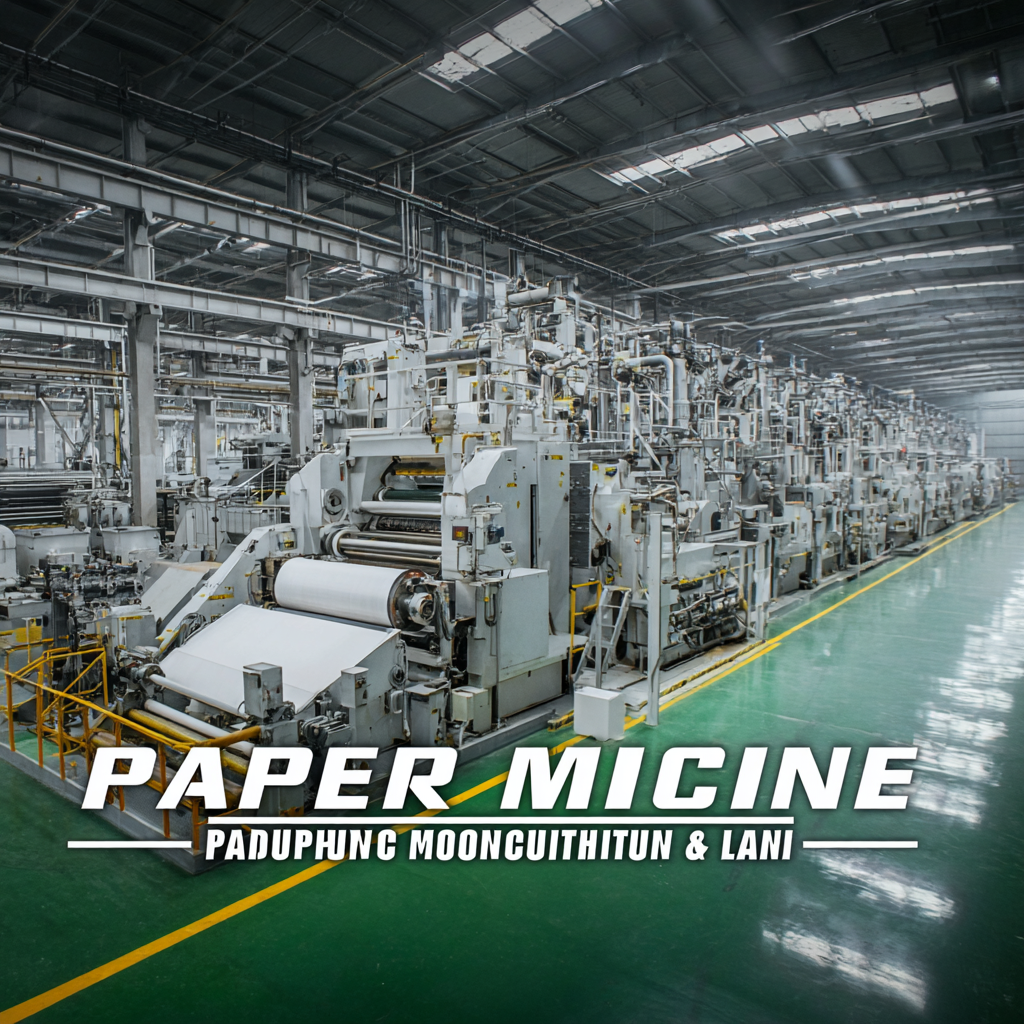

Unlocking Global Opportunities: Trustworthy Paper Machine Production Lines from China

In today's rapidly evolving paper industry, the demand for high-quality and efficient Paper Machine Production Lines is more critical than ever. According to a recent report by the Research Institute of Paper Industry, the global paper production is projected to reach approximately 500 million tons by 2025, driven by increasing consumption across various sectors such as packaging, tissue, and specialty papers. As Chinese manufacturers continue to innovate and enhance their production capabilities, they are becoming key players in supplying reliable and advanced Paper Machine Production Lines. With a focus on sustainability and technology, these production lines not only meet the rising global demand but also comply with stringent environmental regulations. By exploring the trustworthy options available from China, businesses can unlock global opportunities and ensure they remain competitive in the international market.

Harnessing Industry 4.0: The Future of Paper Machine Production Lines in China

In the era of Industry 4.0, the evolution of paper machine production lines in China is making a significant impact on the global manufacturing landscape. With the advent of smart technologies such as the Internet of Things (IoT) and artificial intelligence (AI), traditional paper manufacturing processes are rapidly transforming into intelligent production systems. This shift allows for enhanced efficiency, improved quality control, and more flexible production capabilities, aligning with the overarching goal of digital transformation in the manufacturing sector.

Chinese companies are increasingly investing in intelligent manufacturing, exemplified by advancements in automation and data analytics. Modern paper machine production lines not only emphasize production capacity but also harness real-time data to optimize operations and predict maintenance needs. As the industry embraces smart technologies, it is setting a benchmark for global partnerships and opening new avenues for international collaboration. As a result, businesses worldwide are looking towards China as a key player in the future of intelligent paper production, promising mutual growth and innovation in the global marketplace.

Emerging Technologies Shaping the Paper Industry by 2025: A Data-Driven Overview

As we approach 2025, the paper industry is set to undergo significant transformations driven by emerging technologies. Innovations such as artificial intelligence, automation, and advanced data analytics are reshaping production lines, leading to enhanced efficiency and sustainability. These technologies enable manufacturers to monitor production in real-time, optimize workflows, and reduce waste, creating a more environmentally friendly paper production process.

**Tip: Embrace Automation**

Investing in automated machinery can drastically cut down operational costs and minimize human error during production. By integrating smart systems that manage inventory and oversee production schedules, companies can streamline their processes, leading to faster turnaround times and higher quality products.

The rise of sustainable practices in the paper industry is also noteworthy. As consumers prioritize eco-friendly products, manufacturers must adapt by incorporating recycled materials and reducing their carbon footprint. Enhanced recycling technologies not only meet consumer demand but also contribute to a circular economy within the industry.

**Tip: Focus on Sustainability**

Fostering partnerships with suppliers who prioritize sustainability can enhance your credibility. By sourcing eco-friendly materials and adopting green practices, businesses can appeal to a growing demographic of environmentally-conscious consumers, ultimately driving sales and reputation in a competitive market.

Sustainability Trends in Paper Machine Manufacturing: Meeting Global Standards

The paper machine manufacturing industry is undergoing a significant transformation driven by sustainability trends and global standards. According to a report from Smithers Pira, the demand for sustainable paper production methods is projected to grow by 4.5% annually over the next five years. This shift is largely influenced by stricter environmental regulations and an increasing consumer preference for eco-friendly products. Manufacturers in China are adapting to these trends by investing in advanced technologies that reduce waste and energy consumption, ensuring their production lines meet the high standards set by international markets.

Furthermore, the integration of circular economy principles into paper machine production is becoming a priority. The Paper and Forest Products Industry Council (PFPIC) indicates that adopting sustainable practices can drive savings of up to 30% in energy usage during production processes. By utilizing recycled materials and optimizing resource allocation, Chinese manufacturers are not only improving their operational efficiencies but also enhancing their market competitiveness. These advancements ensure that they can provide reliable and environmentally responsible production lines that cater to the global demand for sustainable paper products.

The Role of Automation in Enhancing Efficiency in Paper Production Lines

In the fast-evolving world of paper production, automation has emerged as a key driver in enhancing operational efficiency. Modern paper machine production lines increasingly incorporate advanced automation technologies, which streamline various processes and reduce human error. By utilizing automated controls, manufacturers can achieve precise monitoring of production parameters, ensuring consistent quality while minimizing waste. This technological leap not only boosts productivity but also optimizes resource usage, which is crucial for sustainable practices in the paper industry.

Moreover, automation facilitates real-time data collection and analysis, empowering operators to make informed decisions swiftly. With sophisticated sensors and control systems, these production lines can adjust to fluctuations in material quality and production demands, thus maximizing uptime and efficiency. As companies worldwide look for ways to stay competitive, the integration of automation in paper production lines represents a pivotal move toward meeting increasing market demands while adhering to stringent quality standards. The ongoing advancements in automation technology position manufacturers to seize global opportunities, particularly in a market where reliability and efficiency are paramount.

Navigating Global Supply Chains: Challenges and Opportunities for Chinese Manufacturers

Navigating global supply chains has never been more challenging, especially for Chinese manufacturers facing ongoing geopolitical tensions and shifting economic landscapes. The complexity of modern supply chains is exemplified by multinational corporations that rely on a vast network of suppliers spanning multiple countries. For instance, producing a single product can involve components sourced from various nations, highlighting the intricate interdependencies that define today’s global economy. However, as manufacturers adapt to the pressures of tariffs and changing trade policies, they are compelled to rethink their strategies and optimize their supply chains.

Navigating global supply chains has never been more challenging, especially for Chinese manufacturers facing ongoing geopolitical tensions and shifting economic landscapes. The complexity of modern supply chains is exemplified by multinational corporations that rely on a vast network of suppliers spanning multiple countries. For instance, producing a single product can involve components sourced from various nations, highlighting the intricate interdependencies that define today’s global economy. However, as manufacturers adapt to the pressures of tariffs and changing trade policies, they are compelled to rethink their strategies and optimize their supply chains.

Chinese manufacturers are uniquely positioned to unlock global opportunities by leveraging their capabilities to innovate and streamline operations. By focusing on supply chain optimization, they can reduce vulnerabilities and enhance resilience in the face of disruptions. For example, investing in technology and fostering partnerships can enable manufacturers to adapt quickly to market shifts and maintain their competitive edge. As global supply chains continue to evolve, the ability to navigate these challenges while seizing new opportunities will be crucial for Chinese producers aiming to thrive in a dynamic international environment.