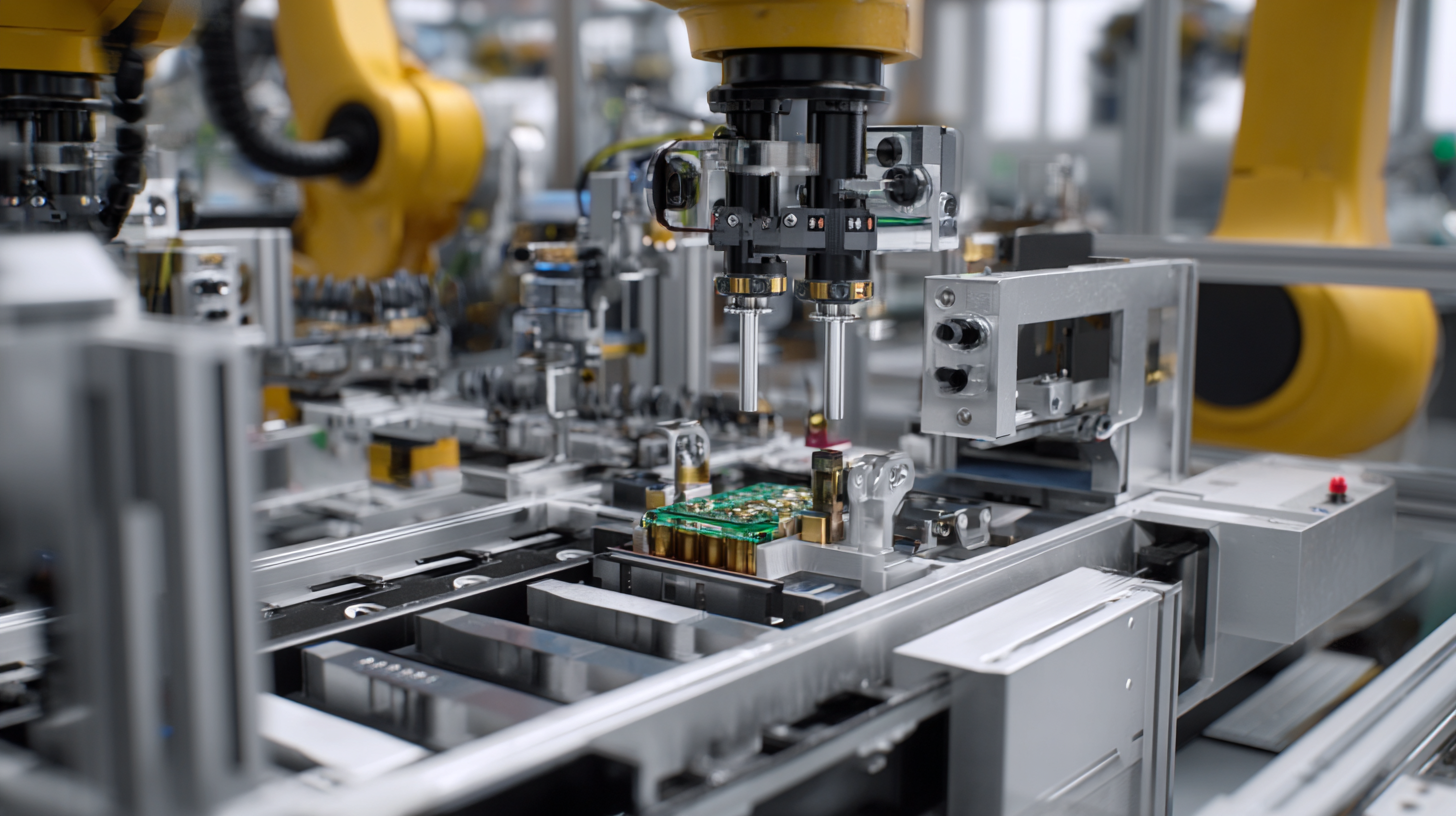

Automated packaging lines have transformed the way modern industries operate by enhancing speed, efficiency, and accuracy in the packaging process. These systems utilize advanced technology such as robotics, artificial intelligence, and sensors to streamline operations, reducing the need for manual labor and minimizing human error. Understanding the basics of these lines is crucial for any business looking to remain competitive in today's fast-paced market.

At the core of automated packaging lines are several key components, including conveyor systems, packaging machines, and control software. Each element plays a vital role in ensuring smooth workflow and consistency in output. For instance, conveyor systems facilitate the movement of products between different stages of packaging, while packaging machines can be programmed to handle various product types and sizes. Additionally, robust control software allows for real-time monitoring and data analysis, enabling industries to make informed decisions and optimize their processes continuously. Embracing these innovations not only boosts productivity but also enhances product quality and customer satisfaction.

This bar chart illustrates the efficiency improvements seen in modern packaging lines across various industries. Data is represented by the percentage increase in productivity after the implementation of automated packaging solutions.

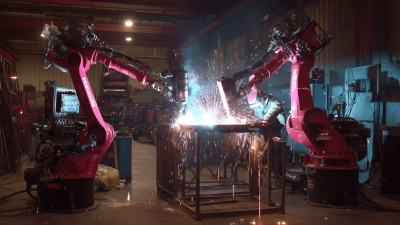

The packaging industry is undergoing a transformative phase with the introduction of innovative technologies that significantly enhance automation processes. Key advancements such as machine learning, computer vision, and predictive analytics are paving the way for smarter packaging solutions. These technologies enable real-time data analysis and operational adjustments, improving the efficiency of production lines. As industries seek to streamline their packaging processes, integrating artificial intelligence into operations becomes essential for maximizing output and minimizing errors.

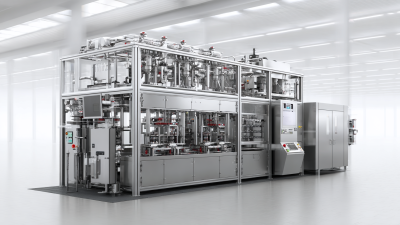

The end-of-line (EOL) packaging segment is particularly noteworthy, as it encompasses the crucial final packaging stages that ensure products are ready for shipment. Innovations in this area focus on automation technologies that can quickly adapt to varying product sizes and shapes, thereby speeding up the packaging process and reducing downtime. With the projected growth of the EOL packaging market, companies are increasingly investing in automated solutions that not only enhance speed and accuracy but also improve overall supply chain operations. These developments reflect a broader trend towards digitization and efficiency in modern manufacturing.

The integration of automation in packaging processes has emerged as a game changer for modern industries, delivering significant efficiency gains and cost reductions. According to a report by the PMMI, The Association for Packaging and Processing Technologies, the global market for automated packaging solutions is projected to grow at an annual rate of 4.4%, reaching $62 billion by 2026. This growth is driven by the need for faster production speeds, improved quality, and reduced labor costs. Automated packaging lines minimize human error, ensure consistent product quality, and enhance safety in the workplace.

Tips for industries looking to innovate their packaging processes include starting with a comprehensive assessment of current workflows to identify bottlenecks. By adopting automated systems, businesses can reduce packaging time by up to 30%, allowing for quicker response to market demands. Additionally, utilizing data analytics in automation can provide insights for optimizing operations, further enhancing productivity.

Another benefit of integrating automation is the sustainability factor. Automated packaging solutions often utilize materials more efficiently, leading to reduced waste. A study by the International Society of Automation reveals that companies integrating sustainable automated processes can reduce their operational costs by approximately 20%. Therefore, investing in automated packaging not only streamlines operations but also aligns with modern sustainability goals.

The implementation of automated packaging solutions is becoming increasingly essential for modern industries striving for efficiency and reliability. By leveraging cutting-edge technologies, businesses can significantly reduce manual labor, streamline operations, and enhance product consistency. Automation not only increases speed but also minimizes errors associated with human intervention, leading to higher-quality output.

**Tips for Implementing Automated Packaging Solutions:**

1. **Assess Your Needs:** Begin by thoroughly analyzing your packaging process to identify areas where automation can provide the most benefit. Consider factors such as production volumes, package types, and existing bottlenecks.

2. **Choose the Right Technology:** Invest in the right equipment and technology that align with your specific needs. Options range from robotic systems to integrated software for tracking and managing the entire packaging line.

3. **Train Your Staff:** Ensure that your workforce is well-trained in using new automated systems and understands the benefits of these innovations. This facilitates smoother transitions and enhances overall productivity.

By emphasizing best practices in automation, companies can harness the benefits of automated packaging solutions, leading to greater operational efficiency and improved customer satisfaction.

| Dimension | Value |

|---|---|

| Average Packaging Cycle Time | 5 seconds |

| Efficiency Improvement | 30% |

| Automation ROI Period | 18 months |

| Reduction in Labor Costs | 40% |

| Maintenance Frequency | Monthly |

| User-Friendly Interface Rating | 4.5/5 |

| Integration with Other Systems | Yes |

| Common Packaging Materials Used | Cardboard, Plastic, Glass |

| Typical Output per Hour | 600 units |

| Adoption Rate of Automated Solutions | 75% |

The future of automated packaging technologies is poised for remarkable advancements, focusing on unlocking efficiency across modern industries. According to a recent report, the industrial automation market is expected to reach significant milestones, with the global food automation sector projected to grow from $8.98 billion in 2025 to $12.2 billion by 2033, achieving a compound annual growth rate of 3.9%. This growth reflects the increasing sophistication of production processes and the rising demand for high-quality, efficient packaging solutions.

As industries embrace automation, several key trends are surfacing, notably AI-driven warehouse management and sustainable packaging solutions. These innovations not only enhance operational efficiency but also reduce costs significantly. For instance, DHL's commitment to improving logistics through AI predictions and last-mile delivery technologies demonstrates the shifting landscape aimed at boosting efficiency for startups.

**Tips:**

1. Invest in technologies that integrate AI into packaging lines to optimize resource utilization and reduce waste.

2. Stay updated on emerging trends such as sustainable practices that not only meet regulatory requirements but also appeal to environmentally conscious consumers.