The Future of Best Manufacturing Engineering Innovations Driving Industry Growth

The future of manufacturing engineering is poised for a transformative journey, as innovative technologies and methodologies emerge to address longstanding challenges within the industry. In recent years, we have witnessed a surge of advancements that are not only enhancing productivity but also driving sustainable growth. However, the path forward is not without its problems; as new innovations are integrated into manufacturing processes, issues such as workforce adaptation, resource allocation, and supply chain disruptions arise. This blog will explore the various types of manufacturing engineering innovations that are shaping the industry, delving into their potential benefits as well as the obstacles that companies must navigate to fully realize their capabilities. By understanding these dynamics, we can better appreciate how manufacturing engineering continues to evolve and plays a vital role in the future landscape of industrial growth.

The Rise of China’s Manufacturing Sector: Key Growth Drivers and Innovations

China's manufacturing sector is undergoing a transformative period, fueled by innovations and strategic initiatives aimed at high-quality development. Recent reports indicate that the nation's shipbuilding industry, classified as a foundational sector of the marine economy, has maintained robust growth in both technological advancement and production capacity. This growth is part of a broader move towards a modernized industrial system that emphasizes innovation-driven development.

In 2024, China's manufacturing industry is projected to continue thriving, supported by policies that prioritize self-reliance and technological breakthroughs. Reports show that high-quality manufacturing will play a pivotal role, with an emphasis on advancing traditional sectors and integrating new technologies. The introduction of the concept of "new quality productivity" reflects the government's commitment to achieving substantial industrial upgrades.

**Tips:**

- Companies should focus on leveraging technology to enhance productivity and efficiency.

- Prioritize investments in R&D to position your business at the forefront of industry innovations.

- Engage in continuous learning and adaptation to align with evolving market demands and governmental policies.

Emerging Trends in Automation: Revolutionizing China's Manufacturing Landscape

The manufacturing landscape in China is undergoing a remarkable transformation, primarily driven by automation technologies that are re-shaping production processes. With the rise of Industry 4.0, companies are increasingly integrating advanced robotics, artificial intelligence, and the Internet of Things (IoT) into their operations. These innovations are not just enhancing efficiency; they are also enabling manufacturers to maintain higher levels of precision and customization, catering to the growing demand for personalized products.

As automation becomes more prevalent, it has fostered a shift in the labor market within China, where skilled workers are now required to manage and maintain sophisticated machinery. This paradigm shift not only increases productivity but also enhances worker safety and reduces operational costs. In turn, these advancements position Chinese manufacturers to compete more effectively on a global scale, ensuring sustainability and growth in an ever-evolving industrial landscape. The integration of smart technologies is ushering in a new era where agility and responsiveness define successful manufacturing strategies.

Sustainable Manufacturing Practices: How China Leads in Green Innovation

China has emerged as a global leader in green innovation, driving sustainable manufacturing practices that not only enhance productivity but also minimize environmental impact. With its robust investment in renewable energy technologies and eco-friendly production processes, Chinese manufacturers are setting the benchmark for sustainability. Companies are increasingly adopting circular economy principles, focusing on reducing waste and promoting resource efficiency. This approach not only meets regulatory demands but also appeals to environmentally-conscious consumers worldwide.

Moreover, China's commitment to sustainable practices is supported by government policies that incentivize green technology development. The integration of smart manufacturing and Industry 4.0 principles enables businesses to optimize their operations, leading to lower emissions and reduced energy consumption. By embracing automation and data analytics, Chinese manufacturers are not just achieving operational excellence but are also contributing to a greener planet. As other countries look to emulate this model, China's innovations in sustainable manufacturing will undoubtedly influence the industry's future direction.

The Role of Robotics and AI in Enhancing Production Efficiency in China

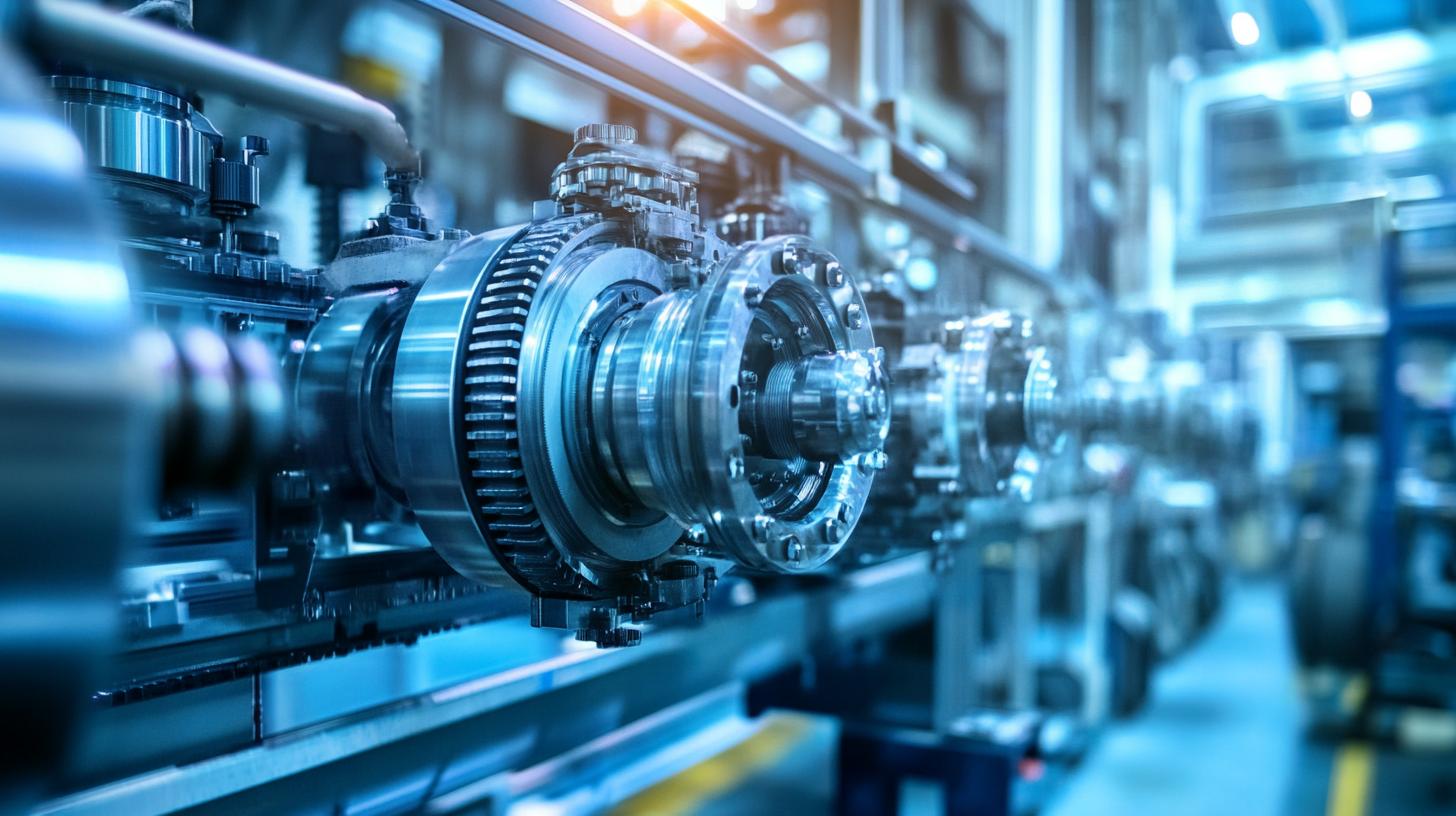

The integration of robotics and artificial intelligence (AI) in manufacturing is revolutionizing production efficiency in China. As industries face increasing demand for faster, higher-quality outputs, the adoption of these technologies is not just beneficial but essential. Robotics streamline repetitive tasks, reducing human error and increasing speed, while AI enhances decision-making processes, predicting maintenance needs and optimizing workflows.

**Tip: Investing in employee training is crucial when implementing new technologies.** Ensuring your workforce is equipped with the necessary skills to operate advanced machinery can lead to greater productivity and job satisfaction. Training programs that focus on both technical skills and problem-solving abilities will prepare teams to adapt to the innovative changes in the manufacturing landscape.

Moreover, utilizing data analytics in conjunction with AI allows manufacturers to gain insights into production processes. This data-driven approach aids in identifying inefficiencies and areas for improvement, leading to substantial cost savings and productivity gains.

**Tip: Regularly analyze production data to pinpoint bottlenecks.** By implementing routine reviews of manufacturing metrics, companies can make informed adjustments that enhance overall performance, driving consistent growth and success in the competitive industry.

The Future of Best Manufacturing Engineering Innovations Driving Industry Growth

| Innovation Category | Description | Impact on Efficiency (%) | Implementation Rate (%) |

|---|---|---|---|

| Robotics | Automation of production processes using robotic arms | 30 | 70 |

| AI in Quality Control | Utilizing AI for defect detection and quality assurance | 25 | 60 |

| Predictive Maintenance | AI-powered analytics to predict equipment failures | 20 | 50 |

| Digital Twins | Creation of digital replicas for simulation and optimization | 15 | 40 |

| Supply Chain AI | AI for efficiency in supply chain management and logistics | 22 | 55 |

Global Export Strategies: How Chinese Manufacturers Are Dominating International Markets

As globalization continues to reshape industries, Chinese manufacturers have emerged as formidable players in international markets. Their success can be attributed to several key strategies that have allowed them to excel in global exports. First and foremost, these manufacturers have significantly invested in advanced technologies, such as automation and artificial intelligence, which enhance production efficiency and quality. This technological edge not only reduces costs but also enables them to meet the varying demands of the global marketplace swiftly.

Furthermore, strategic partnerships and collaborations with international suppliers and distributors have bolstered Chinese manufacturers' competitiveness. By establishing a robust supply chain network, they can better manage resources, streamline operations, and respond to market trends in real time. Additionally, the focus on sustainability and eco-friendly practices is increasingly attracting foreign clients who prioritize responsible sourcing. The combined effect of innovation, strategic partnerships, and sustainable practices positions Chinese manufacturers to dominate the global export landscape, driving the industry toward unprecedented growth.