In the ever-evolving landscape of packaging technology, the demand for advanced solutions persists, with form fill machines playing a pivotal role in enhancing operational efficiency. As industry expert Dr. Sarah Thompson, a leading authority on automated packaging systems, remarked, “Investing in state-of-the-art form fill machines not only streamlines production processes but also significantly reduces costs over time.” This insight underscores the critical function that form fill machines serve in modern manufacturing environments.

As we delve into the top five form fill machines for 2025, it's essential to recognize how these innovations revolutionize the packaging sector. From increasing speed and precision in filling products to facilitating seamless integration with existing production lines, these machines offer an array of features that cater to diverse industry needs. Whether for food, pharmaceuticals, or consumer goods, the right form fill machine can transform packaging operations, driving both productivity and profitability.

In this article, we will explore the leading models that promise to elevate your packaging efficiency to new heights. By examining their unique capabilities, performance metrics, and user feedback, we aim to provide valuable insights to help businesses stay competitive in a rapidly advancing market.

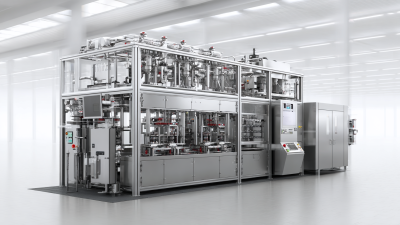

In the rapidly evolving landscape of packaging technology, the form fill machines of 2025 stand out for their innovative features that significantly enhance operational efficiency. One of the most notable advancements is the integration of AI-driven analytics, which allows machines to adapt in real-time to varying production demands. These intelligent systems can optimize filling speeds and reduce material waste, ensuring that manufacturers not only meet their throughput goals but also operate sustainably.

Additionally, the latest form fill machines are equipped with user-friendly interfaces that simplify training and operation. Touchscreen controls and intuitive software enable operators to make adjustments quickly and accurately, reducing downtime and increasing overall productivity. Coupled with enhanced safety features such as automatic shut-off and maintenance alerts, these machines not only improve efficiency but also foster a safer working environment. As businesses continue to seek competitive advantages, embracing these cutting-edge technologies is essential for staying ahead in the packaging industry.

In the fast-paced world of packaging, the efficiency of form fill machines plays a crucial role in optimizing production lines. This comparative analysis examines the top five form fill machines of 2025, focusing on their performance metrics, speed, and adaptability to various packaging needs. Each model's capability to handle diverse materials and formats offers businesses critical insights into which machine aligns best with their operational goals.

The first machine showcases remarkable speed and precision, boasting up to 120 packs per minute, making it ideal for high-volume environments. Conversely, another machine prioritizes versatility, seamlessly switching between different package sizes without compromising efficiency. Additionally, the integration of advanced technology in these machines allows for real-time monitoring and adjustments, ensuring consistent quality and reducing downtime. As businesses aim to elevate their packaging efficiency, understanding these key differences will guide them in making informed decisions tailored to their specific requirements.

Investing in form fill technology not only boosts packaging efficiency but also ensures significant cost-effectiveness and return on investment (ROI). According to a recent report by Smithers Pira, the global packaging machinery market is projected to reach USD 50 billion by 2025, driven largely by innovations in automation and efficiency. Businesses that integrate advanced form fill machines into their production lines can expect to reduce labor costs by up to 30%, as these systems automate repetitive tasks and minimize human intervention.

Additionally, the rapid advancements in machine technology have resulted in higher throughput rates. According to a study by MarketsandMarkets, implementing modern form fill systems can increase packaging speed by up to 50%, allowing companies to meet growing consumer demand without compromising on quality. The initial investment in these machines is often recouped within a year due to the operational savings and increased productivity. Hence, for businesses aiming to stay competitive in the packaging sector, investing in form fill technology is essential for not only enhancing efficiency but also improving overall profitability.

In 2025, the evolution of form fill machines is set to focus not only on efficiency but also on enhancing the operator experience. User-friendly designs are pivotal in ensuring that operators can navigate complex machinery with ease. The latest models incorporate intuitive touchscreens and simplified controls that streamline the packaging process. By prioritizing ergonomic features, manufacturers are reducing fatigue and enhancing productivity, allowing operators to focus on quality rather than struggling with complicated setups.

Tips for selecting a user-friendly form fill machine include looking for models with customizable interfaces that cater to specific operational needs. Additionally, consider machines that offer real-time training modules or tutorials, which can significantly assist new operators in becoming proficient quickly. Another recommendation is to choose equipment with easy-to-access maintenance points, as this not only saves time during routine checks but also minimizes downtime for repairs.

The emphasis on operator experience extends to safety features as well. Machines with automatic shut-off mechanisms or emergency stop buttons can create a safer working environment. Investing in equipment that prioritizes user and operator interaction can ultimately lead to fewer errors and a smoother workflow, driving overall packaging efficiency.

As the packaging industry continues to evolve, the trends in form fill machines are significantly influenced by advancements in technology and consumer demand. According to a report by Smithers Pira, the global packaging machinery market is expected to reach $50 billion by 2025, with form fill machines playing a pivotal role in this growth. This rise is fueled by the increasing need for efficiency and automation in manufacturing processes, allowing companies to enhance their productivity and reduce labor costs.

One notable trend is the integration of smart technology into form fill machines. These machines are now equipped with IoT capabilities, enabling real-time monitoring and data collection. A study from MarketsandMarkets forecasts that the smart packaging market will grow from $23 billion in 2020 to over $46 billion by 2025, showcasing the industry's shift towards intelligent solutions. Furthermore, sustainability is becoming a driving force in the packaging sector. With more consumers demanding eco-friendly practices, manufacturers are prioritizing the use of recyclable materials and energy-efficient machinery, aligning with the global push for sustainable development. This trend not only meets consumer expectations but also allows companies to comply with stricter environmental regulations.

| Machine Model | Filling Speed (units/min) | Accuracy (%) | Compatibility | Key Features |

|---|---|---|---|---|

| Model A | 100 | 99 | Liquid | Auto-cleaning, touchscreen control |

| Model B | 120 | 98 | Powder | Smart sensors, adjustable speed |

| Model C | 90 | 97 | Granular | Flexible filling, low maintenance |

| Model D | 80 | 96 | Liquid & Powder | Multi-purpose, energy efficient |

| Model E | 110 | 95 | Solid | Robust design, quick changeover |