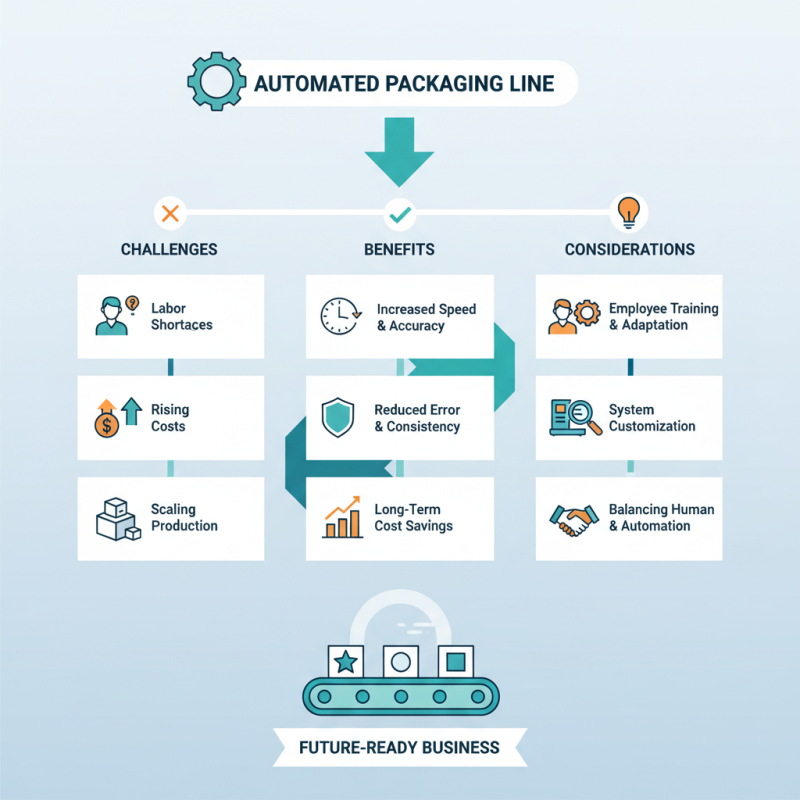

In today’s fast-paced market, businesses strive for efficiency and quality. An automated packaging line can be a game-changer. Many industries face challenges like labor shortages, rising costs, and scaling production. These hurdles drive the need for innovation in packing solutions.

An automated packaging line streamlines the entire process. It improves speed and accuracy while reducing human error. Imagine a factory where products are wrapped and labeled meticulously, leaving no room for mistakes. It’s not just about speed; it’s about reliability and consistency. While the initial investment may appear daunting, the long-term benefits outweigh this concern.

However, transitioning to automation may feel overwhelming. Employees might fear job loss, and training may take time. Each automated system requires assessment and fine-tuning to meet specific needs. Balancing automation and human input is crucial. A thoughtful approach can help businesses thrive in competitive markets.

Automation in packaging processes brings numerous advantages to businesses. Efficiency is a primary benefit. Automated systems can operate continuously without breaks. This means faster production times and increased output. Additionally, accuracy is improved with automation. Machines minimize human error, ensuring products are packaged consistently. Lowering the likelihood of mistakes saves both time and resources.

Another notable benefit is cost-effectiveness. While initial investment in automation may seem high, long-term savings are significant. Reduced labor costs ultimately help the bottom line. Moreover, automation can adapt to various packaging needs, enhancing flexibility. This is vital in a fast-changing market with diverse products. However, not every business may find automation suitable right away. It requires thorough evaluation to ensure proper implementation.

The technology also allows for better data collection. Automated systems can track production metrics in real-time. This data can pinpoint inefficiencies and guide improvements. Yet, integrating new systems poses challenges. Workers may need training to adapt to new technologies. Resistance to change can slow down progress, necessitating careful management. Balancing human and machine capabilities is essential for optimal results.

| Benefit | Description | Impact on Business |

|---|---|---|

| Increased Efficiency | Automation speeds up the packaging process, allowing for higher output in less time. | Higher production rates can lead to increased sales and revenue. |

| Cost Savings | Reduced labor costs and waste through precision and speed. | Lower operational costs improve profit margins. |

| Consistent Quality | Automated processes ensure uniformity, reducing the likelihood of defects. | Enhanced product quality can increase customer satisfaction and loyalty. |

| Flexibility | Modern automated systems can easily be reconfigured for different products. | Ability to adapt to market trends and customer needs. |

| Improved Safety | Automation reduces the risk of accidents associated with manual handling. | Safer work environments can reduce liability and insurance costs. |

| Data Tracking | Automated systems provide valuable data on production runs and inefficiencies. | Data insights enable better decision-making and process improvements. |

Automated packaging lines have become increasingly popular for businesses seeking cost efficiency. According to a report from Smithers Pira, companies can save up to 25% on packaging costs by automating their processes. This shift allows businesses to redeploy labor to more strategic areas, improving overall productivity.

Labor costs can significantly impact a company's bottom line. A 2021 study highlighted that companies using automated solutions saw a 30% reduction in labor expenses. They also reported a faster packaging speed, which can lead to higher output. However, the initial investment in automation can be daunting. It requires careful consideration and planning.

Moreover, businesses may encounter challenges when transitioning from manual to automated systems. There can be a steep learning curve for employees. Some companies struggle to adapt to the new technology. Yet, the potential savings are undeniable. With careful analysis, companies can pinpoint areas for improvement and maximize efficiency.

Automation in packaging is transforming how businesses operate. A recent report from the Packaging Automation Association noted that automated lines can improve speed by over 30%. This efficiency leads to consistent product output. When products are packaged the same way every time, customers receive reliable quality. Customers often prefer brands that deliver uniformity.

Additionally, automated systems reduce human error. A study by the International Society of Automation indicates that manual packaging processes can have error rates as high as 30%. Even minor deviations can lead to significant waste and customer dissatisfaction. With sensors and monitoring technology, automated lines ensure products are sealed correctly, labeled accurately, and packaged efficiently.

However, implementing automation is not without challenges. Initial costs can be high. Smaller businesses may struggle to justify these investments. Maintenance also requires skilled personnel who can troubleshoot issues. Training staff involves time and resources. Despite this, the long-term benefits often outweigh the hurdles. Maximizing product consistency and quality can boost customer loyalty and improve overall efficiency for businesses willing to adapt.

Automated packaging lines are reshaping the way businesses think about labor costs and safety. By integrating machines into the packaging process, businesses can significantly reduce the number of labor hours required. This shift minimizes overtime expenses and lowers overall payroll costs. Workers who once spent hours packaging products can now focus on other essential tasks.

Safety is another crucial aspect of automation. Manual packaging can be risky. Workers face the potential for repetitive strain injuries or accidents with heavy equipment. Automated systems handle these tasks, making the environment safer for employees. This change not only reduces workplace injuries but can also lead to higher morale among staff. Happier employees are often more productive in their roles.

Though automated packaging lines can require a significant initial investment, the long-term benefits outweigh these costs. However, there are challenges. Workers may need training to adapt to new technology. Transitioning can also disrupt daily operations. It is essential to evaluate these aspects carefully. Not all businesses may be ready for this shift. Investing in automation should be a thoughtful decision.

Automated packaging lines offer remarkable flexibility and scalability for businesses. They adapt easily to various product sizes and shapes. This adaptability means companies can introduce new items without a complete system overhaul. Production can shift from small batches to high-volume runs seamlessly. It makes responding to market demands less stressful.

The scalability of these systems is another major benefit. As demand grows, businesses can expand their packaging capacity without significant downtime. Adding modules to existing lines is often straightforward. This can be done without losing efficiency. However, selecting the right system requires careful consideration. A mismatch might lead to underperformance or higher costs.

Investing in automated packaging does pose challenges. Companies may need to train staff on new technologies. Some systems could be complex, leading to initial resistance. It's essential to assess the specific needs and limitations of your operation. Balancing flexibility with the technical demands of automation can be difficult yet rewarding.