10 Tips for Achieving Best Precision Machining in Your Global Supply Chain

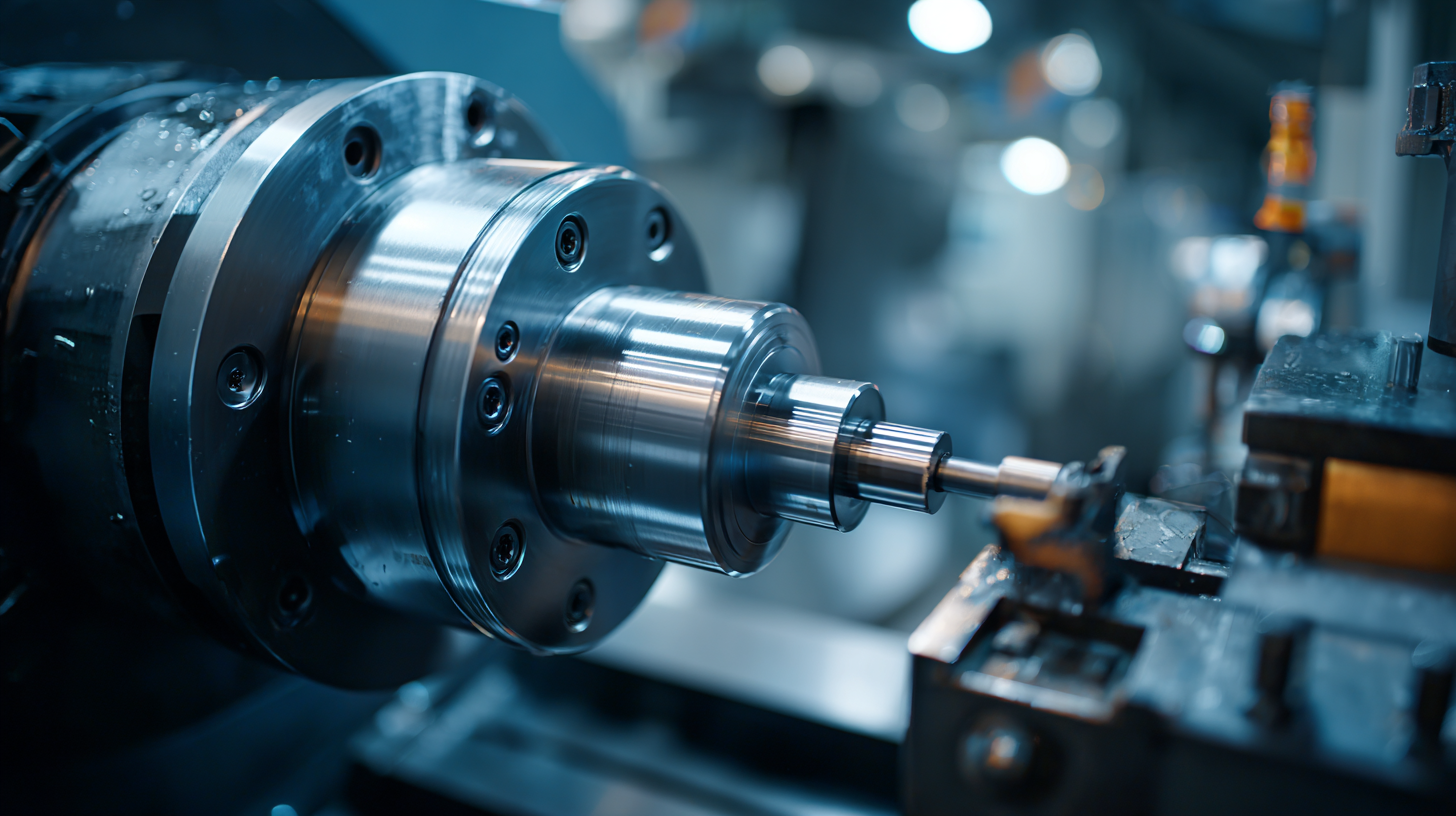

In an increasingly competitive global marketplace, achieving excellence in precision machining is essential for manufacturers aiming to establish themselves at the forefront of international supply chains. Precision machining refers to the process of removing material from a workpiece to achieve extremely tight tolerances and surface finishes, essential for high-quality production across various industries.

As companies strive for global recognition, optimizing machining processes is critical not just for performance but also for enhancing efficiency and reducing costs. This blog will explore ten essential tips that can help manufacturers improve their precision machining capabilities, enabling them to stand out as leading factories in the global arena.

By implementing these strategies, businesses can not only refine their production methods but also contribute to a more robust and responsive supply chain, ultimately positioning themselves at the top of their game.

Maximizing After-Sales Service Efficiency in Global Precision Machining

In the realm of global precision machining, after-sales service plays a pivotal role in ensuring client satisfaction and operational efficiency. The complexity of precision components requires not only precise manufacturing but also a robust support system that addresses client needs post-delivery. Establishing a responsive after-sales service team can significantly enhance customer trust and loyalty, as they provide essential support for troubleshooting, maintenance, and parts replacement.

To maximize after-sales service efficiency in global precision machining, companies should implement comprehensive training programs for their support staff, ensuring they are well-versed in the intricacies of the products they represent. Additionally, leveraging technology such as customer relationship management (CRM) systems can streamline communication and tracking of service requests. Regular feedback loops from customers can identify areas for improvement, allowing companies to adapt their services proactively. By prioritizing after-sales efficiency, businesses can not only resolve issues more swiftly but also foster long-term partnerships with clients, securing a competitive edge in the global market.

10 Tips for Achieving Best Precision Machining in Your Global Supply Chain - Maximizing After-Sales Service Efficiency in Global Precision Machining

| Tip Number | Tip Description | Expected Outcome | Implementation Cost | Timeframe for Implementation |

|---|---|---|---|---|

| 1 | Standardize Machining Processes | Improved consistency and quality | Medium | 3 months |

| 2 | Invest in High-Quality Tools | Enhanced precision and lifespan | High | Immediate |

| 3 | Implement CAD/CAM Technology | Increased design speed and accuracy | Medium | 6 months |

| 4 | Regular Maintenance of Equipment | Reduction in downtime | Low | Ongoing |

| 5 | Set Up Quality Control Measures | Higher quality final products | Medium | 1 month |

| 6 | Train Employees Regularly | Improved skills and efficiency | Low | Ongoing |

| 7 | Utilize Lean Manufacturing Techniques | Streamlined operations | Medium | 4 months |

| 8 | Optimize Supply Chain Management | Reduced lead times and costs | High | 5 months |

| 9 | Implement Robust After-Sales Services | Increased customer satisfaction | Medium | 3 months |

| 10 | Regular Review and Feedback | Continuous improvement | Low | Ongoing |

Minimizing Repair Costs: Strategies for Sustainable Supply Chains

In today's competitive manufacturing landscape, minimizing repair costs is critical for sustaining a robust supply chain. According to a report by the National Institute of Standards and Technology (NIST), companies can save up to 25% on production costs by implementing precision machining techniques. This emphasizes the importance of investing in high-quality machining processes to reduce defects and subsequent repairs.

Integrating advanced technologies such as predictive maintenance and real-time monitoring can further enhance operational efficiency. A study by McKinsey & Company reveals that predictive maintenance can reduce downtime by 30-50%, significantly lowering repair expenses and enhancing overall productivity. By focusing on precision and utilizing data analytics, manufacturers can foster a more sustainable supply chain, ensuring their operations remain not only cost-effective but also environmentally friendly, as efficient machining often leads to reduced waste and energy consumption.

Leveraging Technology for Precision and Reliability in Machining Services

In today's competitive market, leveraging technology is crucial for achieving precision and reliability in machining services. Advanced machining capabilities often hinge on the adoption of cutting-edge software and hardware, which not only enhance accuracy of operations but also streamline processes. For instance, implementing CAD/CAM systems allows manufacturers to create precise designs that can be directly translated into machine instructions, reducing the likelihood of error and improving overall efficiency. Additionally, automation technologies, such as CNC machines, contribute to consistent quality and reduced lead times, making it easier to meet global supply chain demands.

Data analytics and IoT (Internet of Things) also play a vital role in enhancing machining processes. By collecting real-time data from machinery, companies can monitor performance, predict maintenance needs, and make informed decisions to optimize production. This level of insight allows for quick adjustments to be made, ensuring that machining operations remain on schedule and within quality specifications. Furthermore, integrating cloud-based solutions can facilitate collaboration across global supply chains, enabling teams to share information and coordinate efforts more effectively. In this tech-driven landscape, embracing innovative tools will be essential for manufacturers looking to achieve the highest levels of precision and reliability in their machining services.

Future Trends in Precision Machining: Innovations Shaping the Global Market

The landscape of precision machining is rapidly evolving, driven by technological innovations and global market demands. Key trends are shaping this industry, including the adoption of advanced materials, automation, and artificial intelligence. These innovations not only enhance the quality of machining processes but also increase efficiency across supply chains worldwide. By staying ahead of these trends, manufacturers can ensure they remain competitive in a fast-paced market.

To achieve optimal precision machining, businesses must prioritize integration and communication within their supply chains. One essential tip is to invest in CNC (Computer Numerical Control) technology, which allows for superior accuracy and repeatability in machining processes. Additionally, fostering collaboration with suppliers and utilizing data analytics can lead to better insights into production workflows, allowing for timely adjustments that enhance precision and reduce waste. Embracing these strategies will position companies to navigate future challenges and capitalize on emerging opportunities in the precision machining sector.

Another important consideration is the implementation of smart manufacturing solutions. By leveraging IoT devices, companies can monitor equipment performance in real-time, leading to predictive maintenance and reduced downtime. Furthermore, exploring additive manufacturing alongside traditional machining processes can open new avenues for innovation and cost savings. As the global market for precision machining evolves, these practices will be crucial for success.

Enhancing Communication Across Global Supply Chains for Better Precision Outcomes

Effective communication is essential for enhancing precision in machining throughout global supply chains. According to a report from Deloitte, clear communication between stakeholders can increase supply chain agility by up to 25%. When different teams, whether they are located in Europe, Asia, or the Americas, maintain an open dialogue, they are better equipped to address challenges such as delays or quality discrepancies promptly. This proactive approach leads to improved coordination and alignments, resulting in better precision machining outcomes.

Moreover, utilizing advanced communication technologies can help bridge geographical gaps and facilitate real-time collaboration. A recent survey by PwC found that companies that invest in integrated communication tools see a 35% improvement in project delivery times. By fostering a culture of transparency and collaboration across global teams, businesses can systematically refine their machining processes, ensuring that precision and quality are upheld at every stage of production. As the demand for high-quality components continues to rise, particularly in sectors like aerospace and automotive, the importance of robust communication in achieving precision cannot be overstated.