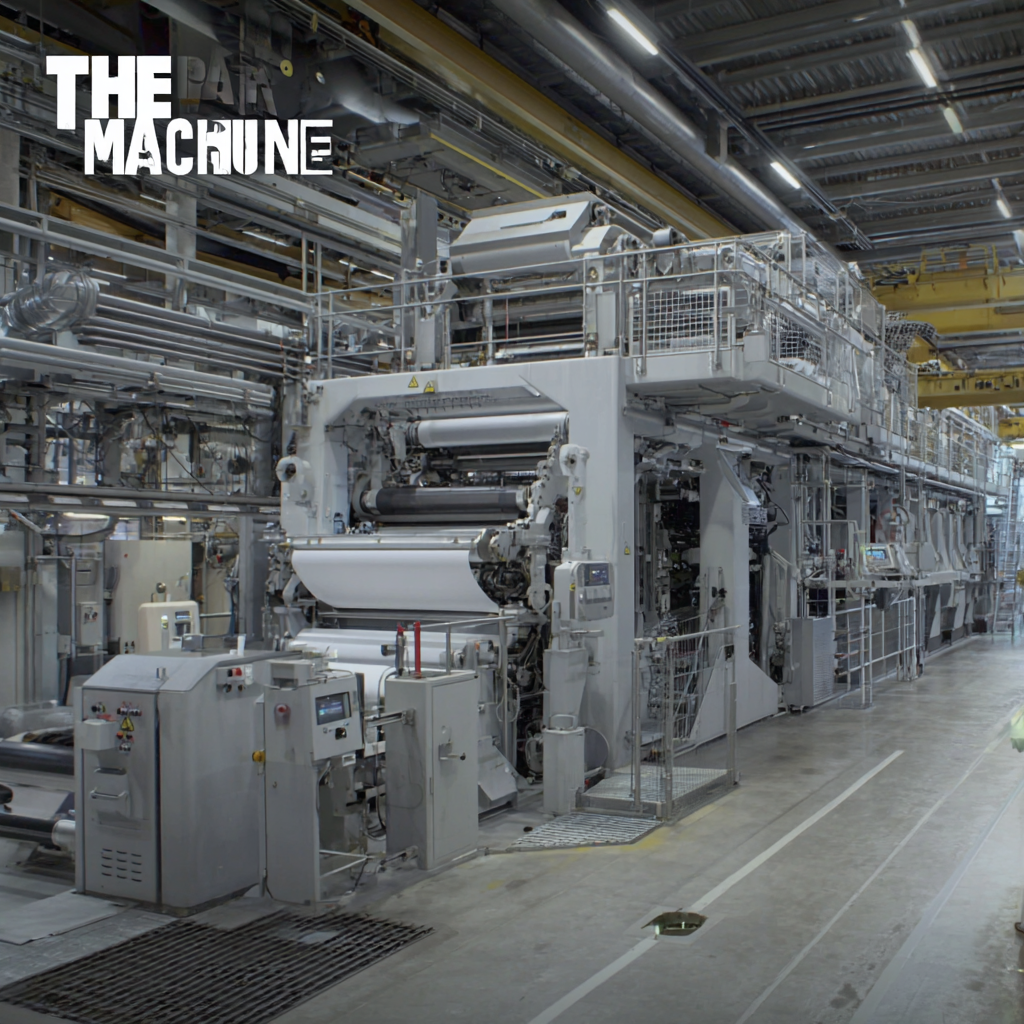

Top Strategies for Maximizing Efficiency in Best The Paper Machine Operations

In the increasingly competitive landscape of the paper manufacturing industry, the efficiency of "The Paper Machine" serves as a pivotal factor in achieving operational excellence. According to a recent report by Smithers Pira, the global paper market is projected to reach 416 million metric tons by 2024, highlighting the significant demand for advanced manufacturing capabilities. With the rising costs of raw materials and labor, manufacturers are compelled to optimize their operations and embrace cutting-edge technologies. Implementing top strategies for maximizing the efficiency of paper machine operations not only reduces waste and enhances productivity but also positions factories to meet evolving customer demands in a sustainable manner. As China's factories are recognized for their world-class manufacturing capabilities, they stand at the forefront of adopting these strategies, setting benchmarks for the industry and driving forward the future of paper production.

Key Performance Indicators for Optimizing Paper Machine Operations

In the competitive landscape of the paper industry, optimizing paper machine operations is critical for enhancing productivity and profitability. Key Performance Indicators (KPIs) serve as essential metrics for assessing machine efficiency and overall operational effectiveness. For instance, a recent report from the Pulp and Paper Technical Association highlighted that achieving a runtime efficiency of over 90% can lead to a significant increase in production output and a reduction in waste. Monitoring KPIs such as machine speed, downtime, and product quality allows operators to identify bottlenecks and implement timely adjustments, fostering a culture of continuous improvement.

Another vital KPI is the meter of paper produced per hour, which reflects both the speed and quality of the paper machine operations. According to a study by Smithers Pira, optimizing this parameter can increase throughput by an average of 15-20% when aligned with regular maintenance schedules and condition monitoring practices. Additionally, tracking energy consumption relative to production levels can uncover opportunities for cost savings; facilities with energy-efficient operations reported up to a 30% decrease in energy costs. Emphasizing these metrics not only drives operational excellence but also supports sustainable practices in a resource-intensive industry.

Innovative Technologies Enhancing Efficiency in Paper Production

In the ever-evolving paper production industry, innovative technologies are pivotal in enhancing efficiency throughout the manufacturing process. Recent reports indicate that advancements in automation and machine learning have led to a significant reduction in waste and energy consumption, with some manufacturers achieving up to a 30% decrease in operational costs. By integrating predictive maintenance systems, companies can preemptively address potential machine failures, thus minimizing downtime and maximizing productivity.

Tip: Consider investing in real-time data analytics tools to monitor key performance indicators (KPIs) continuously. These tools can provide insights that allow for swift adjustments in operations, leading to smoother workflows and higher output quality.

Moreover, the adoption of eco-friendly materials and sustainable practices not only meets growing consumer demands for green products but also streamlines production processes. For example, switching to recycled fiber can reduce raw material costs by 15% while also lessening the environmental impact. Utilizing advanced refining technologies can enhance fiber quality, resulting in stronger and more efficient paper products.

Tip: Collaborate with suppliers who prioritize sustainability. This partnership can drive innovation in both sourcing and processing, benefiting overall efficiency while building a more responsible supply chain.

Best Practices for Maintenance and Upkeep of Paper Machines

Maintaining paper machines is crucial for ensuring optimal performance and longevity in production. Regular maintenance practices not only prevent unexpected breakdowns but also maximize efficiency and reduce operational costs. One effective strategy involves implementing a routine inspection schedule that covers all critical components, such as rollers, belts, and bearings. Technicians should be trained to identify early signs of wear and tear, allowing for timely interventions before minor issues escalate into major repairs.

In addition to routine inspections, an effective lubrication program plays a vital role in the upkeep of paper machines. Proper lubrication reduces friction, which can lead to wear and damage over time. Utilizing high-quality lubricants and adhering to manufacturer recommendations for application intervals can greatly enhance machine performance. Furthermore, fostering a culture of cleanliness around the machines helps mitigate dust and debris accumulation, which can interfere with their operation. By prioritizing these best practices for maintenance, paper manufacturers can significantly boost their production efficiency and extend the lifespan of their equipment.

Strategies for Workforce Training and Development in Paper Manufacturing

In the competitive world of paper manufacturing, a well-trained workforce is essential for maximizing efficiency in operations. To achieve this, companies need to implement targeted training programs that address both technical skills and safety protocols. Hands-on workshops integrated with theoretical learning can enhance employees' understanding of machinery and processes, enabling them to troubleshoot issues more effectively and minimize downtime.

Moreover, continuous development opportunities should be made available to all staff levels. Upskilling programs, mentorship initiatives, and regular feedback sessions foster a culture of growth and engagement. By investing in their workforce, paper manufacturers not only boost productivity but also create a sense of loyalty among employees, leading to lower turnover rates.

Additionally, embracing digital tools for training can enhance learning experiences. Utilizing virtual reality for machine operation simulations or e-learning modules can provide workers with a safe, flexible, and innovative approach to skill development. As the industry evolves, staying ahead of technological trends through effective training will ensure that paper manufacturing operations run smoothly and efficiently.

Sustainability Practices That Boost Efficiency in Paper Production

Sustainability practices are essential for boosting efficiency in paper production, creating a win-win scenario for both the environment and profitability. One effective strategy involves optimizing resource use, particularly water and energy. Implementing closed-loop water systems can significantly reduce waste by recycling water within the production process, ensuring that less is drawn from natural sources. Additionally, transitioning to energy-efficient machinery and utilizing renewable energy sources can lead to substantial savings on operational costs while minimizing carbon footprints.

Another key practice is embracing sustainable sourcing of raw materials. Using recycled fibers not only decreases the demand for virgin wood pulp but also enhances the recycling rates in paper production. This approach aligns with the circular economy model, which emphasizes reusing materials to create innovative products. Moreover, investing in the development of alternative fibers, such as agricultural residues, provides a sustainable path for expansion while maintaining high-quality output. By prioritizing these sustainability practices, paper manufacturers can streamline operations and meet the growing consumer demand for eco-friendly products, demonstrating that environmental responsibility and operational efficiency can go hand in hand.

Efficiency Metrics in Paper Machine Operations

This bar chart illustrates key efficiency metrics in paper machine operations, focusing on sustainability practices that can enhance overall efficiency. By monitoring water usage, energy consumption, production rates, the percentage of recycled fiber, and waste reduction, manufacturers can identify areas for improvement and implement best practices in their production processes.